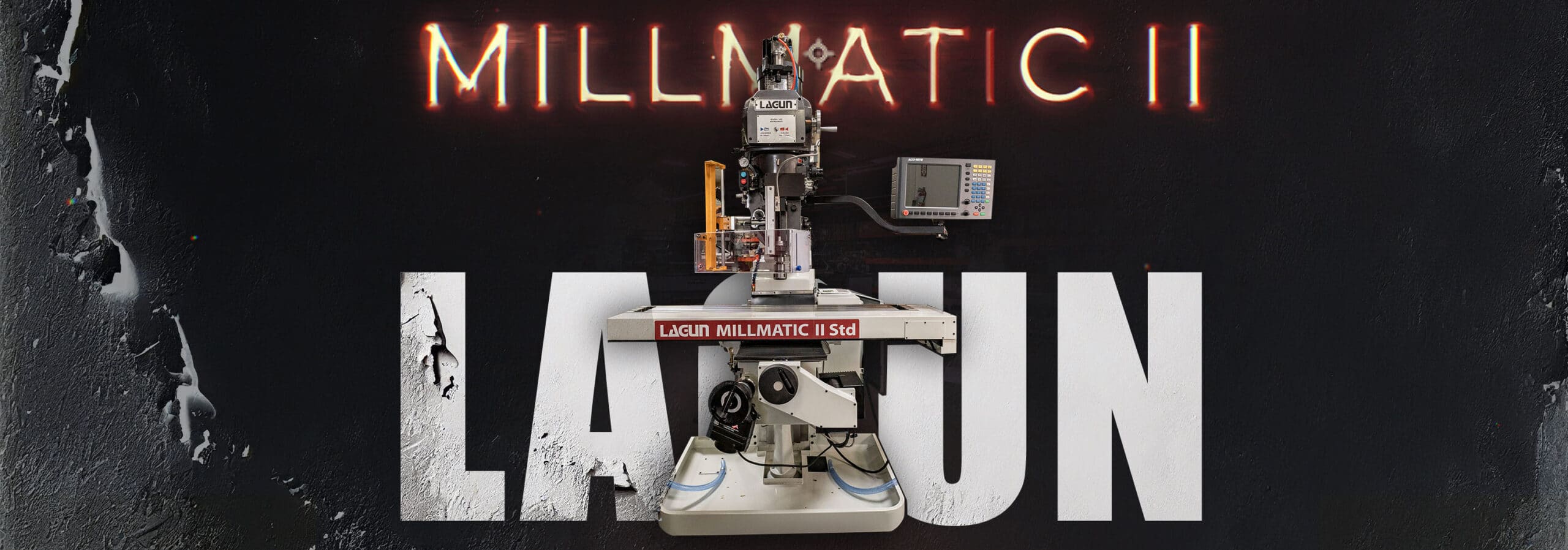

Lagun Millmatic II STD Vertical Knee Mill

The Lagun Engineering Millmatic II is a vertical knee mill that provides a powerful and versatile solution for CNC machining applications. The Millmatic II is designed for precision machining of a wide range of materials, including metals, plastics, and composites.

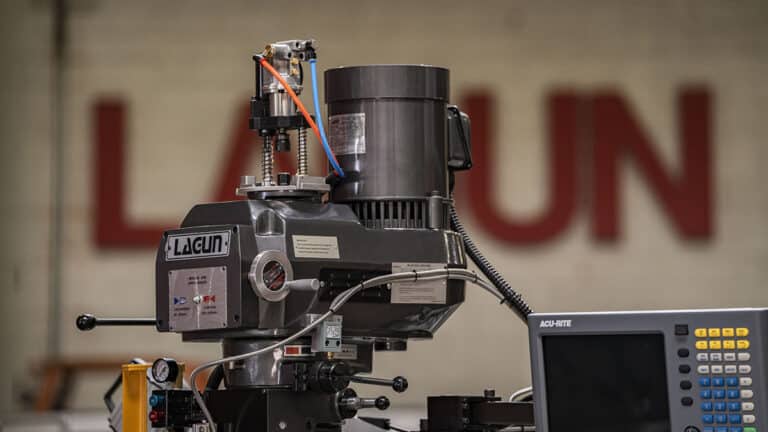

One of the standout features of the Millmatic II is its full 2-axis CNC control. The Fanuc 0i-MF control system is well-known among machinists for its easy-to-use menu-driven conversational programming in machinist language, as well as its full G-code programming capabilities. This gives machinists the flexibility to choose the programming language that best suits their needs, whether they prefer to use conversational programming or G-code.

The Millmatic II is a member of the Lagun FTV family, which has a reputation for reliable service over the past 35 years. The machine features hardened and ground ways on the X, Y, and Z axes, which provide exceptional rigidity and stability. The SQ ways are designed for rigidity, while the dovetail ways provide accuracy. Turcite is applied to the X and Y axis ways to further enhance the machine’s performance.

To ensure high levels of accuracy and repeatability, the Millmatic II features super precision Fafnir class 7 spindle bearings and a precision hard chrome quill. The machine also includes an auto-lubrication system to ensure that all moving parts are properly lubricated, and a flood coolant system to keep the cutting area clean and cool during operation.

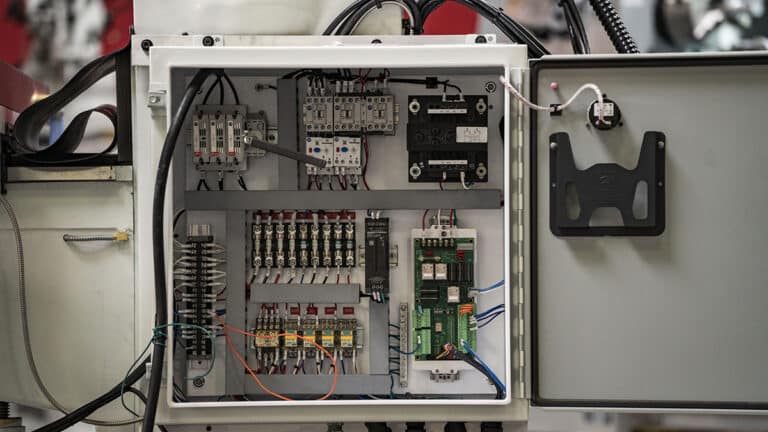

The Millmatic II uses hardened and ground precision ball screws, which are 1 ¼” in diameter on the X and Y axes. This allows for smooth and precise movement, even during high-speed operations. The machine also features a high-performance dual CPU controller design and a 14” color CRT with graphics, making it easy for machinists to monitor and control their machining operations.

Overall, the Millmatic II is an excellent choice for machinists who need a powerful and versatile CNC milling machine. With its range of features and capabilities, it is well-suited for a wide range of applications, from single-shot work to short-run production. The machine’s robust design, high-precision components, and user-friendly control system make it an excellent choice for any machining application.