Experience and reliability in milling technology

Founded in 1928 in northern Spain, Lagun Maher Holding specializes in large, heavy CNC milling equipment. They design high-quality bed mills and traveling columns at reasonable prices, serving sectors like automotive, aeronautics, mold and die, education, and maintenance. Lagun Engineering is proud to be their exclusive US representative.

Milling Machines

We provide a wide range of milling machines with different architectures

-

Bed Type

-

Traveling Column

-

Floor Type

-

T-type

-

Boxed Technology

-

Portable Milling

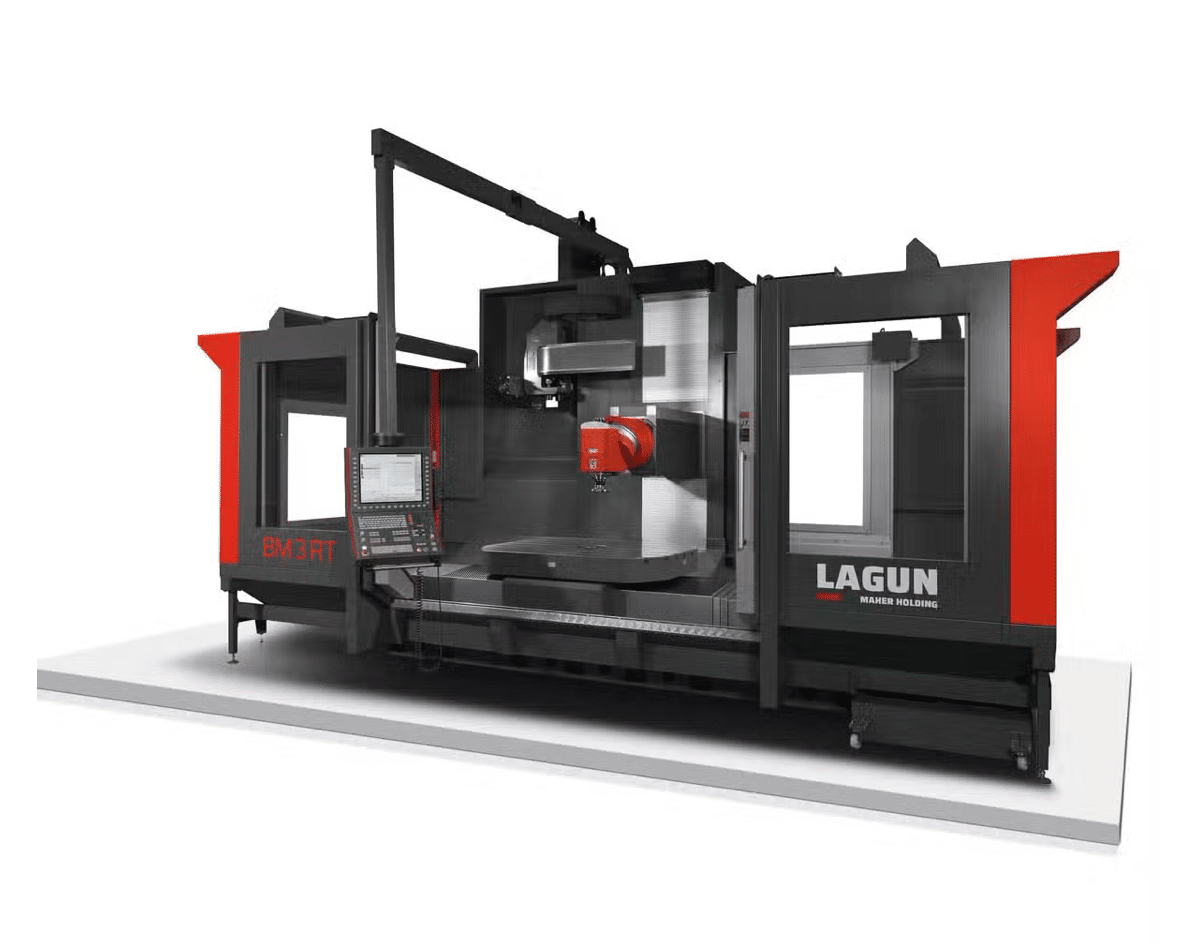

Introducing Lagun’s Bed Type Milling Machines, the epitome of compact precision machining. Designed with an architecture where the part’s movement aligns with one of the machining axes, these machines are engineered for exceptional accuracy and efficiency. Available in three innovative versions—table with linear movement, rotary table, and linear table with an integrated rotary table—our milling machines offer versatile technological solutions to meet diverse machining needs. Each version is meticulously crafted to ensure high profitability, making them an ideal choice for businesses seeking reliable and precise milling capabilities.

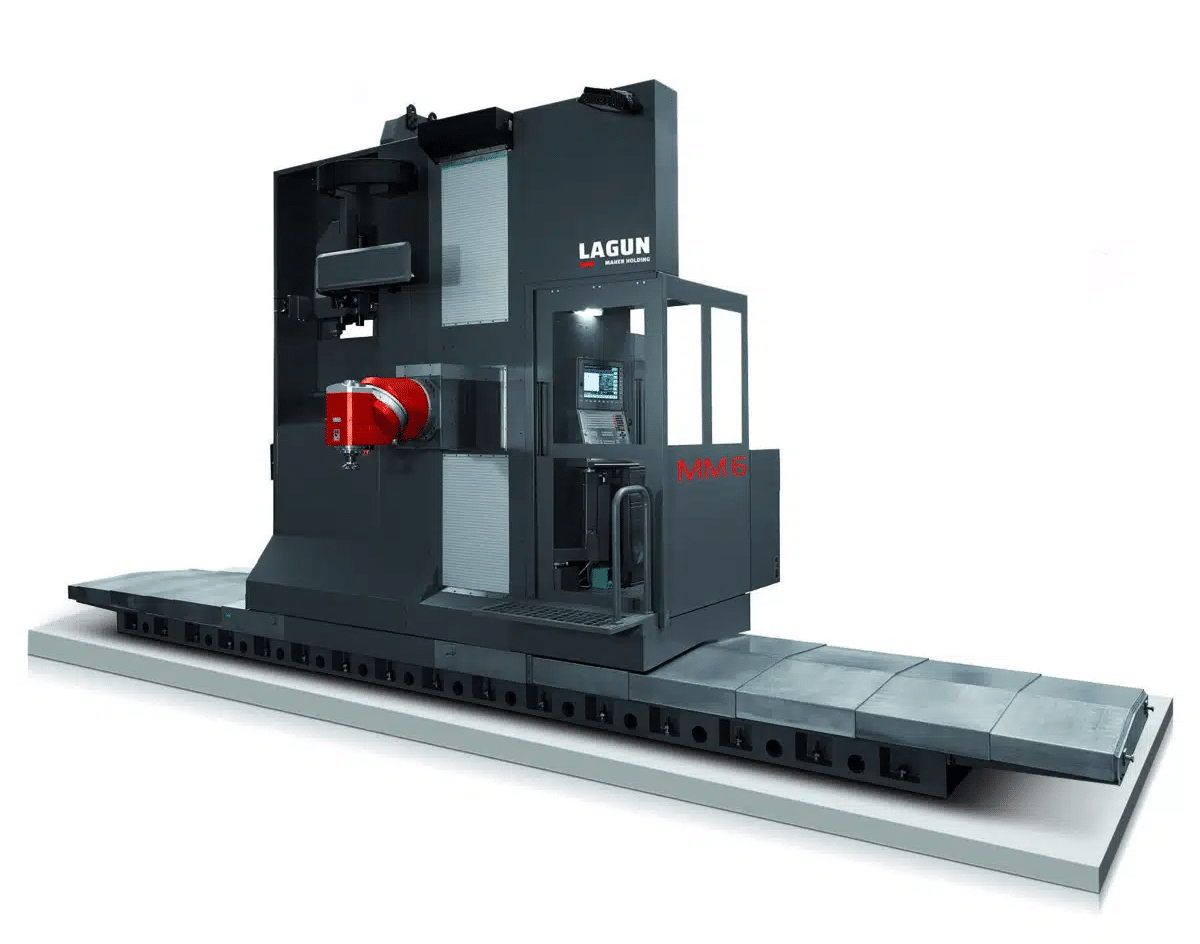

Lagun’s Traveling Column Milling Machines are designed for optimal performance with longitudinal movement of the column, head, and tool along the three linear machining axes. This innovative design allows for the machining of large and heavy parts without needing to move them, offering significant space savings. The column’s guidance on the bed-table ensures precision and stability. These machines are configured for pendular work across various areas, and can include versions with integrated rotary plates, providing versatile solutions for efficient and accurate milling operations.

Lagun’s Floor Type Milling Machines feature longitudinal movement of the column, head, and tool along a robust bed. This movement allows for multiple configurations for securing parts, providing exceptional versatility. The independent fixings and tables of the bed, combined with the “column-carriage-ram” assembly, enable the positioning of parts with varying shapes and dimensions. This design facilitates the creation of various machine types, making them ideal for diverse milling operations requiring flexibility and precision.

Lagun’s T-Type Milling Machines offer transverse movement of the column (V axis) parallel to the ram movement (Y axis) and feature a rotating table. This design allows for the turning of large parts and enables high-precision machining with the ram positioned close to the column. The innovative movement of the column ensures exceptional accuracy, making these machines perfect for complex and detailed milling tasks that demand precision and reliability.

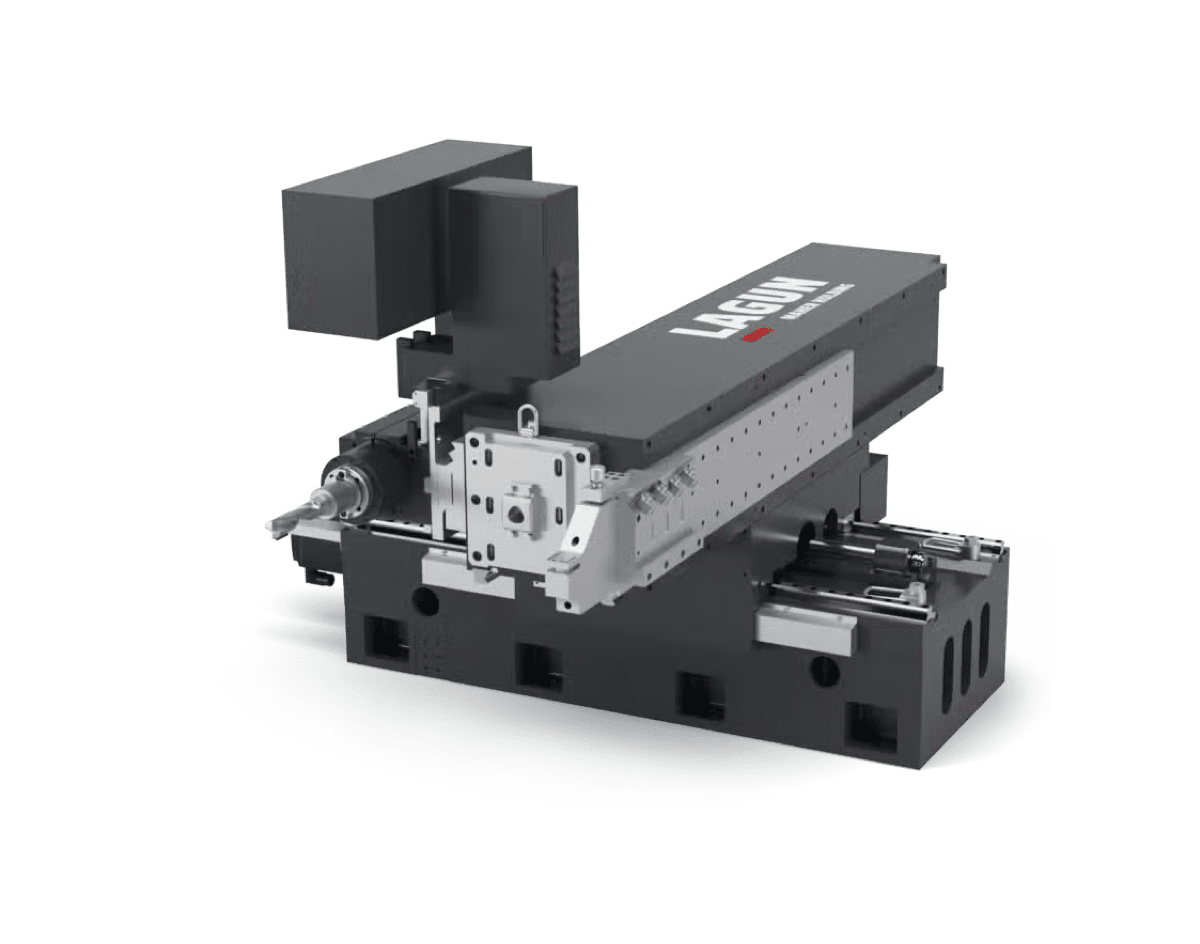

Our modular architecture allows systems to be built from interchangeable components, offering key benefits such as: Flexibility and scalability, Easy maintenance and repair, Interoperability between modules, Cost efficiency, Faster development cycles, Adaptability to future technologies, Fault isolation to minimize system impact, Reusability and sustainability

In summary, the modular design of LAGUN MACHINE TOOLS is ideal for developing complex, evolving systems across various fields, including software, hardware, and manufacturing.

Portable Milling bring the capabilities of a milling machine directly to the job site. They offer flexibility and convenience for on-site machining tasks, making them ideal for industries requiring in-situ operations. These machines are designed for portability without compromising precision and efficiency. Unlike traditional methods, where workpieces must be transported to a workshop, our mobile machines bring precision and efficiency directly to your site. This innovative approach drastically reduces downtime, slashes costs by eliminating transportation, and delivers high-quality results right where you need them. Perfect for demanding industries like shipbuilding and energy, our on-site machining solution is your go-to for seamless, cost-effective, and accurate machining in any environment.

Portable Milling Machines

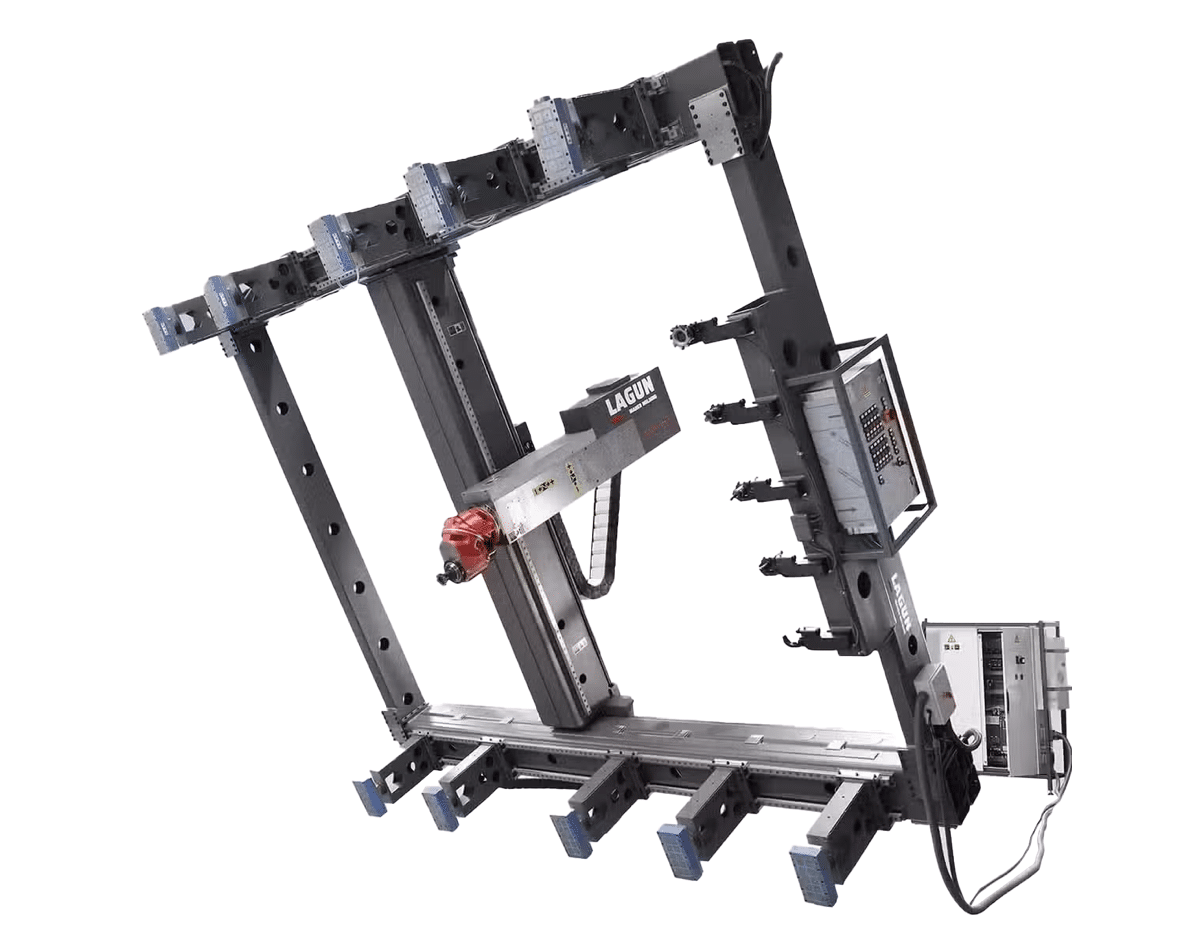

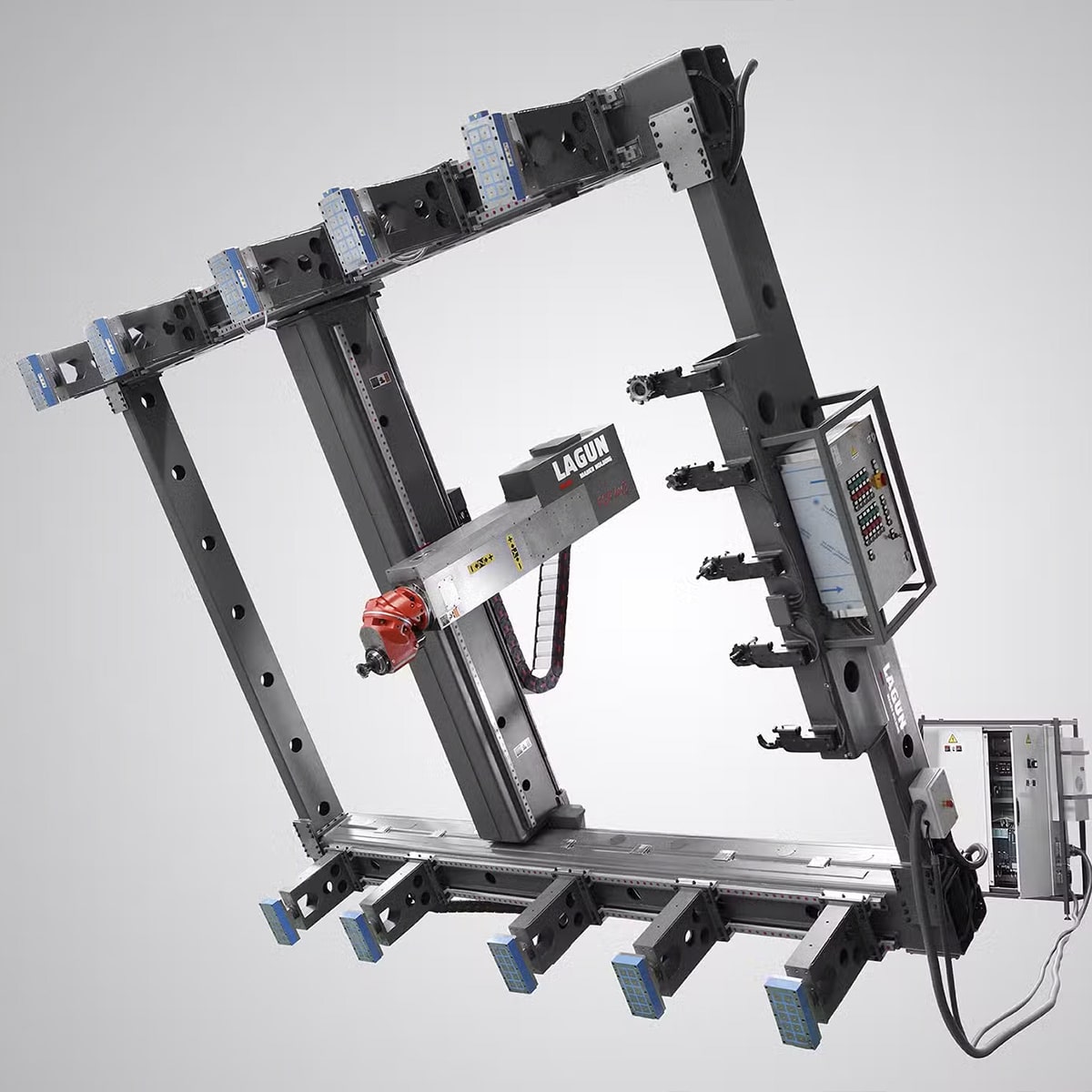

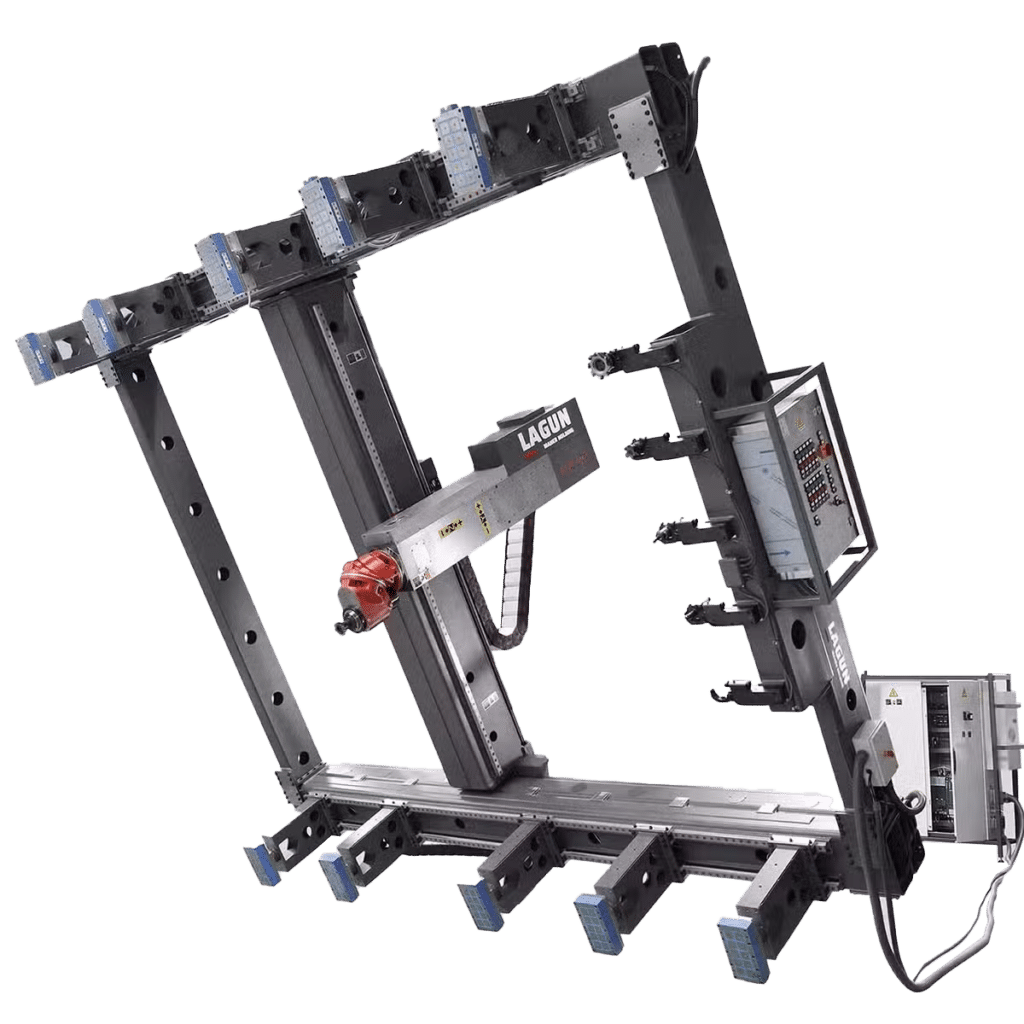

Lagun Mobile Gantry Machine

Introducing the FGP CNC Mobile Gantry Milling Machine, the game-changing machine ideal for onsite machining. This technology allows one to set up the machine around the workpiece. The FGP is capable of performing milling, drilling, tapping and boring operations. It can satisfy the highest quality standards, both in terms of geometric tolerances and surface finish.

Portable Milling Machines

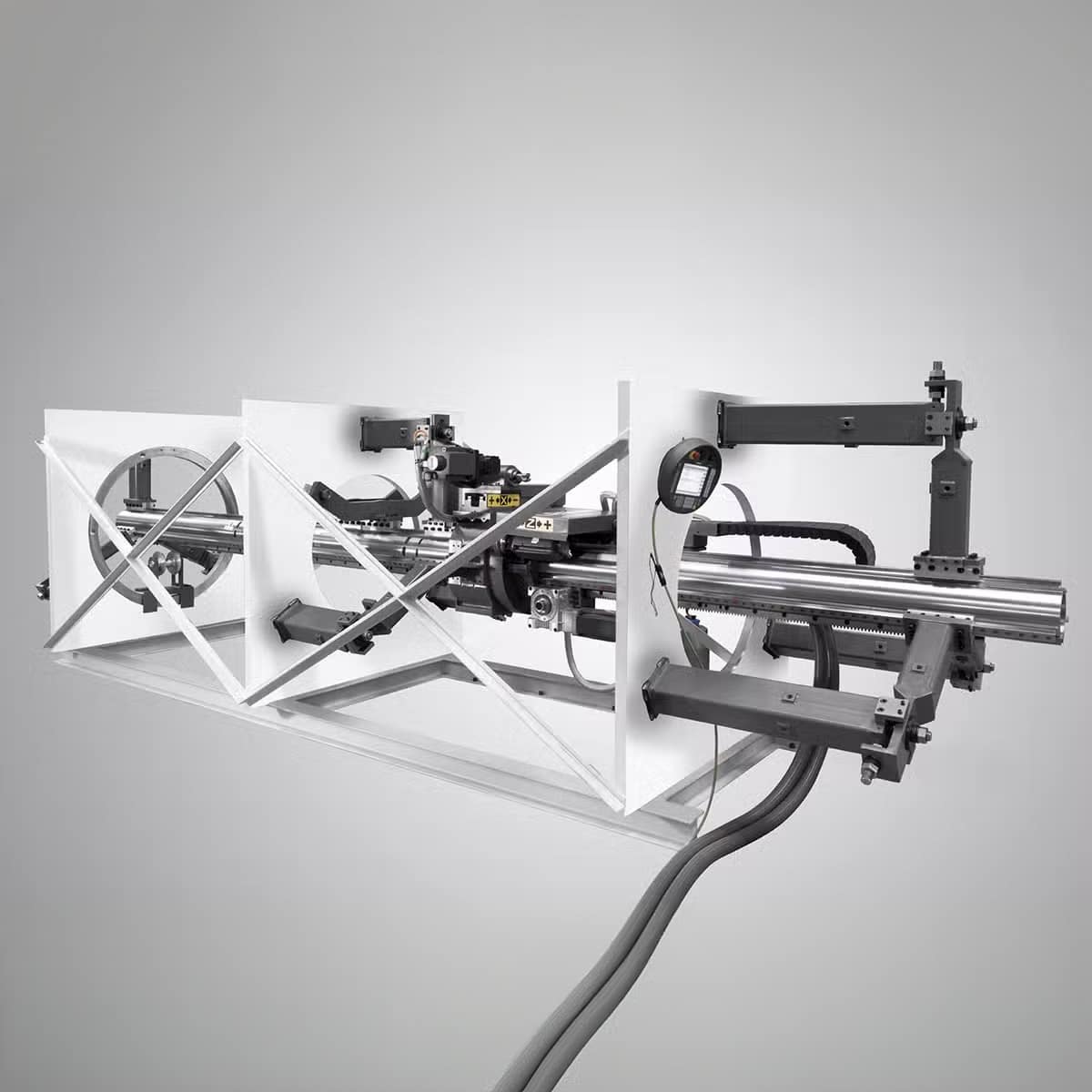

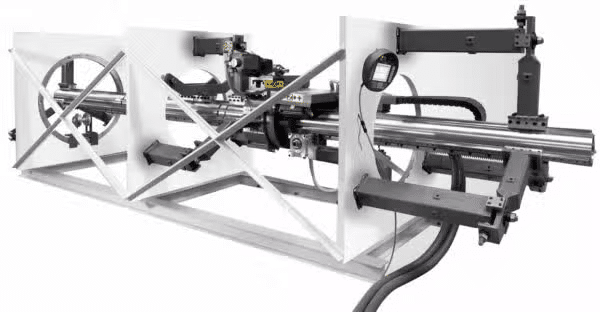

Lagun Mobile Line Boring Machine

Lagun’s Mobile Line Boring Machine has a modular design, making it the ideal solution for machine work in one’s manufacturing plant.

The user can assemble these uniquely designed machines through several steel vertical plates with openings, according to their specific needs. The machine can move through these openings performing several tasks (ie boring, milling, facing, drilling and tapping).

We provide a wide range of milling machines with different architectures

Our milling machines are designed and manufactured at our facilities, supervising the whole production process to guarantee a quality product.