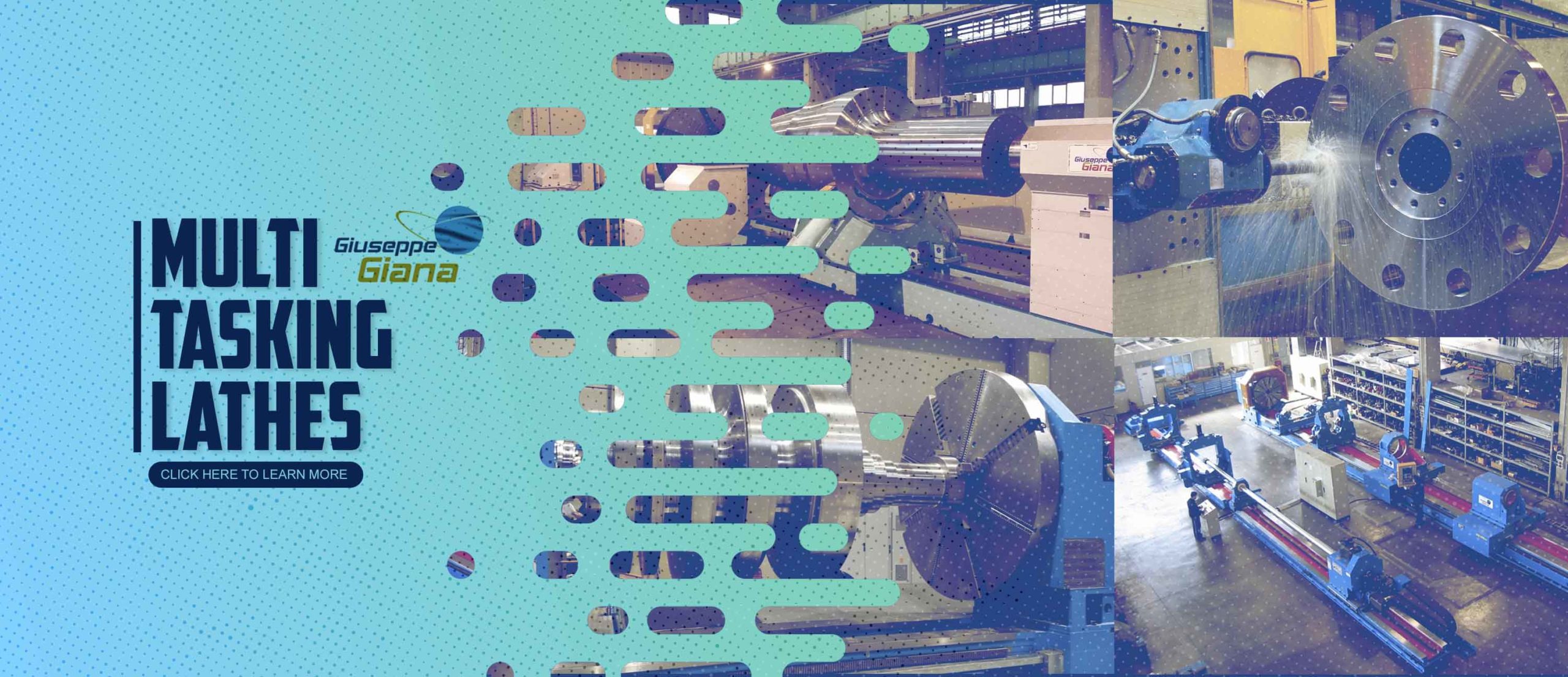

Giuseppe Giana's Multi-Tasking Lathes

As Giuseppe Gianna’s exclusive US distributer, we thought we’d start out the new year by highlighting their GG-TRONIC Multi-Tasking Lathes. This series of multitasking CNC lathes exemplifies Giana’s capability in engineering the most sophisticated lathes on the market and shows you that no job is too large for them to handle. Constructed with a highly customizable design, and ultra-rigid bodies, These lathes are precise and reliable. High-powered, the machines are particularly suitable for heavy-duty machining in the precision mechanics sector, for the machining of ship masts, wind turbine masts, turbine shafts, oil pipeline valves, crankshafts and rolls, large winch drums, etc.

Giana's Multi-Tasking Lathes

One of the GG-TRONIC’s main strengths is its multifunctionality. This series of machines come designed to be easily configured with several accessories. This allows the buyer to ”build” a machine that better suits their needs. The customer can choose from accessories like boring bar, steady rests, milling columns, tool changer devices, and so on. Additionally, there is an optional machine cover, for operating out of spaces that need more cleanliness and security. This machine range is engineered with the goal of proposing a highly customizable multitasking turning center which meets customer’s demands while maintaining that same reliability exhibited by all of Giuseppe Giana’s products.

GG-TRONIC Key Features

The new line of GG-TRONIC turning and milling centers can machine cylinders and complex components up to 157 in. (4000mm) in diameter and 984 in. (25,000mm) in length. Machining processes for these parts can take several hours. Additionally they could potentially utilize several types of machining. To achieve a quicker machining process, reaching traverse speeds of 787in/min is possible. The machine structure, built entirely of cast iron, is even strong enough to hold anti-vibration boring bars suitable for internal boring to a depth of over 197 in. (5000mm).

Among the key design requirements taken into account (including the machine’s ergonomic features such as ease of clamping, tool visibility during machining and access for measurements after machining), both machining precision and frame rigidity are crucial. Giana achieves both through a unique technological concept. To ensure the best performance Giuseppe Giana decided to implement a TwinDRIVE rack-and-pinion system from Redex Andantex. This turnkey system benefits from innovative features that deliver outstanding performance. Exceptional positioning precision and repeatability, together with overall stiffness is achieved as a result of this.

The TwinDRIVE rack-and-pinion drive systems consist of two parallel-mounted planetary servo reducers that come coupled electrically. This preloaded system eliminates backlash and contributes to higher precision. An integrated output pinion shaft supported by reinforced output bearings provides extreme rigidity in all directions.

Models

Two styles of multitasking lathes are available in this series. The single bed, GG-TRONIC 800-1000 is an affordable, and compactly designed lathe in comparison with Giana’s other models. Giana designs these lathes to contain the same advantages of a machine with four guides. It’s stable structure means it’s able to address customers most rigorous demands, making it the ideal lathe for the Oil & Gas sectors. In addition to the single bed model, Giuseppe Giana designs a Double Bed Multitasking lathe. These easily configured machines have several accessories, allowing you, as a buyer, to “build” a machine. You can supply it with a boring bar, steady rests, a milling column, a tool changer device, and so on. This machine range is engineered with the goal of proposing a multitasking turning center, highly customizable to meet customer’s demands while maintaining that same reliability exhibited by all of Giuseppe Giana’s products.

About Giuseppe Giana

With over 40 years of knowledge and constantly evolving facilities, workflow and technology, it’s easy to understand why Guiseppe Giana’s known as artisans of their craft. Founded in 1964, Giuseppe Giana SPA specializes in constructing CNC turning machines with 4-bed guideways and CNC deep hole drilling and boring machines. The company uses its large pool of advanced machine tools for contract machining and the production of components new machines. Giuseppe Giana Spa makes grinding machines, boring machines, milling machines, and milling and planing machines, including one of Europe’s largest grinder for flat surfaces. The passion and precision Giana brings to every machine has allowed them to grow their company from their homeland in Italy to countries like India, USA, Brazil, Denmark, France, Russia, Germany, Israel, Turkey, exc.