Lagun Maher Holding showcases new heads at EMO exhibition

At last week’s EMO exhibition Lagun Maher Holding, a Lagun partner, showcased a new series of precision milling heads at the 2021 EMO Milan exhibition. The trade show, which took place from October 4-9 in Milan, Italy, included hundreds of exhibitors from over 30 countries all exhibiting their latest and greatest products and technologies.

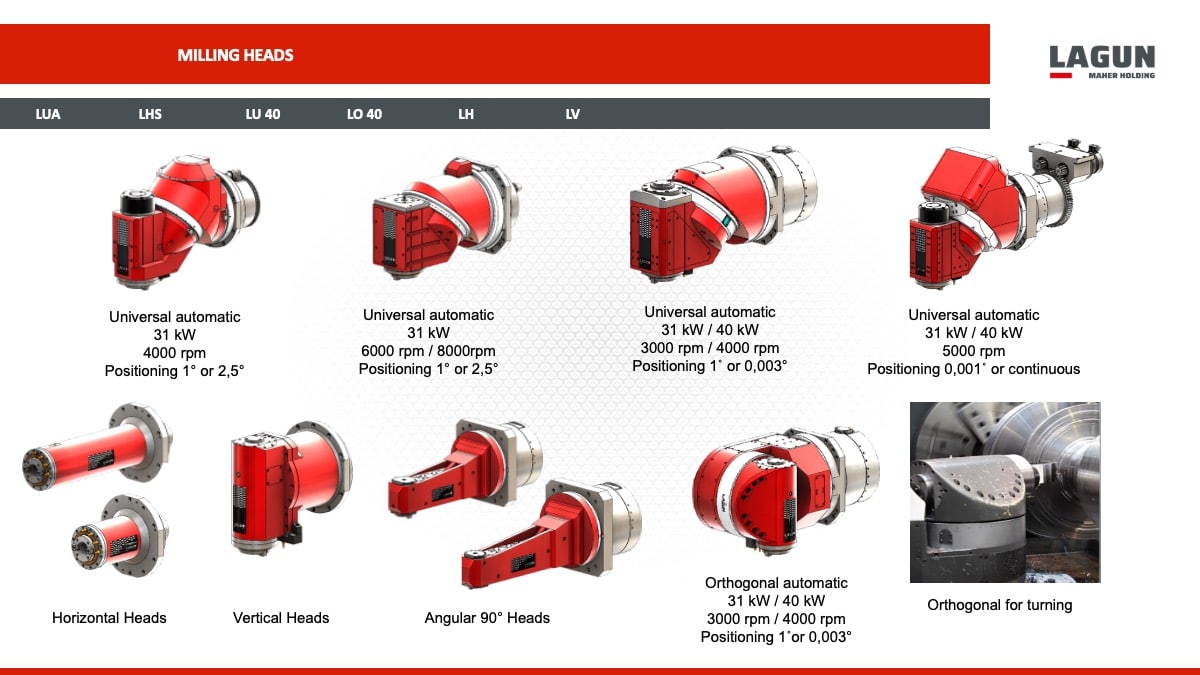

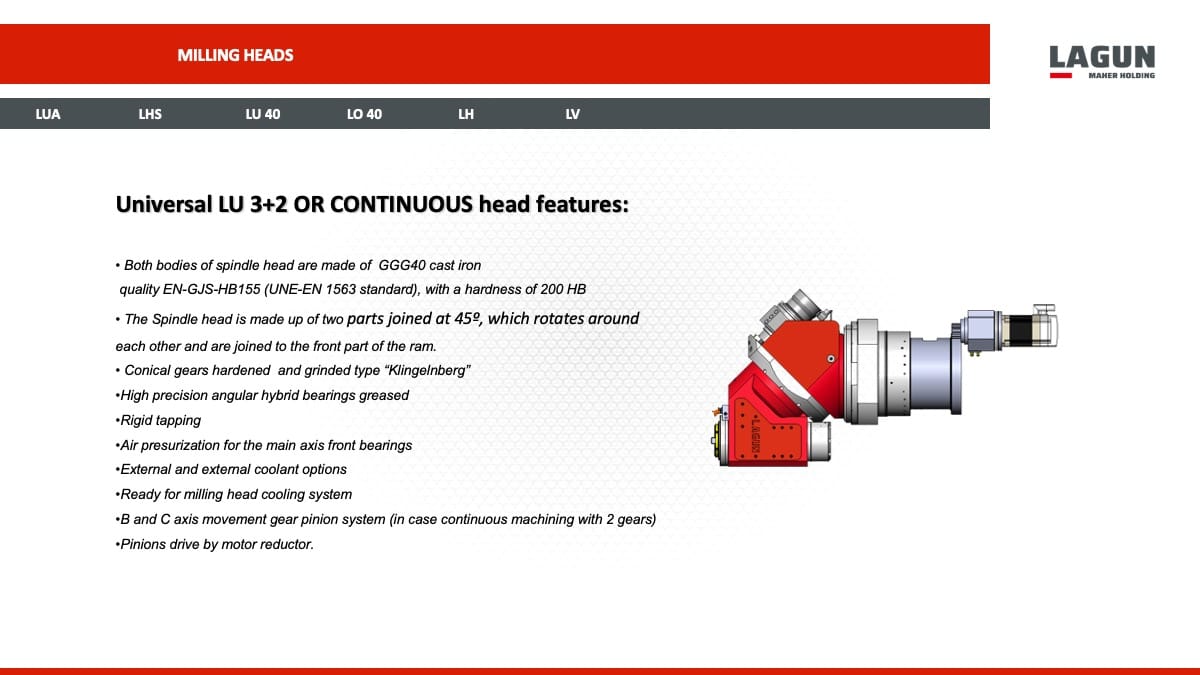

In their continuous pursuit of innovation and advancement in the machining industry, Lagun Maher Holding proudly released their LU-S and LU-C motorized milling heads. The LU-S features simultaneous positioning every .001° while the LU-C incorporates continuous rotation of both bodies and positioning every .001°. In addition, both bodies of the all LU-series spindle heads are made of GGG40 cast iron quality EN-GJS-HB155 (UNE-EN 1563 standard), with a hardness of 200 HB, ensuring consistently precise performance over the long life of the head.

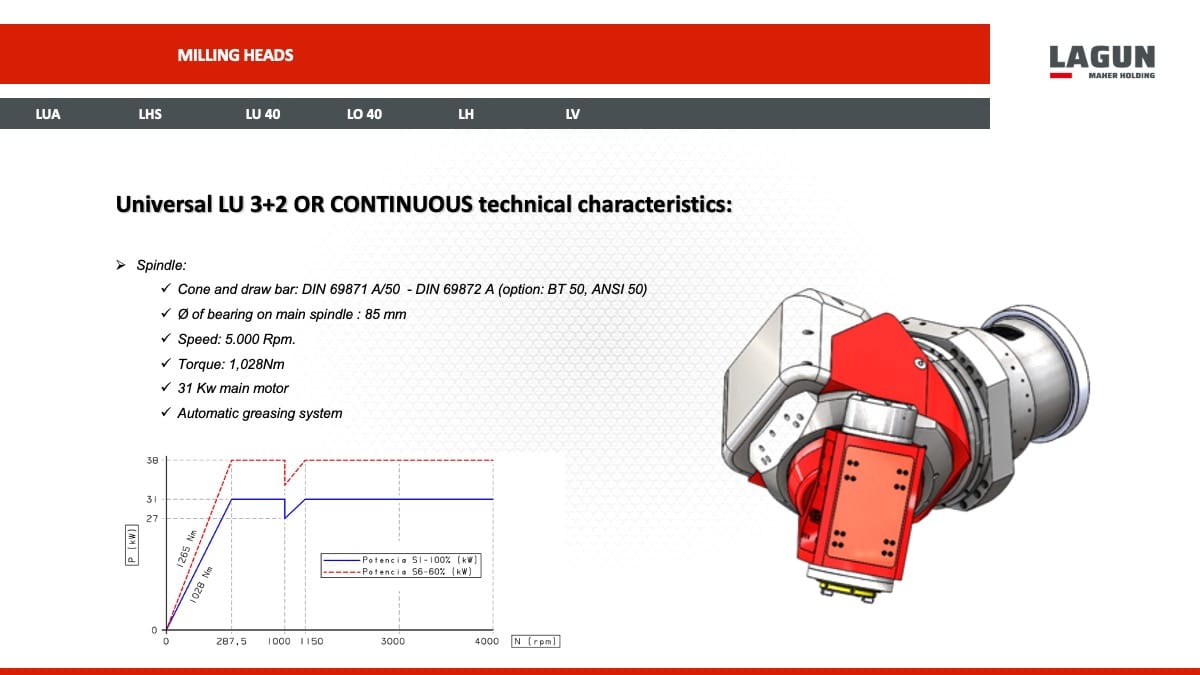

The spindle head also features “Klingelnberg” type hardened and ground conical gears, greased high-precision angular hybrid bearings, rigid tapping, internal/external coolant options, a B and C axis movement gear pinion system for continuous machining with 2 gears and more.

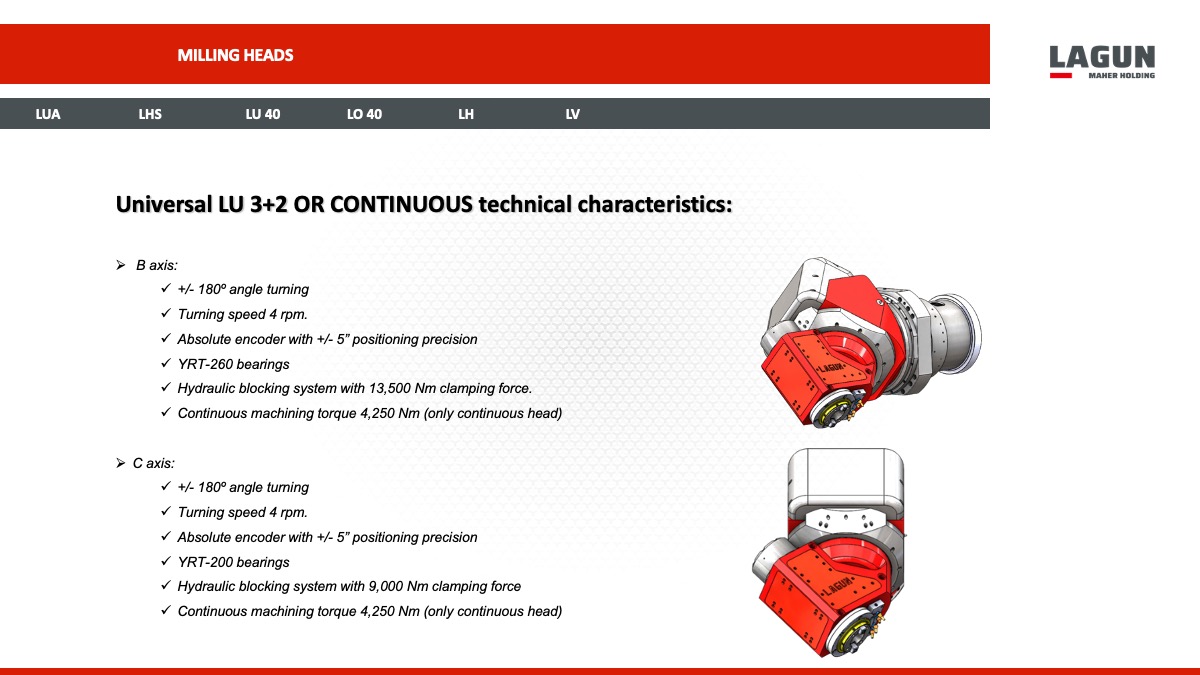

The B-axis includes +/- 180° angle turning, 4 RPM turning, an absolute encoder with +/- 5” positioning precision, YRT-260 bearings, a hydraulic blocking system with 9957.09 ft-lbs (13,500 Nm) clamping force and a continuous machining torque of 3134.64 ft-lbs (4,250 Nm) (continuous head only).

The C-axis also includes the same +/- 180° angle turning, 4 RPM turning, continuous machining torque and absolute encoder with +/-5” positioning precision and clamping force. But, the C-axis differs slightly from the B with its YRT-200 bearings, hydraulic blocking system with 6638.06 ft-lbs (9,000 Nm).

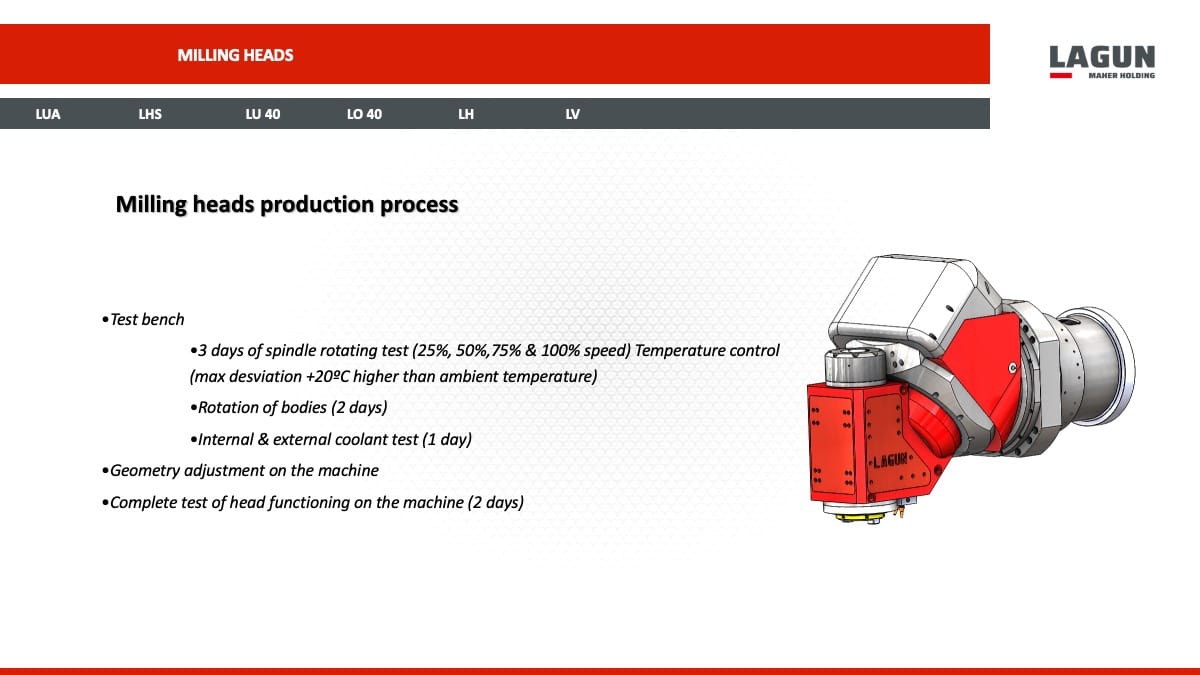

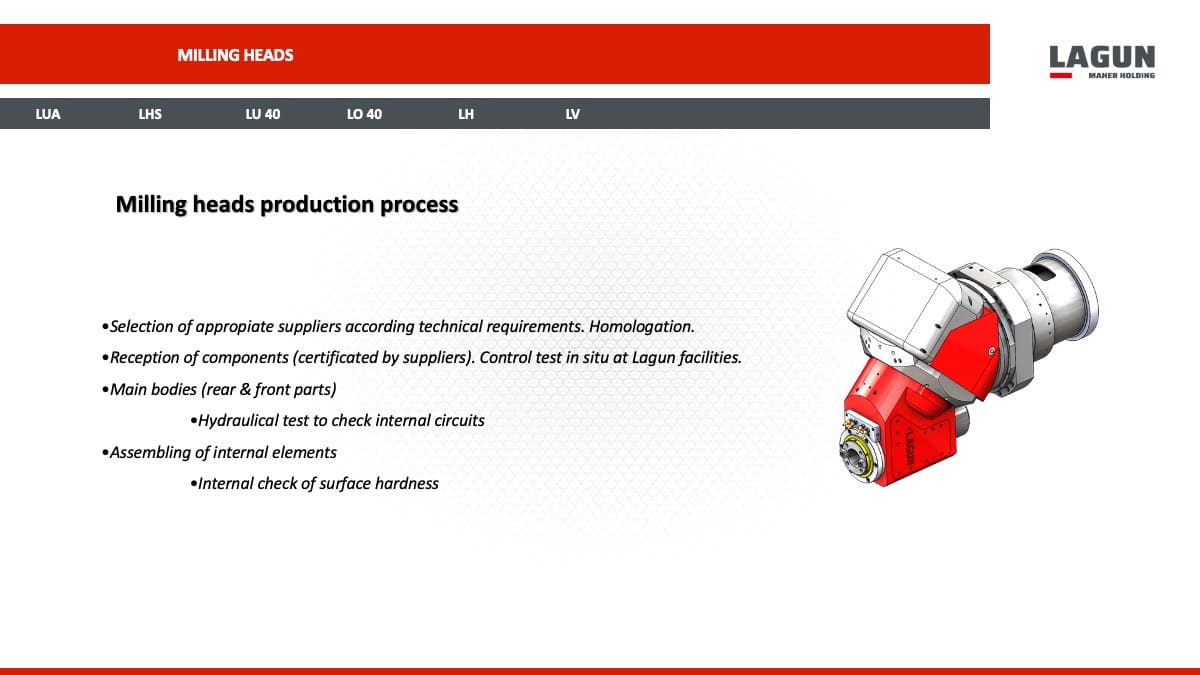

To consistently manufacture these high-quality and precise heads, Lagun Maher Holding enforces the most stringent production and quality control standards at their facilities. Each head spends 5 days on the test bench, with 3 days of spindle rotating tests at 25%, 50%, 75% and 100% speed in addition to temperature control tests (max deviation +68°F (20°C) higher than ambient temperature.) Then, the rotation of all bodies is tested for 2 days before the internal and external coolant is tested for 1 final day at the test bench. After a geometric adjustment on the machine, each head undergoes a complete on-machine test for 2 full days before being certified and shipped off.