OC SAN X LAGUN

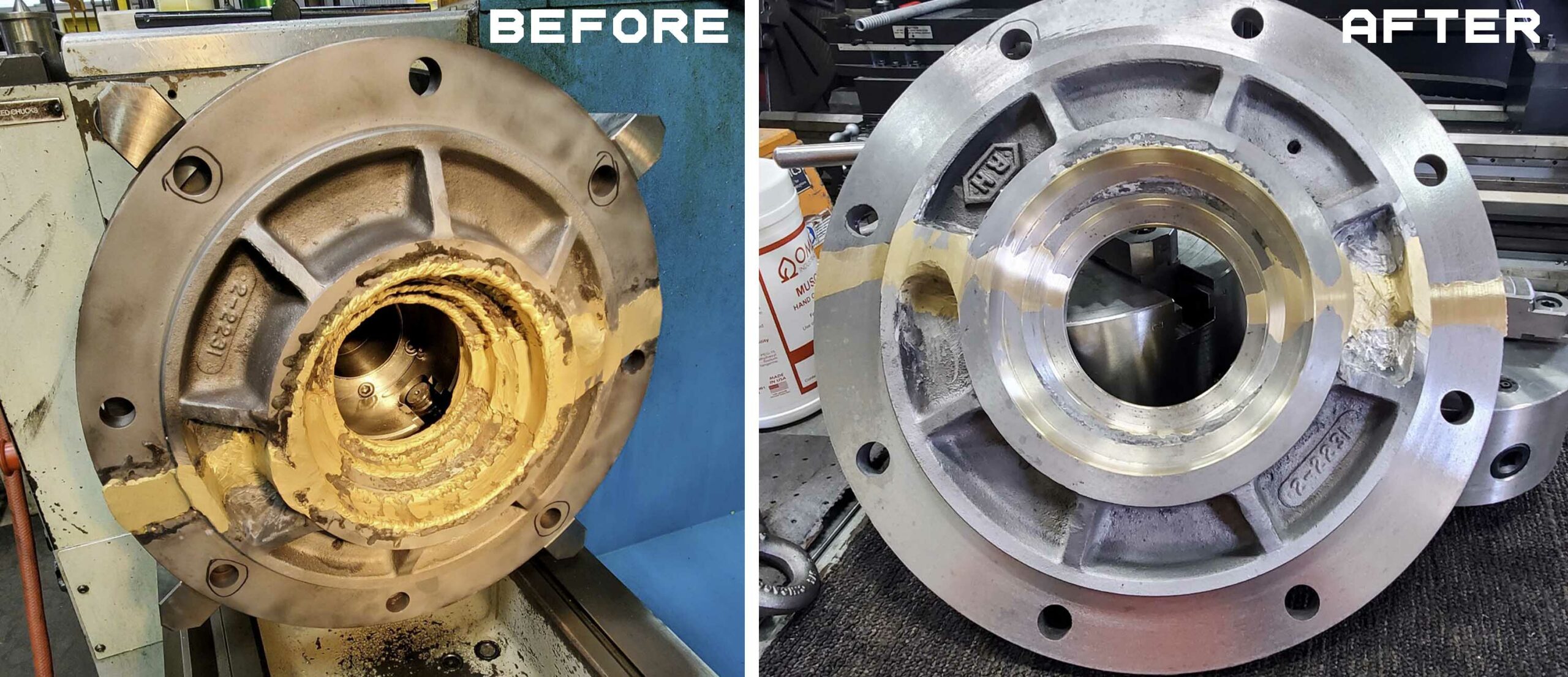

During a recent visit to the OC Sanitation District we met with machinist Luis Kawile to hear about his first-hand experience with our Power One Lathe. Luis has worked with OC San for just over 20 years where he regularly uses our Power One lathe for machining and manufacturing parts. “We’re like the red cross at OC San,” says Luis. “Everybody comes to us for help.”

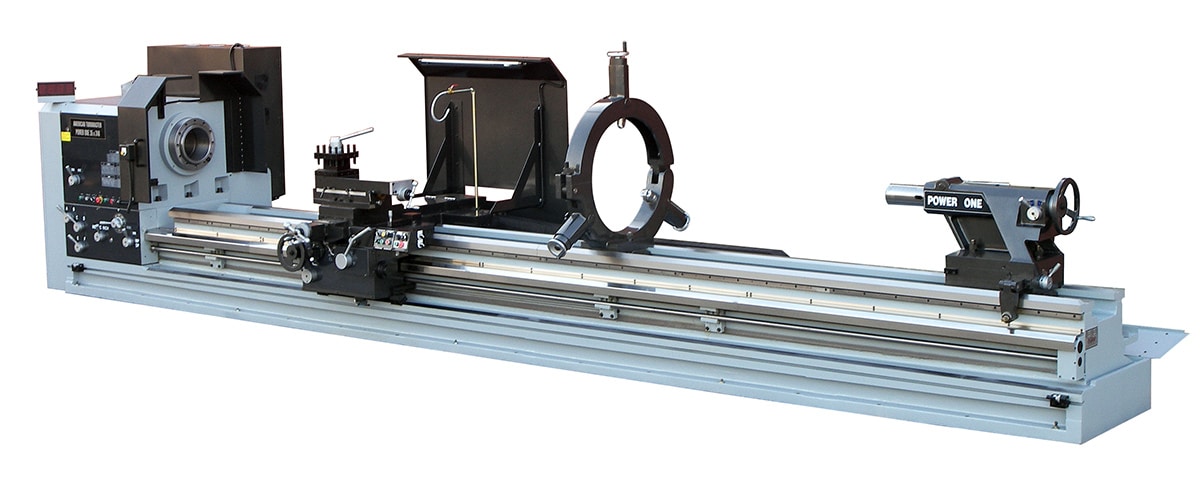

Because of their reliance on Luis and his team, having a dependable and accurate machine is essential for OC San. It’s for this reason that they purchased a Lagun Power One Lathe. The rugged body of these lathes come built on a one piece, or monolithic, bed. In addition to this, the cross-slide ways and leadscrews come hardened and ground. This design is what makes our power lathes stable machines with the ability to maintain tight tolerances and accuracies.

Why A Lagun Power Lathe?

“We wanted a bigger machine that would fit all our pump parts. Lagun [Power One] was the best lathe I could find,” Luis informed us. With its 6” to 24” bore size range, the power series is perfectly suited for turning workpieces like the parts Luis and his team regularly machine. In addition to its large bore size options, our power series is designed to support heavy workpieces without the need for additional support. For example, using only its standard tailstock, the Power One can hold an unsupported workpiece up to 11,000 pounds.

“[The Power One Lathe] has better quality, and it’s pretty simple to operate,” continued Luis. “The last job that I made here was three feet in diameter, I had to drill a hole. I used the tailstock to drill it, and that thing was so light. You don’t feel it!” Keeping usability and safety in mind, we’ve incorporated a specially designed tailstock for this series. Clamping is vital to properly secure a lathes tailstock when supporting heavy parts. This is an important step for both the operator’s safety and for achieving accurate finishes. Because of this we incorporate locking mechanisms under the ways tailstock body clamps (vertical lock mechanism) and a lateral tailstock body clamp.

Lagun’s Power Series are truly the ideal lathe for heavy duty boring and turning. With its numerous safety and user-friendly features, working with these hefty lathes is a simple and enjoyable process. “There’s nothing that compares to Lagun,” claims Luis.

To learn more about our Power Series Lathes, please contact our expert team of sales reps. For smooth and accurate, heavy duty turning, no one does it better than Lagun.

LAGUN’S POWER SERIES

The American Turnmaster Power Series is Lagun’s solution to large spindle bore engine lathes. This comprehensive series features seven models with swings ranging from 35” to 120”. Lagun designs these powerful machines to easily accommodate large diameter turning and threading applications.

Lathes Model: Power One Power Five Power 5 TL 45 Power 5 TL 50 Power 5.5 Pwr 7-120x295S Pwr 7-120x295L

Swing Over Bed 35″ / 40″ / 45″ / 50″ 45″ / 50″ / 60″ / 70″ 45″ 50″ 60″ / 71″ / 80″ 120″ 120″

Swing Over Carriage 33″ 39.43″ 43″ / 53″ / 63″

Swing Over Cross Slide 24″ / 29″ / 34″ / 39.76″ 32″ / 37″ / 47″ / 57″ 106.29″ 94.48″

Distance Between Centers 60″ – 472″ 60″ – 800″ 80″ 80″ 60″ – 480″ 295.27″ 295.27″

Spindle Speed RPM Range 7-1,000RPM / Varies Size 7 – 700RPM / Varies Sizes 7-700 RPM 6-480 RPM 3-300 RPM 2-150 RPM 2-150 RPM

Hole Through Spindle 6.02″ – 16.14″ 6.02″ + 6″ 9″ 9″ (Opt up to 32″) 9.055″ 9.055″

Spindle Nose A2-11 to A2-28 A2-11 A2-11 A2-15 A2-15 A2-20 A2-20

Motor HP 30HP (40HP Opt) 30HP (40HP Opt) 30HP 30HP 50HP (Opt 60HP & 75HP) 100HP 100HP

Disk Clutch Headstock No No No No No No No

3 V Ways Yes Yes Yes Yes Yes No (4 Way) No (4 Way)

Inch Thread Range (TPI) 1/2 to 28 1/2 to 28 1/2 to 28 1/2 to 28 1/2 to 28 1/2 to 28 1/2 to 28

Metric Thread Range 1-56mm 1-56mm 1-56mm 1-56mm 1-56mm 1-56mm 1-56mm

Work Piece Capacities: 26,790 lbs 32,683 lbs 66,138 lbs (w/out Steady) 66,138 lbs (w/out Steady)

Digital Threading Control? No No No No No No No

CNC or Manual Manual Manual Manual Manual Manual Manual Manual

WHAT ARE BIG BORE LATHES?

Big bore lathes, also known as oil country lathes, are a type of heavy-duty horizontal machine specially engineered to handle the processing of large-scale tubing and piping. Although these lathes are primarily used by the oil field industry, their applications have grown throughout the years. Now a days you’ll find big bore lathes in the aerospace, agriculture, printing, timber, and mining industries. In fact, these lathes are suited for any industry requiring large diameter turning and threading.

Enjoyed this post? Make sure you sign up for our newsletter to get the latest Lagun Blog Posts. And follow us on all our social media, like Instagram, Facebook, and YouTube, to stay up to date with all things Lagun.