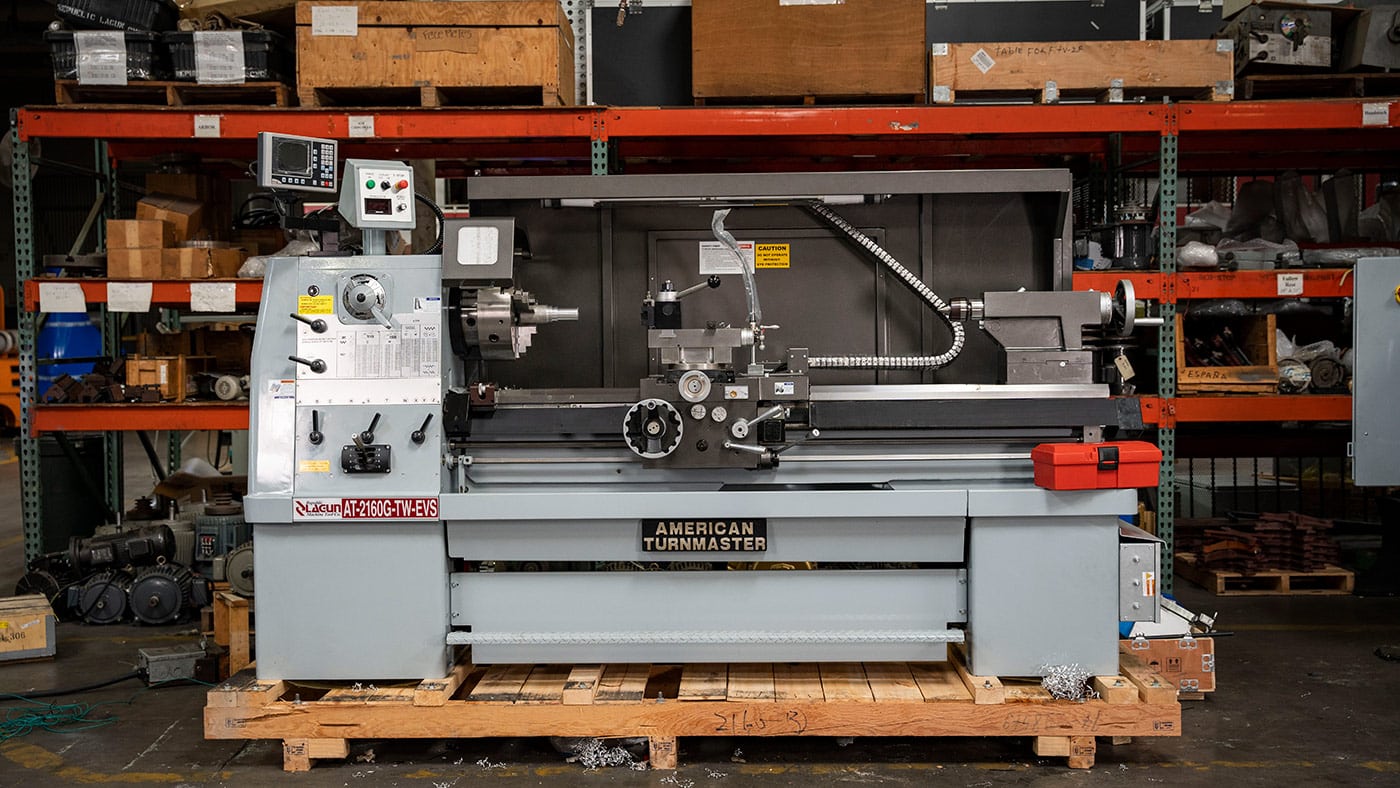

Lagun's AT-2160-G-TW EVS Toolroom Lathe

We’re kicking off the new year with a look at our AT-2160-G-TW EVS from our classic line of American Turnmaster Lathes. These reliable machines come with a 21” swing, with the option of downsizing to 18”. The AT-21 lathe has a center distance range of 40” – 120”, with a hefty 3” spindle bore. The outstanding features incorporated in the AT-2160 make it the ideal tool room lathe.

Outstanding Features

Each machine comes equipped with a heavy-duty headstock, constructed with hardened and “Reishauer”-ground gears and shafts that drive the lathes spindles for reliable steadiness. The dynamically balanced forged alloy steel spindle has a 16-step speed range with 20 to 1,600 RPM capability.

Ultra Stable Body

These lathes come with our signature American Turnmaster design of 3-V Way Beds for added stability. This unique design eliminates reversal error when turning long shaft O.D.’s. This ensures perfect alignment during any job. Furthermore the specially designed bed ways are made of hardened and ground alloy steel. This setup creates a wear resistant barrier around the bed, making it easy to maintain and clean.

EVS OPTION

All our manual machines have the option of receiving a full EVS conversion. When converted to EVS, the operator can adjust the lathes speed with a simple dial. We equip all our EVS machines with an RPM readout, allowing the operator to easily view the changing RPM’s. This feature also makes it simpler to fine tune cutting speed. Additionally, the conversion means the machine provides full HP to all RPM’s. This decreases energy consumption by delivering speed levels as needed, rather than consistently. Furthermore, by assuring it runs at a desired speed, the EVS head avoids disturbing material during processing.

IN HOUSE ELECTRICS

We’re proud to say all elements of our EVS conversion are done in-house at our California based warehouse. First our skilled electricians remove all the old wiring from the lathes’ electrical panel. Next, they meticulously replace each component with our own electrics. By doing this you can feel confident knowing we’ve assembled your machine using local parts. This means in the event a replacement is needed, you can easily obtain the part by reaching out to us. As an added bonus, by doing the eclectics in house our electricians can ensure your machine is UL Certified, or meets any other required standards, such as Canadian electric standards, per your request.

“A SERIES” OPTION

Along with the optional EVS conversion, we also offer the “A” series version of our lathes. The A series is the “Made In USA” version of our machines. From all electrical components, down to push buttons, our team retrofits each A series machines with American made parts at our Los Angeles based warehouse. The rigorous and precise work, along with the convenience of using high-quality, locally sourced components will add great value to your machine.

Enjoyed this post? Make sure you sign up for our newsletter to get the latest Lagun Blog Posts. And follow us on all our social media, like Instagram, Facebook, and YouTube, to stay up to date with all things Lagun.