Machine Spotlight: Lagun's TM & TM T

We’re back with the next instalment of our Lagun Maher Holding spotlight series. As we move down the line of Lagun’s exceptional Machining Centers, this week we’ll focus on the TM & TM T series.

The TM & TM T

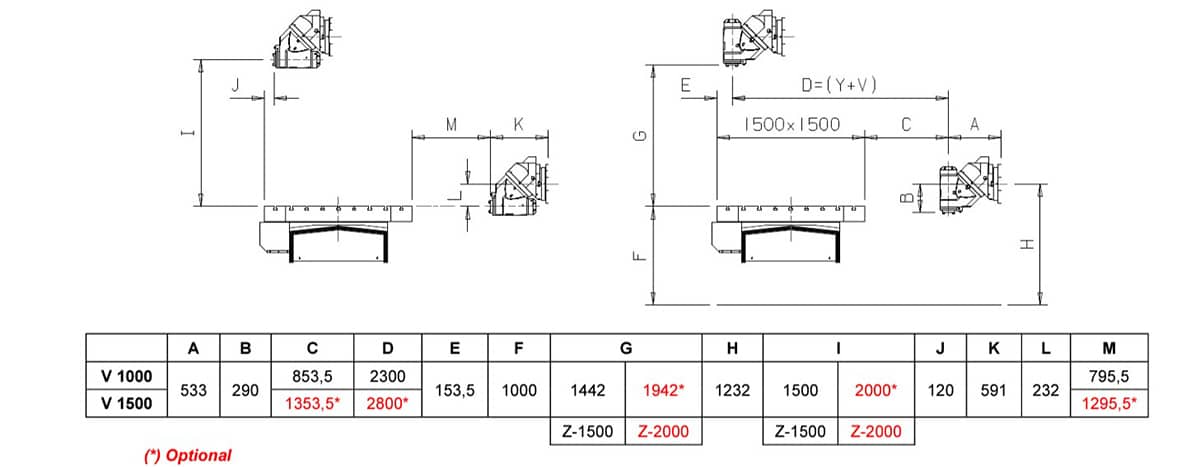

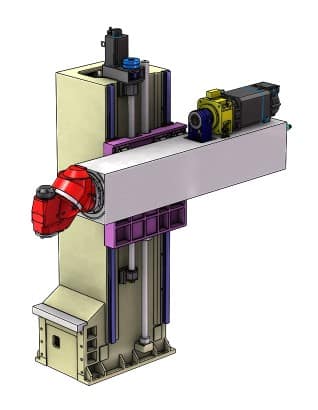

The TM is a cross moving milling machines capable of multi axis machining. Lagun created this line of machines as their sophisticated solution for machining 5-sided workpieces. This ability enables the machine to work with a wide variety of shapes and surfaces, and where material obstructs access.

The TM T is a multi-process variant of the TM. It is intended to perform both milling and turning with a few simple reconfigurations of the machines parts. Thus the user saves both time and resources by reducing the need for large fixture changes. These machines are ideal for machining large bulky parts with high precision requirements. Users can achieve this by setting several relatively short travels. When combined this secures optimum precision, as well as the ability to work with bulky pieces with high loads on a robust and precise table

Exceptional Features

Lagun’s Compact Draw

Lagun’s modular configuration (Compact Draw) is utilized in the manufacturing of the TM & TM T, meaning all models in this spectacular line have interchangeable slides, rams and columns. This design method endows each machine with enhanced rigidity, precision and ergonomic working comfort for the operator.

Additional TM & TM T Features

In addition to being designed with Lagun’s Compact Draw system, these cross moving milling machines come with several outstanding features. Each model includes a specific tool clamping system, such as HSK 100T or Capto C8, for milling and turning. Also included is the LO40 head, an Orthogonal head with Hirth System, for locking the main spindle. The versatile tool positioning of this head endows the machine with the ability to achieve external turning of different profiles.

To ensure the longevity of the machine, the highest care and detail was given in the design of chip and coolant removal. For instance, channels are placed around the entire bed perimeter with a full enclosure, double built-in chip extractor with easy access to the machine and perfect visibility of the working area.

Furthermore, the sturdy, oversized mill bed comes with reinforced ribbing, fortifying its stability during heavy milling. The hardy table, column, slide and ram systems come designed with roller/shoes that exceed manufacturing requirements. Designed to be as close to the column as possible, the ram placement ensures a sturdy column-slide-ram assembly. This results in a rigid and light slide for vertical movement.