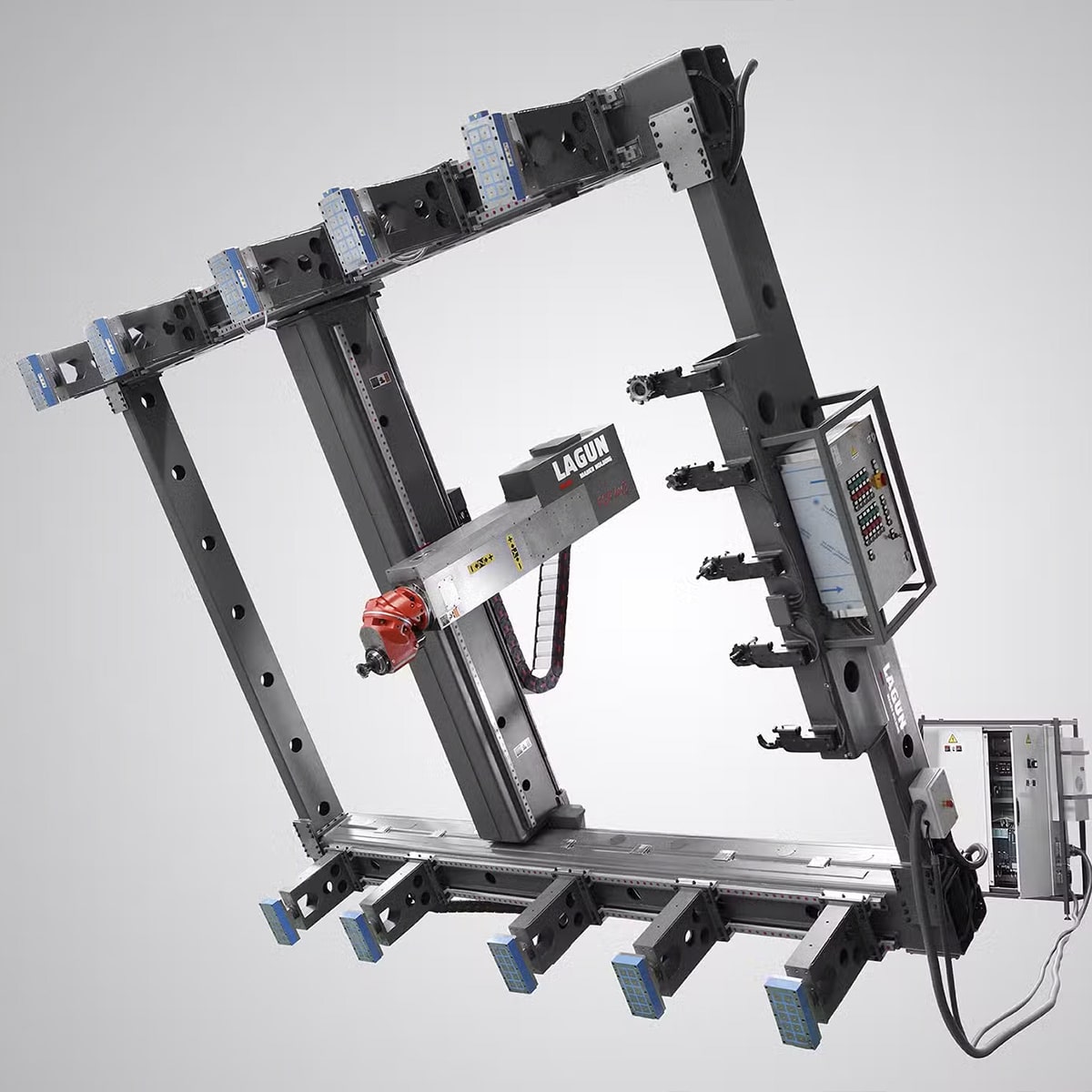

Lagun Mobile Gantry Machine FGP

OUTSTANDING FEATURES

Specifically used in the

• Defense Industry

• Shipbuilding

• Heavy Construction & Fabrication

• Power Generation & Turbines

• Large Valve Manufacturers

DESCRIPTION

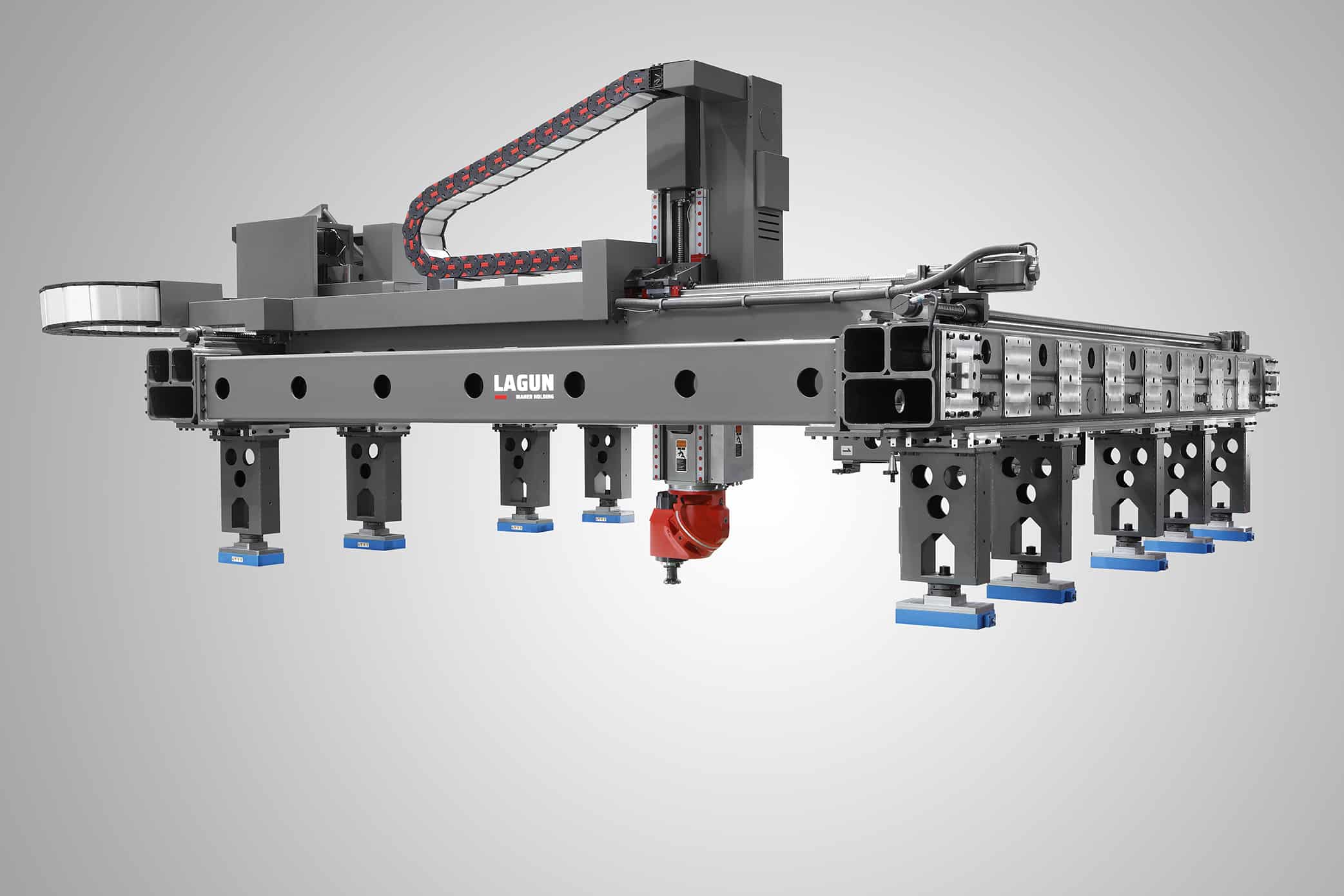

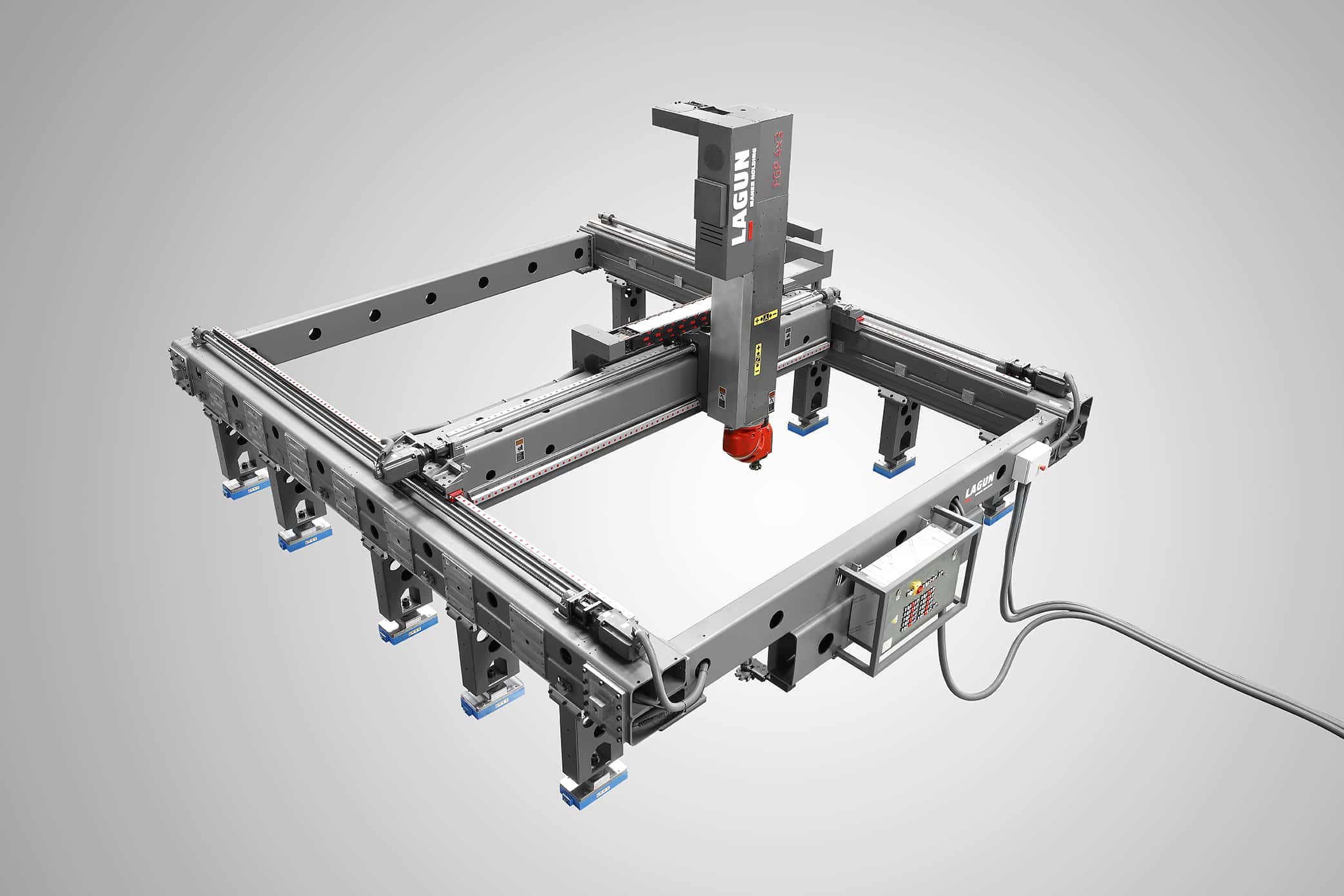

Introducing the FGP CNC Mobile Gantry Milling Machine, the game-changing machine ideal for onsite machining. This technology allows one to set up the machine around the workpiece. The FGP is capable of performing milling, drilling, tapping and boring operations. It can satisfy the highest quality standards, both in terms of geometric tolerances and surface finish.

What is on-site machining?

On-site machining is technology radically different from the typical method of machining. Traditional machining calls for the workpiece to be moved to the location of the machine. However, on-site machining method allows the machine to be moved around the workpiece. Mobile machines are moved to the part, eliminating the need to transport the part to a machining workshop and back. This saves the user both time and resources. By using mobile machines, high quality and accuracy machining can be achieved on site.

Advantages:

-Time and effort savings: shorten downtime by machining the workpiece in its original assembly area.

-Cost savings: reducing transportation costs ultimately achieves significant economic savings.

-Accessibility savings: on-site machining enables the user to machine workpieces unable to be transported offsite.

It is the ideal machine for shipbuilding, energy- turbine housing, turbine split lines, generator corset, machining pump and motor pads.

For additional information regarding this machine and the special solutions it can provide, contact a Lagun Expert. See additional Lagun Heavy Mills machines here.

SPECIFICATIONS

| MODEL | FGP 43 | FGP 22 |

|---|---|---|

| Traverse X | 157 .48" (4000 mm) | 78.74" (2000 mm) |

| TraverseY | 118.11" (3000 mm) | 78. 74" (2000 mm) |

| Traverse Z | 39.37" (1000 mm) | 19.69" (500 mm) |

| S Spindle head 1 | ||

| • Power | 13.41 HP (10 KW) | 13.41 HP (10 KW) |

| • Spindle taper | 150 so | 150 so |

| • Speed range | 3000 RPM | 3000 RPM |

| MODEL | FGP 43 | FGP 22 |

|---|---|---|

| Traverse X | 157 .48″ (4000 mm) | 78.74″ (2000 mm) |

| TraverseY | 118.11″ (3000 mm) | 78. 74″ (2000 mm) |

| Traverse Z | 39.37″ (1000 mm) | 19.69″ (500 mm) |

| S Spindle head 1 | ||

| • Power | 13.41 HP (10 KW) | 13.41 HP (10 KW) |

| • Spindle taper | 150 so | 150 so |

| • Speed range | 3000 RPM | 3000 RPM |

| MODEL | FGP 43 | FGP 22 |

|---|---|---|

| Traverse X | 157 .48″ (4000 mm) | 78.74″ (2000 mm) |

| TraverseY | 118.11″ (3000 mm) | 78. 74″ (2000 mm) |

| Traverse Z | 39.37″ (1000 mm) | 19.69″ (500 mm) |

| S Spindle head 1 | ||

| • Power | 13.41 HP (10 KW) | 13.41 HP (10 KW) |

| • Spindle taper | 150 so | 150 so |

| • Speed range | 3000 RPM | 3000 RPM |

* All Product Specs are Subject to Change at Any Time

One year or 2,000 hours from date of installation, (single shifting) whichever occurs first. For parts and service contact our support team at:

or call

800.421.2105

*Applies to domestic sales only.