Bringing Precision to Your Project: Lagun’s FGP and MFP Portable Machining Solutions

In the oil and gas industry, where the scale of equipment and the breadth of operations are vast, the challenges of traditional machining can be significant. Lagun’s FGP CNC Gantry Milling Machine and MFP-350 Line Boring, Milling, and Turning Machine redefine these challenges by bringing portable, world-class machining capabilities directly to the operational site. This innovative approach not only streamlines the process but also significantly reduces the costs and logistical complexities associated with transporting large parts for offsite machining.

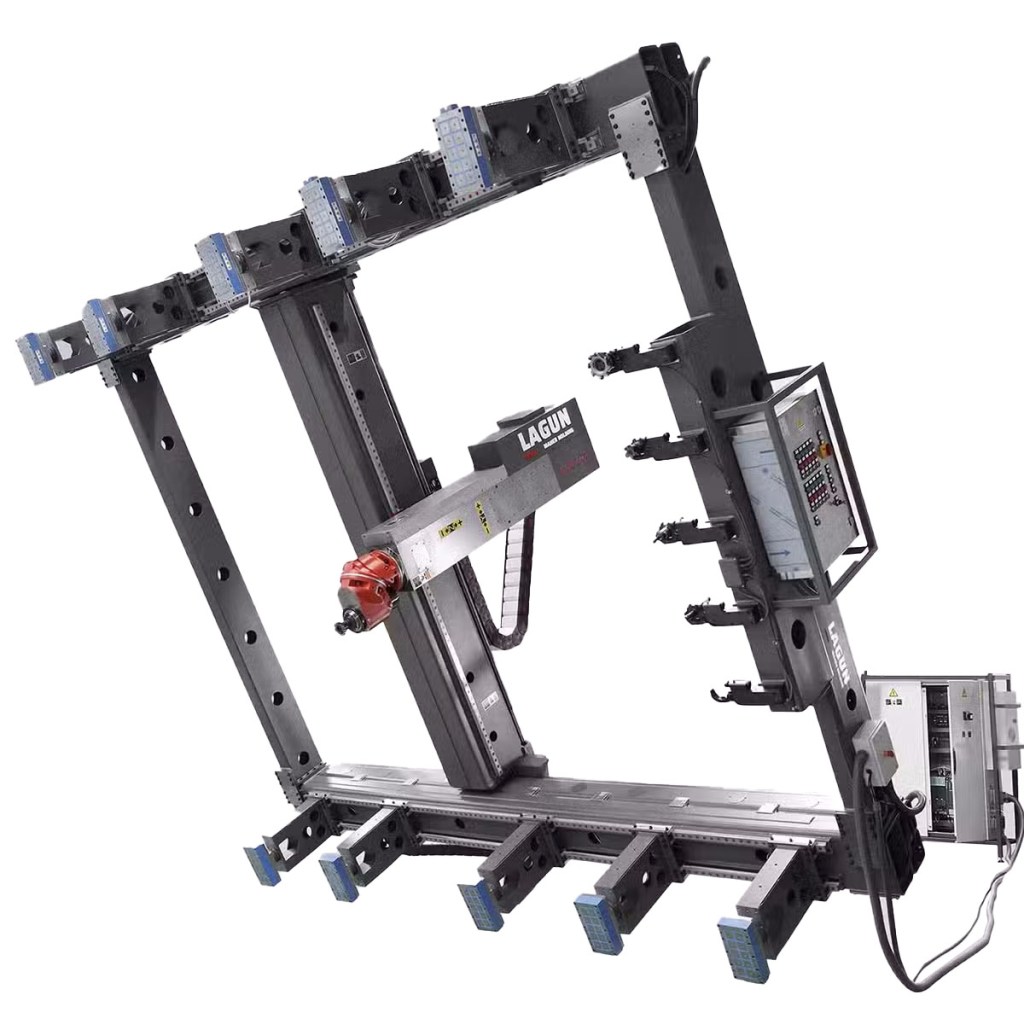

FGP CNC Gantry Milling Machine: Precision Where You Need It

Designed, assembled, and tested in Los Angeles, CA, the FGP CNC Gantry Milling Machine is engineered for exceptional performance in demanding environments like those found in the oil and gas sector. This machine excels in executing precise milling, drilling, tapping, and boring operations right where the workpiece is located. It’s specially tailored for handling large components such as turbine housings, generator corsets, and large valves, which are prevalent in power generation and turbine maintenance.

Key features of the FGP include:

- Portability: The design allows for the setup of the machine directly around large components, mitigating the need for their transportation.

- High Precision: Meets stringent quality standards for geometric tolerances and surface finish, ensuring top-notch machining.

- Adaptability: Although perfect for the oil and gas industry, the FGP’s versatility makes it suitable for defense, shipbuilding, and heavy construction.

MFP-350 Line Boring, Milling, and Turning Machine: Complex Machining Made Portable

The MFP-350 distinguishes itself with a versatile modular design that enables it to perform multiple machining tasks—including milling, boring, facing, turning, drilling, and tapping—all within a single setup. This CNC portable machine is adept at maneuvering through and machining structures that are already assembled and difficult to relocate due to their size or integration into complex installations.

Advantages for the oil and gas industry:

- Comprehensive Machining: Capable of creating large bore diameters and precise machining of assembled infrastructure directly on-site.

- Flexible Configuration: Its modular design allows for the machine to be disassembled into manageable pieces, facilitating transportation and setup in remote or confined spaces typical in oil fields.

- Enhanced Efficiency: By facilitating in-place machining, the MFP-350 significantly reduces the downtime associated with traditional disassembly, transport, and reassembly processes.

Precision in Place—Portable Machining That Moves With You

Lagun Engineering’s portable machining solutions, the FGP and MFP-350, are revolutionizing how work is done in the oil and gas industry. They offer a potent combination of flexibility, precision, and efficiency, crucial for maintaining the continuous operation of energy production facilities and minimizing operational disruptions.

For industry operators seeking to enhance their on-site capabilities while cutting down on logistical expenditures and downtime, Lagun’s FGP and MFP-350 machines provide an innovative solution. They ensure that high-quality, precise machining is always just where you need it—right on-site. Embrace the change with Lagun’s portable machining; contact Lagun Engineering today to see how these machines can be integrated into your operations for unparalleled operational flexibility and productivity.