Unleashing the Power: Lagun Engineering’s Power Series Lathes for the Oil and Gas Industry

The oil and gas sector demands equipment that meets the highest standards of reliability, precision, and durability. Lagun Engineering’s Power Series American Turnmaster Heavy Duty Engine Lathes embody these qualities, making them an ideal choice for the industry’s strenuous needs. This blog takes a closer look at the distinctive features and capabilities of the Power Series models One, Five, Six, and Seven, highlighting why they stand out as superior tools for oil and gas operations.

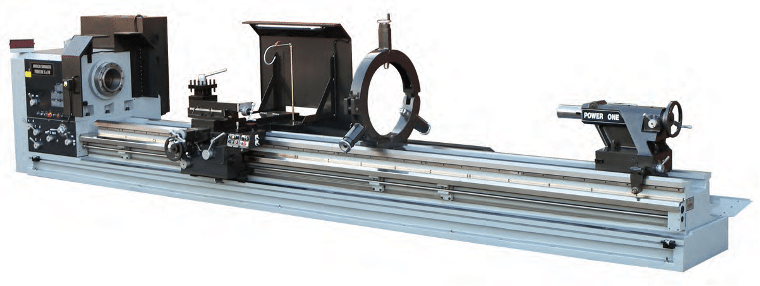

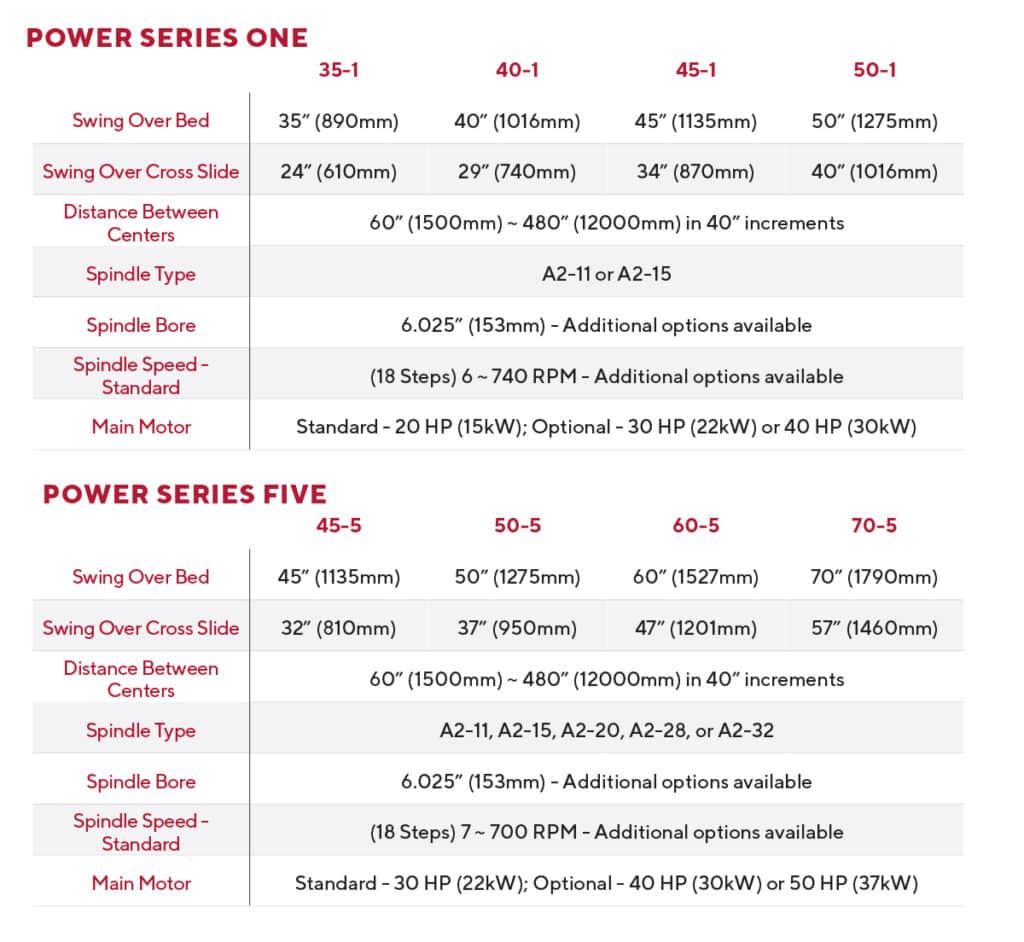

Power Series One and Five:

Lagun Engineering’s Power Series One and Five lathes represent the pinnacle of precision engineering, designed to meet the rigorous demands of the oil and gas industry. These models are built on a solid foundation with a one-piece, monolithic bed floor type casting that ensures stability and reduces vibration during intensive operations. The combination of advanced design features and robust construction makes these lathes ideal for a variety of machining tasks where precision and reliability are paramount.

- One piece (monolithic) bed, floor type casting

- Three bedway design with extra way supporting the apron

- All ways are hardened and ground

- Forged steel spindle with opposed taper roller bearings (6” Bore)

- Hardened and ground gears, shafts, cross slide ways and screw

- Electromagnetic spindle brake

- Totally enclosed universal inch / metric gear box

- 18 speed geared headstock / 2 speed tailstock quill (Manual)

- 6-way rapid traverse and power feed to top slide

- Thread chasing dial

- Overload safety device on apron

- Dual voltage motor and controls, 20 to 50 HP

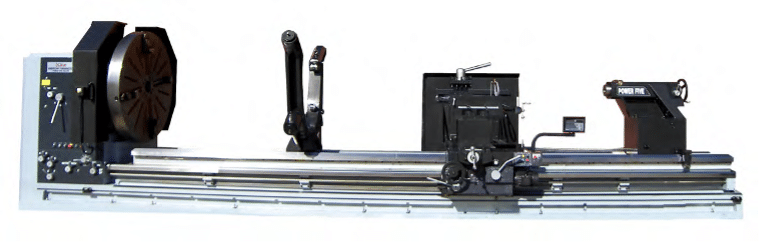

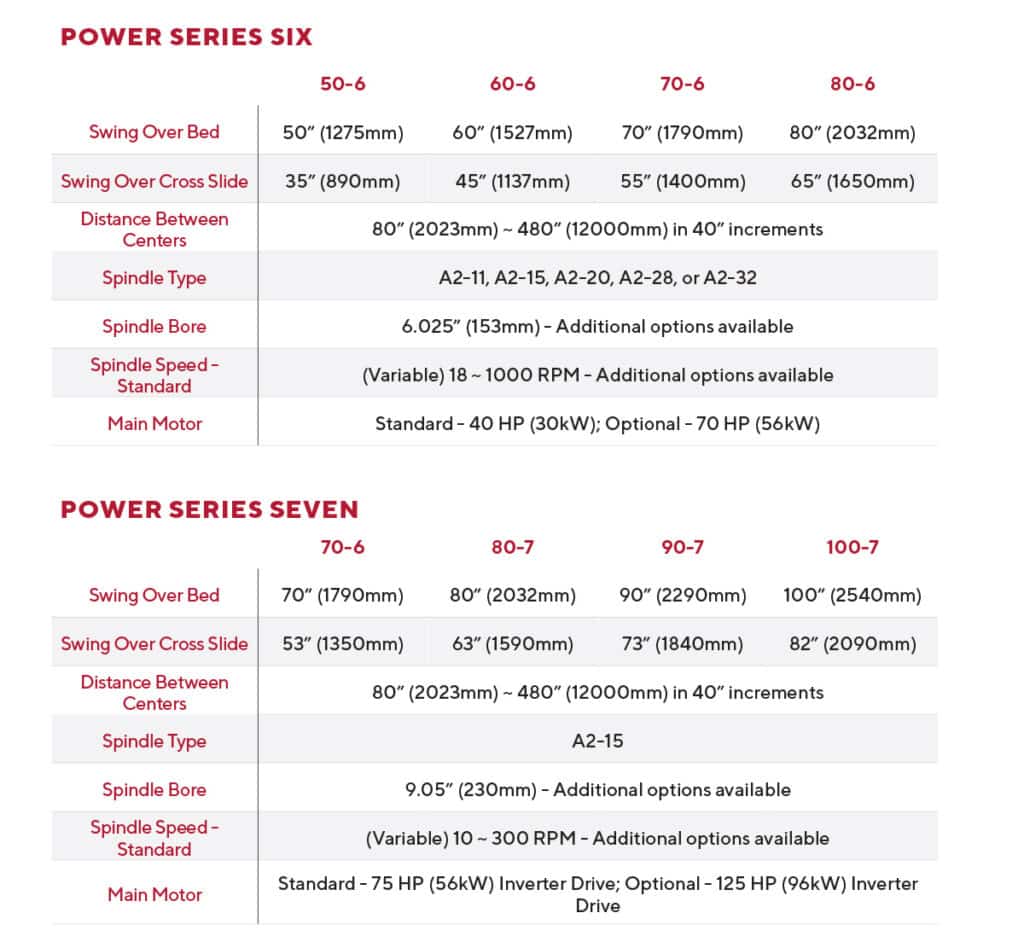

Power Series Six and Seven:

The Power Series Six and Seven lathes take performance to the next level with their massive one-piece floor type beds and superior Meehanite G-50 castings, designed for maximum rigidity and vibration absorption. These models are tailored for handling extremely heavy and large-scale workpieces typical in the oil and gas sector, featuring advanced lubrication, powerful tailstock capabilities, and variable spindle speeds to accommodate a wide range of material types and machining operations.

- Massive one piece floor type bed and base (no pedestals) for maximum rigidity and vibration absorption

- Highest quality Meehanite G-50 castings

- 4 shear bed with dual way center guide plus front lateral way for carriage support under heavy cutting

- Automatic lubrication throughout

- Massive power tailstock with built-in rotary (live) center; Movement of body on bedways and quill travel controlled by hydraulics

- A2-15 American Standard spindle nose with 9” (230mm) spindle bore is standard on Power Seven models; 6” (153mm) on Power Six models

- Variable spindle speeds in 4 automatic ranges through pneumatic shifting,

10 ~ 300 RPM - Hardened and precision ground headstock gears

- 6-way rapid traverse and geared power feed to top slide

- Carriage mounted pendant controls, and pendant controls for tailstock

Lagun Engineering’s Power Series Lathes offer the oil and gas industry machines that are not only equipped to handle the toughest materials but are also designed to deliver precision and longevity in harsh environments. The combination of advanced engineering, robust construction, and operator-focused features makes these lathes a pivotal asset for any operation looking to enhance efficiency and reliability. Whether you are drilling, threading, or undertaking complex part machining, the Power Series ensures you have the right tools to maintain high productivity and operational excellence.