Product Insights: All About the Chuck

If there’s one thing we know at Lagun, its knowledge is power. With this in mind, we’re launching a new blog series centered on educating you, our loyal customer, on the different parts and accessories Lagun has to offer. When you work with Lagun, we aim to help you make informed decisions. After all, the more you know, the better we’ll assist you! To start off this series, we’re deconstructing an essential machine tool accessory, the chuck.

What is a Chuck?

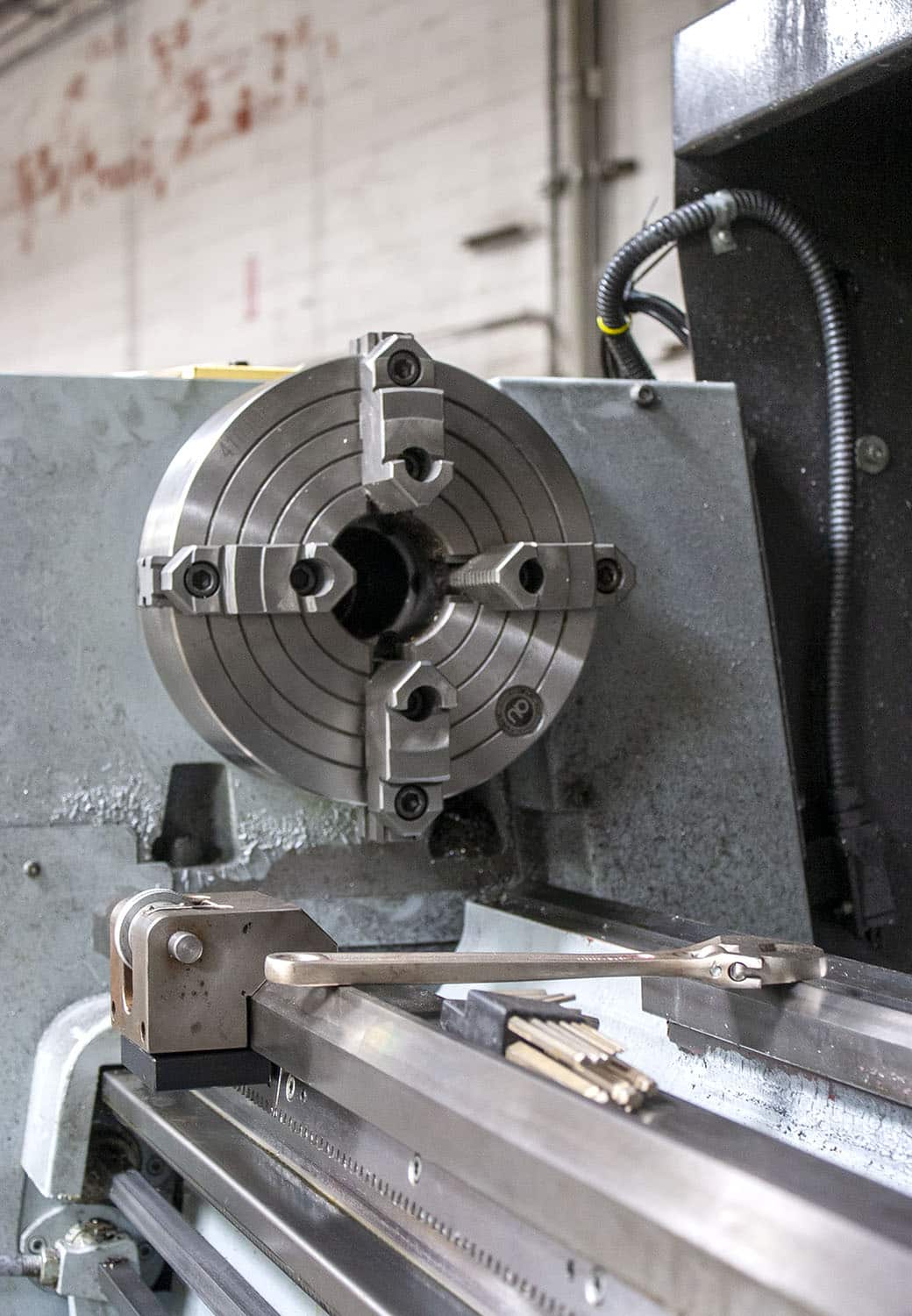

A chuck is a device used on machine tools to lock tools or parts into place. You’ll typically find this device mounted to a spindle, sitting over the machine’s ways. A second chuck cand be mounted to your machine, depending on your needs. For instance, if the workpiece being turned goes through the spindle, we can attach a second chuck inside the left end of the spindle, for added support.

Chucks come in various sizes and have four main types; all other chuck types are variations of these. In today’s post we’re exploring these chuck types. These types are the 4-jaw independent, 3 or 6-jaw scroll, 4-jaw combination, and drill chucks.

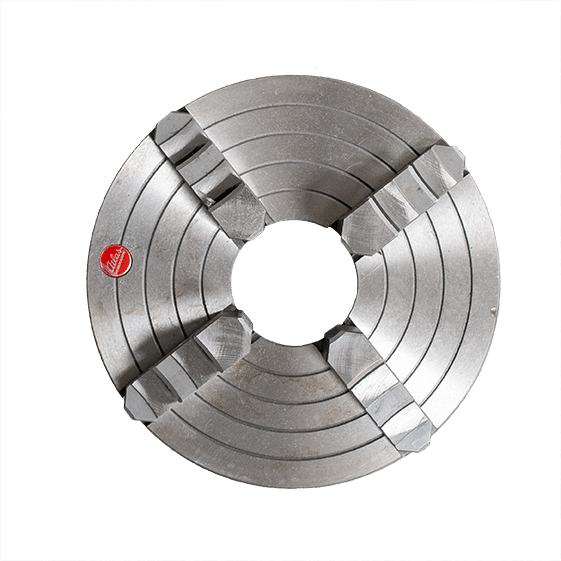

4-Jaw Independent Chuck

The most cost-efficient chuck, these come equipped with 4 independently moving jaws. By using either 2 or 4 of its jaws, this type can clamp square, rectangular, round, and irregularly shaped materials. If needed, the jaws on these chucks are reversible. This enables the chuck to hold a part inside or outside the spindle. However, using this kind of chuck can be a slow grind as each jaw must be individually manipulated into place.

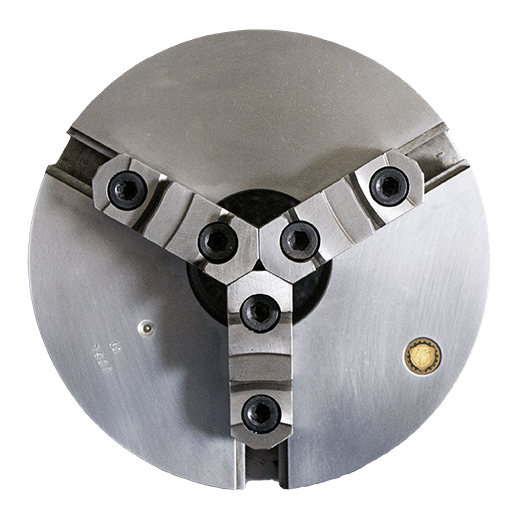

3 or 6-Jaw Scroll Chuck

For working round or hexagonal parts, consider the 3 or 6-Jaw Scroll Chuck. This chuck is adjusted with a chuck wrench (or chuck key) which aligns all jaws at once, saving you time and effort. Although scroll chucks are precise, fast, and efficient, they are not as exact as a 4-jaw independent chuck and cannot be reversed. Therefore, we suggest adding a 4-jaw independent chuck when buying this type.

4-Jaw Combination Chuck

This handy device combines the versatility of a 4-jaw independent chuck with the efficiency of the 3 or 6-jaw scroll chuck. This type has independently adjustable jaws, all of which open and close at the same time, like a 3 of 6-jaw scroll chuck. These chucks are useful for repetitive work on square, rectangular, and irregular parts that don’t require regular adjustment.

Drill Chucks

Much like a 3-jaw chuck, drill chucks are self-centering. These chucks can hold long and slender drills or parts, and have adjustable jaws. You can tighten the jaws by either hand or chuck key. Most drill chucks have a Jacob’s taper and require a Jacob’s Taper (JT) to Morse Taper (MT) arbor to use with a drill press. Despite its name, they are also very popular lathe accessories.

All About The Chuck Pt. 2

In part two of our chuck overview we’ll wrap up the different varieties of chucks and explain the last two key features to look for when choosing a chuck.

Automatic Hydraulic or Pneumatic Chuck

These foot operated chucks are designed with 2 – 6 jaws and made to work with a bar feeder. To secure the work piece the operator first activates the foot pedal, opening the chucks jaws. Next the long part is fed through the spindle bore, stopping at a pre-determined length. The chuck then clamps the part and machining begins. This configuration is ideal for running production or doing the same operation repeatedly.

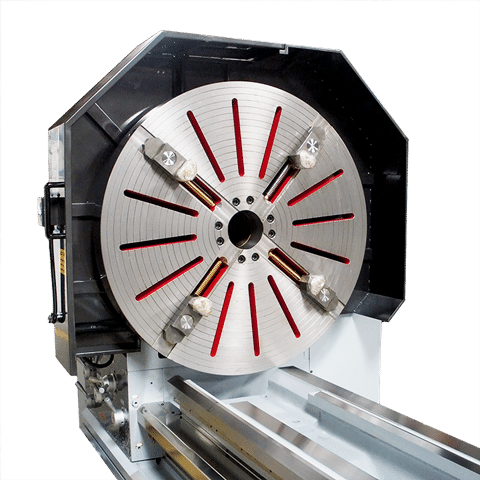

Faceplate Chuck

These simple chucks consist of a faceplate with slots and chuck jaws. A relatively inexpensive option, these chucks are generally used for large, light, and irregular work pieces.

Magnetic Chuck

Finally, we have magnetic chucks, which are commonly used on our surface grinders. There are two varieties of magnetic chucks, the permanent magnetic, and the electro magnetic chuck. These can be either standard or fine pole. The permanent magnetic is the more affordable type. The electro magnetic type requires power to be drawn from the machine for magnetization and demagnetization.

Collet Chuck

For working round or hexagonal parts, consider the 3 or 6-Jaw Scroll Chuck. This chuck is adjusted with a chuck wrench (or chuck key) which aligns all jaws at once, saving you time and effort. Although scroll chucks are precise, fast, and efficient, they are not as exact as a 4-jaw independent chuck and cannot be reversed. Therefore, we suggest adding a 4-jaw independent chuck when buying this type.

Chuck Bodies:

Another important thing to consider when adding a chuck to your machine is the material used. Lagun offers chucks that are made of either Semi-Steel or Steel. Steel body chucks are stronger and usually have a higher RPM threshold. However, the cost efficiency and accuracy of semi-steel body chucks is sufficient for most jobs, which is why they typically outsell the steel body.

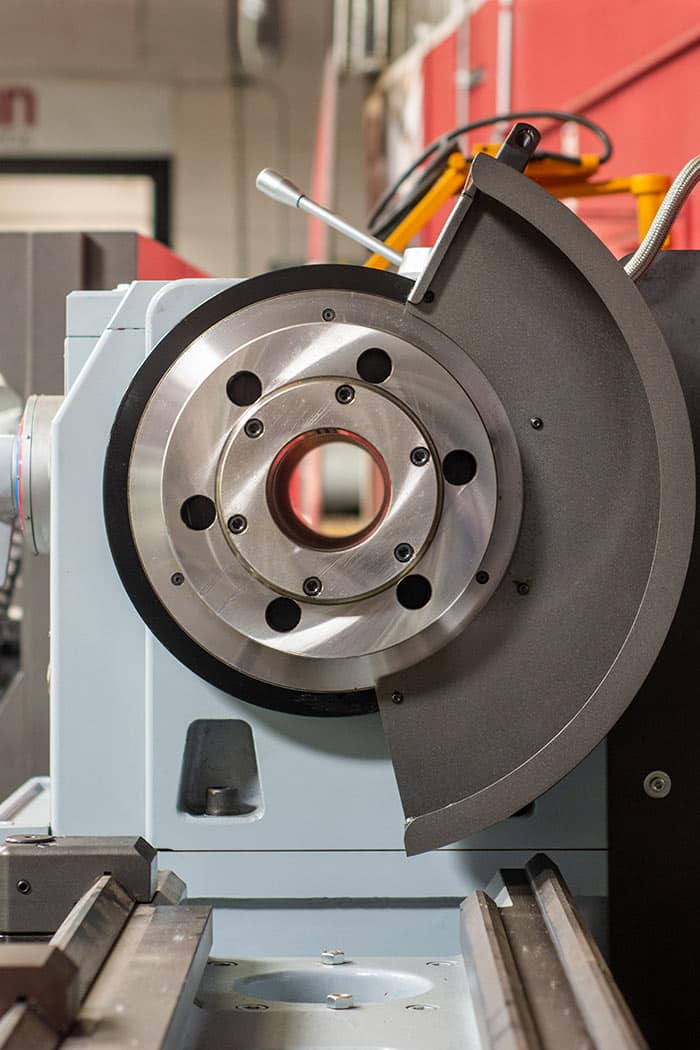

Chuck Mounts

The final piece to consider when buying a chuck is the mount. The most common mount types are the Camlock mount and the A-Mount. Less common mounts used are the “Hardinge-type” 4° Taper Mount and the Threaded Mount.

The Camlock system is quick, precise, and the most common. The back of the chuck has cams, or short poles, arranged in a circle which are inserted into the lathe spindle nose and tightened with a chuck key.

The A-mount Is the strongest and preferred when working with heavy parts and higher RPM. A-mount chucks are designed with a series of holes that correspond to holes on the spindle nose. Once the chuck is mounted screws are inserted into the holes and tightened into place.

That wraps up our chuck breakdown! We hope that the next time your in the market for a lathe you’ll remember everything you learned here. And if you still have any questions, remember to always reach out to your expert Lagun Sales Rep!