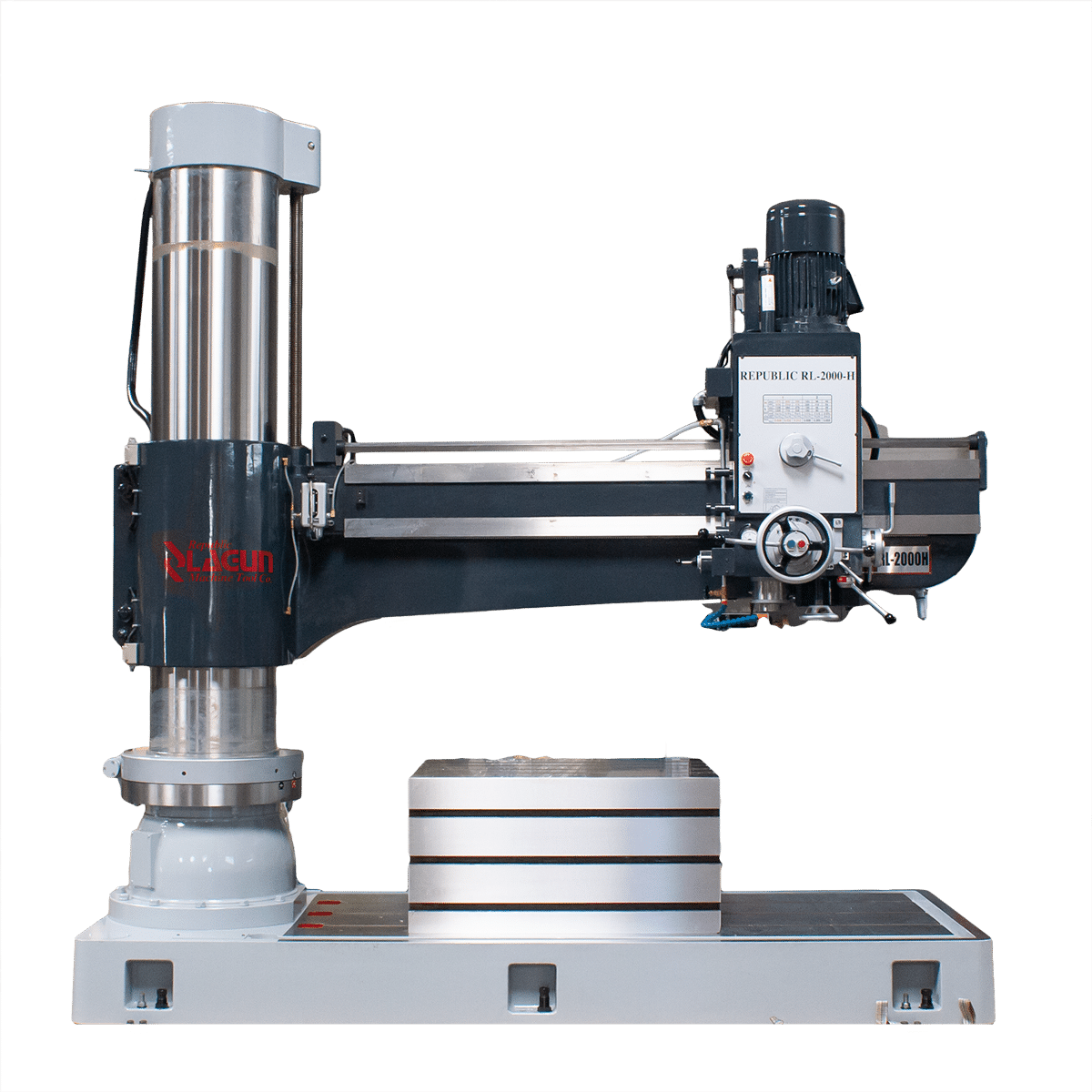

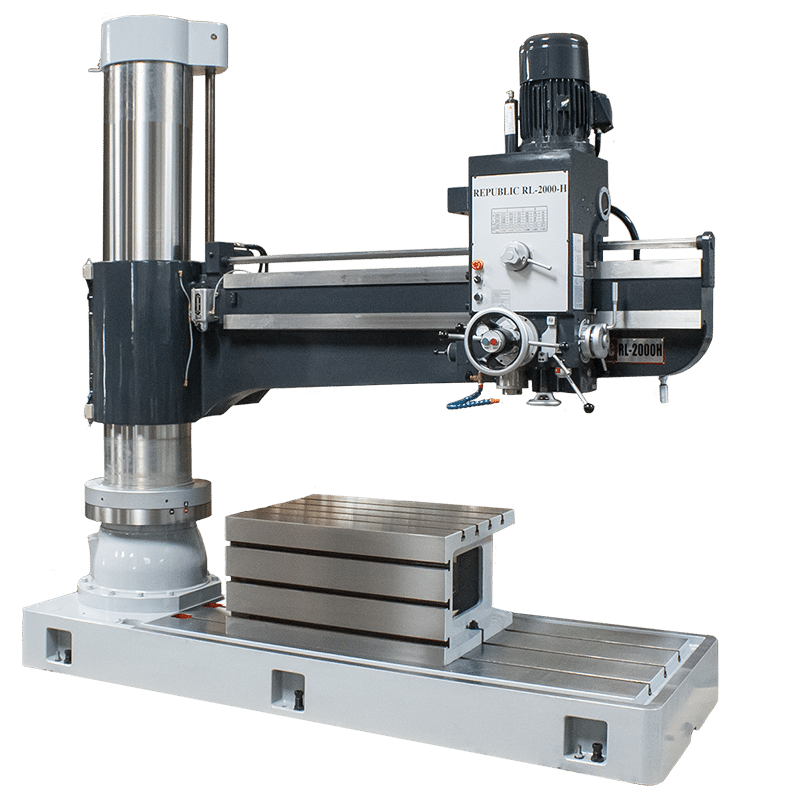

Republic Lagun Machine Tool RL-Radial Drill Nominal with electric power arm elevation

OUTSTANDING FEATURES

- Limit switches to prevent over-travel

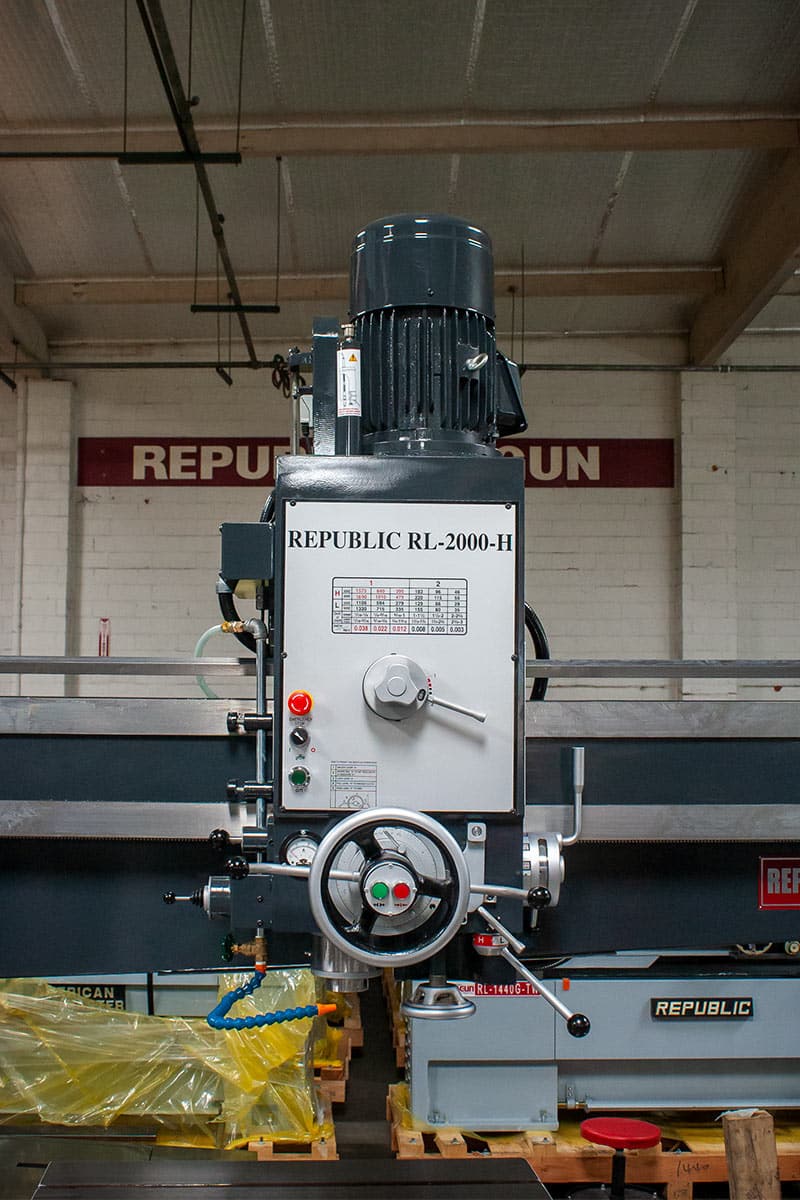

- 3 HP motor provides diverse speed selection under heavy duty cutting with automatic spindle brake.

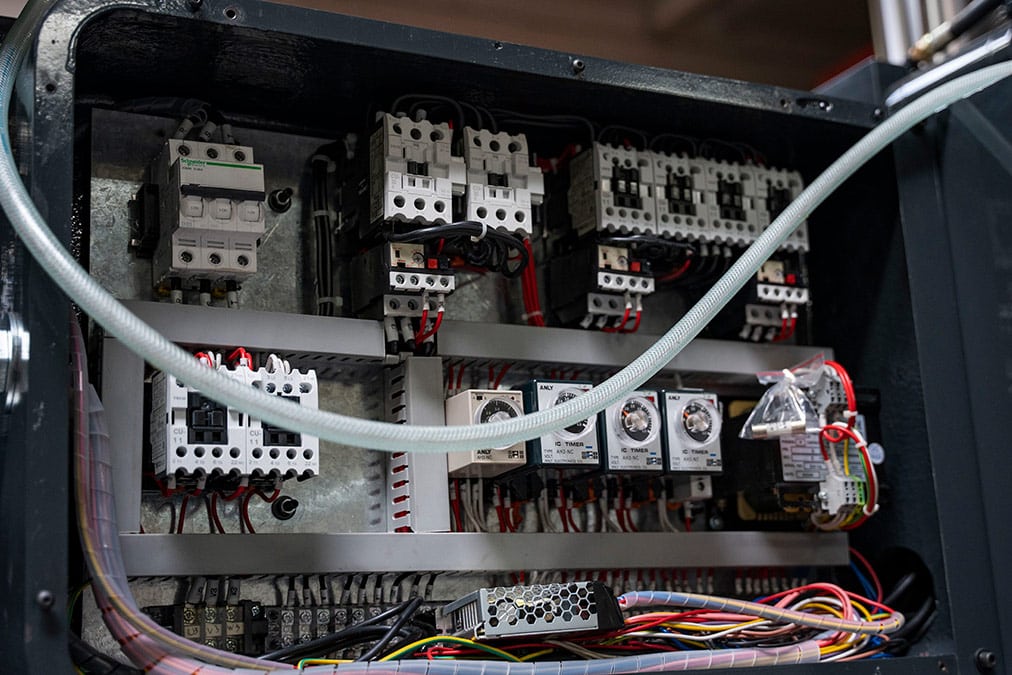

- Overload protective devices ensure operator safety

- Auxiliary dial for spindle feed depth indication

- Special balance mechanism on spindle eliminating balance and return spring which is subject to breakage

- Manual clamping of column and arm

- 12 speed gearbox on head with spindle speeds 44 ~ 1500 RPM

- Power arm elevation with anti-fall safety device

- Hardened and ground arm ways

- Manual tool ejector built into spindle

- Complete electrics (3/60/220 or 440) housed in rear of arm.

- Built in work light

- Flood coolant system

- Plain box table, 25 x 20 x 16”

- Complete with necessary manuals and service tools

Hide

DESCRIPTION

The Republic Lagun RL series are manual radial drills featuring manual clamping and electric power arm elevation. The RL-series drills provide numerous safety features to maximize operator security and a diverse speed selection under heavy-duty cutting, delivering a high level of safety and performance.

*Note: Looking for drills similar to the RL? Please contact our knowledgeable team of experts to learn about our other radial drill options today.

Check us out on Instagram for more posts and videos!

SPECIFICATIONS

| Models: | RL-855 | RL-955 | RL-1055 | RL-1230 | RL-1380 | RL-1380H | RL-1400-H | RL-1760-H | RL-1805-H | RL-2000-H | RL-2775 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Dimensions | |||||||||||

| Column diameter | 8.3” (210mm) | 8.3” (210mm) | 8.3” (210mm) | 10.2” (260 mm) | 11.8” (300 mm) | 11.8” (300 mm) | 11.8" (300 mm) | 12.6” (320 mm) | 17" (432mm) | 17" (432 mm) | 21.7" (550 mm) |

| Column Surface to Spindle Center-Min. | 8.7” (220mm) | 8.7” (220mm) | 8.7” (220mm) | 11.0” (280 mm) | 13.4” (340 mm) | 13.4” (340 mm) | 14.2" (360 mm) | 13.8” (350 mm) | 17.3" (440 mm) | 19.3" (490mm) | 19.7" (500 mm) |

| Column Surface to Spindle Center-Max. | 29.5” (750mm) | 33.5” (850mm) | 37.4” (950mm) | 43.3” (1,100 mm) | 46.1” (1,170 mm) | 46.1” (1,170 mm) | 49.2" (1,250 mm) | 63” (1,600 mm) | 62.2" (1,580 mm) | 78.7" (2000mm) | 98.4" (2,500 mm) |

| Travel of head on arm ways | 20.9” (530mm) | 24.8” (630mm) | 28.7” (730mm) | 32.3” (820 mm) | 35” (890 mm) | 35” (890 mm) | 35" (890 mm) | 49.2” (1,250 mm) | 44.9" (1,140 mm) | 59.4" (1510mm) | 78.7" (2,000 mm) |

| Spindle Face to Base Top, Min./Max. | 10.2” to 41.73” (260mm to1060mm) | 13.8” to 47.6” (350mm to 1210mm) | 13.8” to 47.6” (350mm to 1210mm) | 18.5” (470 mm) / 50” (1,270 mm) | 19.3” (490 mm) / 53.9” (1,370 mm) | 19.3” (490 mm) / 53.9” (1,370 mm) | 17.36" (441 mm) / 52.95" (1,345 mm) | 18.3” (465 mm) / 55.9” (1,420 mm) | 15" (380 mm) / 63" (1,600 mm) | 19.6" (500mm) / 74.8" (1900mm) | 21.7" (550 mm) / 78.7" (2,000 mm) |

| Arm Travel on Column (Elevating Height of Arm) | 23.8” (605mm) | 25.6” (650mm) | 25.6” (650mm) | 23.6” (600 mm) | 24.8” (630 mm) | 24.8” (630 mm) | 24.80" (630 mm) | 26.8” (680 mm) | 33.5" (850 mm) | 43.3" (1,100 mm) | 39.4" (1,000 mm) |

| Base and Column Height | 72.8” (1,850mm) | 79.1” (2,010mm) | 79.1” (2,010mm) | 78.7” (2,000mm) | 81.1” (2,060mm) | 81.1” (2,060mm) | 81.89" (2,080 mm) | 86.1” (2,186 mm) | 104.7" (2,660 mm) | 117" (2960 mm) | 151.6" (3,850 mm) |

| Machine Height From Floor – Max. | 85.4” (2,170mm) | 91.3” (2,320mm) | 91.3” (2,320mm) | 99.6” (2,530mm) | 109.4” (2,780mm) | 109.4” (2,780mm) | 104.13" (2,645 mm) | 108.7” (2,760 mm) | 124.8" (3,170 mm) | 136.6" (3470 mm) | 157.1" (3,990 mm) |

| Effective Area of Box Table | 23.6”x 17.5x 15” (600 x 445 x 380mm) | 23.6”x 17.5x 15” (600 x 445 x 380mm) | 23.6”x 17.5x 15” (600 x 445 x 380mm) | 25”x 20.5”x 16” (635 x 520 x 415mm) | 25”x 20.5”x 16” (635 x 520 x 415mm) | 25”x 20.5”x 16” (635 x 520 x 415mm) | 25" x 20.47" x 16.54" (635 x 520 x 420 mm) | 24.8”x 19.7”x 19.7” (630 x 500 x 500 mm) | 27.6"x 19.7"x 15.7" (700 x 500 x 400 mm) | 39.4"x 31.5"x 19.6" (1000 x 800 x 500 mm) | 39.4"x 31.5"x 22" (1,000 x 800 x 560 mm) |

| Dimensions of base | 49.6” x 25.2”x 6.3” (1,260 x 640 x 160mm) | 49.6” x 25.2”x 6.3” (1,260 x 640 x 160mm) | 49.6” x 25.2”x 6.3” (1,260 x 640 x 160mm) | 68” x 28”x 7” (1,725 x 715 x 180mm) | 68” x 28”x 7” (1,725 x 715 x 180mm) | 68” x 28”x 7” (1,725 x 715 x 180mm) | 70.28" x 30.91" x 7.48" (1,785 x 785 x 190 mm) | 100.4”x 38.2”x 7.9” (2,550 x 970 x 200 mm) | 97.6"x 41.3"x 8.3" (2,480 x 1,050 x 210 mm) | 114.5"x 43.4"x 9.8" (2908 x 1102 x 250 mm) | 138.6"x 55.1"x 12.6" (3,520 x 1,400 x 320 mm) |

| Shipping dimensions | 65 x 33 x 85” (1651 x 838 x 2159mm) | 67 x 33 x 87” (1702 x 838 x 2210mm) | 72 x 33 x 87” (1829 x 838 x 2210mm) | 74” x 34” x 87” (1,879 x 863 x 2,210mm) | 80.1” x 39.2” x 88.2” (2,035 x 995 x 2,240mm) | 80.1” x 39.2” x 88.2” (2,035 x 995 x 2,240mm) | 81.10"x 39.17"x 88.19" (2,060 x 995 x 2,240 mm) | 105.1”x 44.1”x 94.9” (2,670 x 1,120 x 2,410 mm) | 112.2"x 55.1"x 98" (2,850 x 1,400 x 2,490 mm) | 126"x 55.1"x 129.9" (3200 x 1400 x 3300 mm) | 157.5"x 63"x 151.6" (4,000 x 1,600 x 3,850 mm) |

| Spindle | |||||||||||

| Spindle Taper | MT #4 | MT #4 | MT #4 | MT #4 | MT #4 | MT #4 | MT #5 | MT #5 | MT #5 | MT #5 | MT #6 |

| Stroke of Spindle | 8.3” (210mm) | 8.3” (210mm) | 8.3” (210mm) | 9” (230mm) | 9.8” (250mm) | 9.8” (250mm) | 10.63" (270 mm) | 10.6” (270 mm) | 14.6" (370 mm) | 14.6" (370 mm) | 17.7" (450 mm) |

| Spindle Speeds (RPM x Steps) | 88 to 1,500 RPM x 6 | 88 to 1,500 RPM x 6 | 88 to 1,500 RPM x 6 | 44 to 1,500 RPM x 12 | 44 to 1,500 RPM x 12 | 44 to 1,500 RPM x 12 | 56 to 1,450 RPM x 12 | 56 – 1450 to RPM x 12 | 40 to 1,920 RPM x 12 | 35 to 1890 RPM x 12 | 16 to 1,250 RPM x 16 |

| Spindle power feeds (Rev. x Steps) | 0.002” - 0.006” (0.05 – 0.15mm) x 3 | 0.002” - 0.006” (0.05 – 0.15mm) x 3 | 0.002” - 0.006” (0.05 – 0.15mm) x 3 | 0.002” - 0.006” (0.05 – 0.15mm) x 3 | 0.002” – 0.004” – 0.006” (0.05 – 0.09 – 0.15mm) x 3 | 0.002” – 0.004” – 0.006” (0.05 – 0.09 – 0.15mm) x 3 | 0.002", 0.004", 0.008" (0.06, 0.10, 0.20mm) x 3 | 0.002", 0.004", 0.008" (0.06, 0.10, 0.20 mm) x 3 | 0.003" – 0.04" (0.07 – 0.96 mm) x6 | 0.003" – 0.04" (0.07 – 0.96 mm) x 6 | 0.002" – 0.13" (0.04 – 3.2 mm) x 16 |

| Drilling Capacities | |||||||||||

| Drilling Capacity in Steel | 1.5” (38mm) | 1.5” (38mm) | 1.5” (38mm) | 1.65” (42mm) | 1.65” (42mm) | 1.65” (42mm) | 2” (50mm) | 2” (50mm) | 2.55" (65mm) | 2.6" (65mm) | 3.15" (80mm) |

| Drilling Capacity in Cast Iron | 2” (50mm) | 2” (50mm) | 2” (50mm) | 2.2” (55mm) | 2.2” (55mm) | 2.2” (55mm) | 2.4” (60mm) | 2.4” (60mm) | 2.75" (70mm) | 2.8" (70mm) | 3.94 " (100mm) |

| Tapping in Steel | 1” (25mm) | 1” (25mm) | 1” (25mm) | 1” (25mm) | 1” (25mm) | 1” (25mm) | 1.57" (40mm) | 1.6” (40mm) | 2" (50mm) | 2" (50mm) | 2.56" (65mm) |

| Tapping in Cast Iron | 1.25” (32mm) | 1.25” (32mm) | 1.25” (32mm) | 1.5” (38mm) | 1.5” (38mm) | 1.5” (38mm) | 1.97" (50mm) | 2” (50mm) | 2.36" (60mm) | 2.4" (60mm) | 2.95" (75mm) |

| Boring in Steel | 2.75” (70mm) | 2.75” (70mm) | 2.75” (70mm) | 3.35” (85mm) | 3.35” (85mm) | 3.35” (85mm) | 4.3” (110mm) | 4.3” (109mm) | 5" (126mm) | 5" (126mm) | 7.91" (201mm) |

| Boring in Cast Iron | 4” (105mm) | 4” (105mm) | 4” (105mm) | 4.75” (120mm) | 4.75” (120mm) | 4.75” (120mm) | 6.5” (165mm) | 6.5” (165mm) | 7.3" (186mm) | 7.3" (186mm) | 12.20" (310mm) |

| Motors | |||||||||||

| Main motor, direct drive | 2 HP | 2 HP | 2 HP | 3 HP (2 Speed) | 3 HP (2 Speed) | 3 HP (2 Speed) | 5 HP | 5 HP, two speed motor | 7.5 HP | 7.5 HP | 10 HP |

| Arm Elevating motor | 1 HP | 1 HP | 1 HP | 1 HP | 1 HP | 1 HP | 1 HP | 2 HP | 2 HP | 3 HP | 5 HP |

| Clamping Motor | Manual | Manual | Manual | Manual | Electric | Hydraulic | 1 HP | 1 HP | Hydraulic | 1 HP | Hydraulic |

| Coolant pump motor | 1/8 HP | 1/8 HP | 1/8 HP | 1/8 HP | 1/8 HP | 1/8 HP | 1/8 HP | 1/8 HP | 1/8 HP | 1/8 HP | 1/4 HP |

| Weights | |||||||||||

| Approx. Net Weight | 2,469 lbs (1,120 Kgs) | 2,645 lbs (1,200 Kgs) | 2,755 lbs (1,250 Kgs) | 3,968 lbs (1,800 Kgs) | 4,630 lbs (2,100 Kgs) | 4,630 lbs (2,100 Kgs) | 5,070 lbs (2,300 Kgs) | 7,275 lbs (3,300 Kgs) | 10,141 lbs (4,600 Kgs) | 12,346 lbs. (5600 Kgs) | 24,251 lbs (11,000 Kgs) |

| Approx. Gross Weight | 2,755 lbs (1,250 Kgs) | 2,945 lbs (1,340 Kgs) | 3,086 lbs (1,400 Kgs) | 4,299 lbs (1,950 Kgs) | 5,070 lbs (2,300 Kgs) | 5,070 lbs (2,300 Kgs) | 5,512 lbs (2,500 Kgs) | 8,378 lbs (3,800 Kgs) | 11,244 lbs (5,100 Kgs) | 14,551 lbs. (6600 Kgs) | 27,558 lbs (12,500 Kgs) |

| Models: | RL-855 | RL-955 | RL-1055 | RL-1230 | RL-1380 | RL-1380H | RL-1400-H | RL-1760-H | RL-1805-H | RL-2000-H | RL-2775 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Dimensions | |||||||||||

| Column diameter | 8.3” (210mm) | 8.3” (210mm) | 8.3” (210mm) | 10.2” (260 mm) | 11.8” (300 mm) | 11.8” (300 mm) | 11.8″ (300 mm) | 12.6” (320 mm) | 17″ (432mm) | 17″ (432 mm) | 21.7″ (550 mm) |

| Column Surface to Spindle Center-Min. | 8.7” (220mm) | 8.7” (220mm) | 8.7” (220mm) | 11.0” (280 mm) | 13.4” (340 mm) | 13.4” (340 mm) | 14.2″ (360 mm) | 13.8” (350 mm) | 17.3″ (440 mm) | 19.3″ (490mm) | 19.7″ (500 mm) |

| Column Surface to Spindle Center-Max. | 29.5” (750mm) | 33.5” (850mm) | 37.4” (950mm) | 43.3” (1,100 mm) | 46.1” (1,170 mm) | 46.1” (1,170 mm) | 49.2″ (1,250 mm) | 63” (1,600 mm) | 62.2″ (1,580 mm) | 78.7″ (2000mm) | 98.4″ (2,500 mm) |

| Travel of head on arm ways | 20.9” (530mm) | 24.8” (630mm) | 28.7” (730mm) | 32.3” (820 mm) | 35” (890 mm) | 35” (890 mm) | 35″ (890 mm) | 49.2” (1,250 mm) | 44.9″ (1,140 mm) | 59.4″ (1510mm) | 78.7″ (2,000 mm) |

| Spindle Face to Base Top, Min./Max. | 10.2” to 41.73” (260mm to1060mm) | 13.8” to 47.6” (350mm to 1210mm) | 13.8” to 47.6” (350mm to 1210mm) | 18.5” (470 mm) / 50” (1,270 mm) | 19.3” (490 mm) / 53.9” (1,370 mm) | 19.3” (490 mm) / 53.9” (1,370 mm) | 17.36″ (441 mm) / 52.95″ (1,345 mm) | 18.3” (465 mm) / 55.9” (1,420 mm) | 15″ (380 mm) / 63″ (1,600 mm) | 19.6″ (500mm) / 74.8″ (1900mm) | 21.7″ (550 mm) / 78.7″ (2,000 mm) |

| Arm Travel on Column (Elevating Height of Arm) | 23.8” (605mm) | 25.6” (650mm) | 25.6” (650mm) | 23.6” (600 mm) | 24.8” (630 mm) | 24.8” (630 mm) | 24.80″ (630 mm) | 26.8” (680 mm) | 33.5″ (850 mm) | 43.3″ (1,100 mm) | 39.4″ (1,000 mm) |

| Base and Column Height | 72.8” (1,850mm) | 79.1” (2,010mm) | 79.1” (2,010mm) | 78.7” (2,000mm) | 81.1” (2,060mm) | 81.1” (2,060mm) | 81.89″ (2,080 mm) | 86.1” (2,186 mm) | 104.7″ (2,660 mm) | 117″ (2960 mm) | 151.6″ (3,850 mm) |

| Machine Height From Floor – Max. | 85.4” (2,170mm) | 91.3” (2,320mm) | 91.3” (2,320mm) | 99.6” (2,530mm) | 109.4” (2,780mm) | 109.4” (2,780mm) | 104.13″ (2,645 mm) | 108.7” (2,760 mm) | 124.8″ (3,170 mm) | 136.6″ (3470 mm) | 157.1″ (3,990 mm) |

| Effective Area of Box Table | 23.6”x 17.5x 15” (600 x 445 x 380mm) | 23.6”x 17.5x 15” (600 x 445 x 380mm) | 23.6”x 17.5x 15” (600 x 445 x 380mm) | 25”x 20.5”x 16” (635 x 520 x 415mm) | 25”x 20.5”x 16” (635 x 520 x 415mm) | 25”x 20.5”x 16” (635 x 520 x 415mm) | 25″ x 20.47″ x 16.54″ (635 x 520 x 420 mm) | 24.8”x 19.7”x 19.7” (630 x 500 x 500 mm) | 27.6″x 19.7″x 15.7″ (700 x 500 x 400 mm) | 39.4″x 31.5″x 19.6″ (1000 x 800 x 500 mm) | 39.4″x 31.5″x 22″ (1,000 x 800 x 560 mm) |

| Dimensions of base | 49.6” x 25.2”x 6.3” (1,260 x 640 x 160mm) | 49.6” x 25.2”x 6.3” (1,260 x 640 x 160mm) | 49.6” x 25.2”x 6.3” (1,260 x 640 x 160mm) | 68” x 28”x 7” (1,725 x 715 x 180mm) | 68” x 28”x 7” (1,725 x 715 x 180mm) | 68” x 28”x 7” (1,725 x 715 x 180mm) | 70.28″ x 30.91″ x 7.48″ (1,785 x 785 x 190 mm) | 100.4”x 38.2”x 7.9” (2,550 x 970 x 200 mm) | 97.6″x 41.3″x 8.3″ (2,480 x 1,050 x 210 mm) | 114.5″x 43.4″x 9.8″ (2908 x 1102 x 250 mm) | 138.6″x 55.1″x 12.6″ (3,520 x 1,400 x 320 mm) |

| Shipping dimensions | 65 x 33 x 85” (1651 x 838 x 2159mm) | 67 x 33 x 87” (1702 x 838 x 2210mm) | 72 x 33 x 87” (1829 x 838 x 2210mm) | 74” x 34” x 87” (1,879 x 863 x 2,210mm) | 80.1” x 39.2” x 88.2” (2,035 x 995 x 2,240mm) | 80.1” x 39.2” x 88.2” (2,035 x 995 x 2,240mm) | 81.10″x 39.17″x 88.19″ (2,060 x 995 x 2,240 mm) | 105.1”x 44.1”x 94.9” (2,670 x 1,120 x 2,410 mm) | 112.2″x 55.1″x 98″ (2,850 x 1,400 x 2,490 mm) | 126″x 55.1″x 129.9″ (3200 x 1400 x 3300 mm) | 157.5″x 63″x 151.6″ (4,000 x 1,600 x 3,850 mm) |

| Spindle | |||||||||||

| Spindle Taper | MT #4 | MT #4 | MT #4 | MT #4 | MT #4 | MT #4 | MT #5 | MT #5 | MT #5 | MT #5 | MT #6 |

| Stroke of Spindle | 8.3” (210mm) | 8.3” (210mm) | 8.3” (210mm) | 9” (230mm) | 9.8” (250mm) | 9.8” (250mm) | 10.63″ (270 mm) | 10.6” (270 mm) | 14.6″ (370 mm) | 14.6″ (370 mm) | 17.7″ (450 mm) |

| Spindle Speeds (RPM x Steps) | 88 to 1,500 RPM x 6 | 88 to 1,500 RPM x 6 | 88 to 1,500 RPM x 6 | 44 to 1,500 RPM x 12 | 44 to 1,500 RPM x 12 | 44 to 1,500 RPM x 12 | 56 to 1,450 RPM x 12 | 56 – 1450 to RPM x 12 | 40 to 1,920 RPM x 12 | 35 to 1890 RPM x 12 | 16 to 1,250 RPM x 16 |

| Spindle power feeds (Rev. x Steps) | 0.002” – 0.006” (0.05 – 0.15mm) x 3 | 0.002” – 0.006” (0.05 – 0.15mm) x 3 | 0.002” – 0.006” (0.05 – 0.15mm) x 3 | 0.002” – 0.006” (0.05 – 0.15mm) x 3 | 0.002” – 0.004” – 0.006” (0.05 – 0.09 – 0.15mm) x 3 | 0.002” – 0.004” – 0.006” (0.05 – 0.09 – 0.15mm) x 3 | 0.002″, 0.004″, 0.008″ (0.06, 0.10, 0.20mm) x 3 | 0.002″, 0.004″, 0.008″ (0.06, 0.10, 0.20 mm) x 3 | 0.003″ – 0.04″ (0.07 – 0.96 mm) x6 | 0.003″ – 0.04″ (0.07 – 0.96 mm) x 6 | 0.002″ – 0.13″ (0.04 – 3.2 mm) x 16 |

| Drilling Capacities | |||||||||||

| Drilling Capacity in Steel | 1.5” (38mm) | 1.5” (38mm) | 1.5” (38mm) | 1.65” (42mm) | 1.65” (42mm) | 1.65” (42mm) | 2” (50mm) | 2” (50mm) | 2.55″ (65mm) | 2.6″ (65mm) | 3.15″ (80mm) |

| Drilling Capacity in Cast Iron | 2” (50mm) | 2” (50mm) | 2” (50mm) | 2.2” (55mm) | 2.2” (55mm) | 2.2” (55mm) | 2.4” (60mm) | 2.4” (60mm) | 2.75″ (70mm) | 2.8″ (70mm) | 3.94 ” (100mm) |

| Tapping in Steel | 1” (25mm) | 1” (25mm) | 1” (25mm) | 1” (25mm) | 1” (25mm) | 1” (25mm) | 1.57″ (40mm) | 1.6” (40mm) | 2″ (50mm) | 2″ (50mm) | 2.56″ (65mm) |

| Tapping in Cast Iron | 1.25” (32mm) | 1.25” (32mm) | 1.25” (32mm) | 1.5” (38mm) | 1.5” (38mm) | 1.5” (38mm) | 1.97″ (50mm) | 2” (50mm) | 2.36″ (60mm) | 2.4″ (60mm) | 2.95″ (75mm) |

| Boring in Steel | 2.75” (70mm) | 2.75” (70mm) | 2.75” (70mm) | 3.35” (85mm) | 3.35” (85mm) | 3.35” (85mm) | 4.3” (110mm) | 4.3” (109mm) | 5″ (126mm) | 5″ (126mm) | 7.91″ (201mm) |

| Boring in Cast Iron | 4” (105mm) | 4” (105mm) | 4” (105mm) | 4.75” (120mm) | 4.75” (120mm) | 4.75” (120mm) | 6.5” (165mm) | 6.5” (165mm) | 7.3″ (186mm) | 7.3″ (186mm) | 12.20″ (310mm) |

| Motors | |||||||||||

| Main motor, direct drive | 2 HP | 2 HP | 2 HP | 3 HP (2 Speed) | 3 HP (2 Speed) | 3 HP (2 Speed) | 5 HP | 5 HP, two speed motor | 7.5 HP | 7.5 HP | 10 HP |

| Arm Elevating motor | 1 HP | 1 HP | 1 HP | 1 HP | 1 HP | 1 HP | 1 HP | 2 HP | 2 HP | 3 HP | 5 HP |

| Clamping Motor | Manual | Manual | Manual | Manual | Electric | Hydraulic | 1 HP | 1 HP | Hydraulic | 1 HP | Hydraulic |

| Coolant pump motor | 1/8 HP | 1/8 HP | 1/8 HP | 1/8 HP | 1/8 HP | 1/8 HP | 1/8 HP | 1/8 HP | 1/8 HP | 1/8 HP | 1/4 HP |

| Weights | |||||||||||

| Approx. Net Weight | 2,469 lbs (1,120 Kgs) | 2,645 lbs (1,200 Kgs) | 2,755 lbs (1,250 Kgs) | 3,968 lbs (1,800 Kgs) | 4,630 lbs (2,100 Kgs) | 4,630 lbs (2,100 Kgs) | 5,070 lbs (2,300 Kgs) | 7,275 lbs (3,300 Kgs) | 10,141 lbs (4,600 Kgs) | 12,346 lbs. (5600 Kgs) | 24,251 lbs (11,000 Kgs) |

| Approx. Gross Weight | 2,755 lbs (1,250 Kgs) | 2,945 lbs (1,340 Kgs) | 3,086 lbs (1,400 Kgs) | 4,299 lbs (1,950 Kgs) | 5,070 lbs (2,300 Kgs) | 5,070 lbs (2,300 Kgs) | 5,512 lbs (2,500 Kgs) | 8,378 lbs (3,800 Kgs) | 11,244 lbs (5,100 Kgs) | 14,551 lbs. (6600 Kgs) | 27,558 lbs (12,500 Kgs) |

| Models: | RL-855 | RL-955 | RL-1055 | RL-1230 | RL-1380 | RL-1380H | RL-1400-H | RL-1760-H | RL-1805-H | RL-2000-H | RL-2775 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Dimensions | |||||||||||

| Column diameter | 8.3” (210mm) | 8.3” (210mm) | 8.3” (210mm) | 10.2” (260 mm) | 11.8” (300 mm) | 11.8” (300 mm) | 11.8″ (300 mm) | 12.6” (320 mm) | 17″ (432mm) | 17″ (432 mm) | 21.7″ (550 mm) |

| Column Surface to Spindle Center-Min. | 8.7” (220mm) | 8.7” (220mm) | 8.7” (220mm) | 11.0” (280 mm) | 13.4” (340 mm) | 13.4” (340 mm) | 14.2″ (360 mm) | 13.8” (350 mm) | 17.3″ (440 mm) | 19.3″ (490mm) | 19.7″ (500 mm) |

| Column Surface to Spindle Center-Max. | 29.5” (750mm) | 33.5” (850mm) | 37.4” (950mm) | 43.3” (1,100 mm) | 46.1” (1,170 mm) | 46.1” (1,170 mm) | 49.2″ (1,250 mm) | 63” (1,600 mm) | 62.2″ (1,580 mm) | 78.7″ (2000mm) | 98.4″ (2,500 mm) |

| Travel of head on arm ways | 20.9” (530mm) | 24.8” (630mm) | 28.7” (730mm) | 32.3” (820 mm) | 35” (890 mm) | 35” (890 mm) | 35″ (890 mm) | 49.2” (1,250 mm) | 44.9″ (1,140 mm) | 59.4″ (1510mm) | 78.7″ (2,000 mm) |

| Spindle Face to Base Top, Min./Max. | 10.2” to 41.73” (260mm to1060mm) | 13.8” to 47.6” (350mm to 1210mm) | 13.8” to 47.6” (350mm to 1210mm) | 18.5” (470 mm) / 50” (1,270 mm) | 19.3” (490 mm) / 53.9” (1,370 mm) | 19.3” (490 mm) / 53.9” (1,370 mm) | 17.36″ (441 mm) / 52.95″ (1,345 mm) | 18.3” (465 mm) / 55.9” (1,420 mm) | 15″ (380 mm) / 63″ (1,600 mm) | 19.6″ (500mm) / 74.8″ (1900mm) | 21.7″ (550 mm) / 78.7″ (2,000 mm) |

| Arm Travel on Column (Elevating Height of Arm) | 23.8” (605mm) | 25.6” (650mm) | 25.6” (650mm) | 23.6” (600 mm) | 24.8” (630 mm) | 24.8” (630 mm) | 24.80″ (630 mm) | 26.8” (680 mm) | 33.5″ (850 mm) | 43.3″ (1,100 mm) | 39.4″ (1,000 mm) |

| Base and Column Height | 72.8” (1,850mm) | 79.1” (2,010mm) | 79.1” (2,010mm) | 78.7” (2,000mm) | 81.1” (2,060mm) | 81.1” (2,060mm) | 81.89″ (2,080 mm) | 86.1” (2,186 mm) | 104.7″ (2,660 mm) | 117″ (2960 mm) | 151.6″ (3,850 mm) |

| Machine Height From Floor – Max. | 85.4” (2,170mm) | 91.3” (2,320mm) | 91.3” (2,320mm) | 99.6” (2,530mm) | 109.4” (2,780mm) | 109.4” (2,780mm) | 104.13″ (2,645 mm) | 108.7” (2,760 mm) | 124.8″ (3,170 mm) | 136.6″ (3470 mm) | 157.1″ (3,990 mm) |

| Effective Area of Box Table | 23.6”x 17.5x 15” (600 x 445 x 380mm) | 23.6”x 17.5x 15” (600 x 445 x 380mm) | 23.6”x 17.5x 15” (600 x 445 x 380mm) | 25”x 20.5”x 16” (635 x 520 x 415mm) | 25”x 20.5”x 16” (635 x 520 x 415mm) | 25”x 20.5”x 16” (635 x 520 x 415mm) | 25″ x 20.47″ x 16.54″ (635 x 520 x 420 mm) | 24.8”x 19.7”x 19.7” (630 x 500 x 500 mm) | 27.6″x 19.7″x 15.7″ (700 x 500 x 400 mm) | 39.4″x 31.5″x 19.6″ (1000 x 800 x 500 mm) | 39.4″x 31.5″x 22″ (1,000 x 800 x 560 mm) |

| Dimensions of base | 49.6” x 25.2”x 6.3” (1,260 x 640 x 160mm) | 49.6” x 25.2”x 6.3” (1,260 x 640 x 160mm) | 49.6” x 25.2”x 6.3” (1,260 x 640 x 160mm) | 68” x 28”x 7” (1,725 x 715 x 180mm) | 68” x 28”x 7” (1,725 x 715 x 180mm) | 68” x 28”x 7” (1,725 x 715 x 180mm) | 70.28″ x 30.91″ x 7.48″ (1,785 x 785 x 190 mm) | 100.4”x 38.2”x 7.9” (2,550 x 970 x 200 mm) | 97.6″x 41.3″x 8.3″ (2,480 x 1,050 x 210 mm) | 114.5″x 43.4″x 9.8″ (2908 x 1102 x 250 mm) | 138.6″x 55.1″x 12.6″ (3,520 x 1,400 x 320 mm) |

| Shipping dimensions | 65 x 33 x 85” (1651 x 838 x 2159mm) | 67 x 33 x 87” (1702 x 838 x 2210mm) | 72 x 33 x 87” (1829 x 838 x 2210mm) | 74” x 34” x 87” (1,879 x 863 x 2,210mm) | 80.1” x 39.2” x 88.2” (2,035 x 995 x 2,240mm) | 80.1” x 39.2” x 88.2” (2,035 x 995 x 2,240mm) | 81.10″x 39.17″x 88.19″ (2,060 x 995 x 2,240 mm) | 105.1”x 44.1”x 94.9” (2,670 x 1,120 x 2,410 mm) | 112.2″x 55.1″x 98″ (2,850 x 1,400 x 2,490 mm) | 126″x 55.1″x 129.9″ (3200 x 1400 x 3300 mm) | 157.5″x 63″x 151.6″ (4,000 x 1,600 x 3,850 mm) |

| Spindle | |||||||||||

| Spindle Taper | MT #4 | MT #4 | MT #4 | MT #4 | MT #4 | MT #4 | MT #5 | MT #5 | MT #5 | MT #5 | MT #6 |

| Stroke of Spindle | 8.3” (210mm) | 8.3” (210mm) | 8.3” (210mm) | 9” (230mm) | 9.8” (250mm) | 9.8” (250mm) | 10.63″ (270 mm) | 10.6” (270 mm) | 14.6″ (370 mm) | 14.6″ (370 mm) | 17.7″ (450 mm) |

| Spindle Speeds (RPM x Steps) | 88 to 1,500 RPM x 6 | 88 to 1,500 RPM x 6 | 88 to 1,500 RPM x 6 | 44 to 1,500 RPM x 12 | 44 to 1,500 RPM x 12 | 44 to 1,500 RPM x 12 | 56 to 1,450 RPM x 12 | 56 – 1450 to RPM x 12 | 40 to 1,920 RPM x 12 | 35 to 1890 RPM x 12 | 16 to 1,250 RPM x 16 |

| Spindle power feeds (Rev. x Steps) | 0.002” – 0.006” (0.05 – 0.15mm) x 3 | 0.002” – 0.006” (0.05 – 0.15mm) x 3 | 0.002” – 0.006” (0.05 – 0.15mm) x 3 | 0.002” – 0.006” (0.05 – 0.15mm) x 3 | 0.002” – 0.004” – 0.006” (0.05 – 0.09 – 0.15mm) x 3 | 0.002” – 0.004” – 0.006” (0.05 – 0.09 – 0.15mm) x 3 | 0.002″, 0.004″, 0.008″ (0.06, 0.10, 0.20mm) x 3 | 0.002″, 0.004″, 0.008″ (0.06, 0.10, 0.20 mm) x 3 | 0.003″ – 0.04″ (0.07 – 0.96 mm) x6 | 0.003″ – 0.04″ (0.07 – 0.96 mm) x 6 | 0.002″ – 0.13″ (0.04 – 3.2 mm) x 16 |

| Drilling Capacities | |||||||||||

| Drilling Capacity in Steel | 1.5” (38mm) | 1.5” (38mm) | 1.5” (38mm) | 1.65” (42mm) | 1.65” (42mm) | 1.65” (42mm) | 2” (50mm) | 2” (50mm) | 2.55″ (65mm) | 2.6″ (65mm) | 3.15″ (80mm) |

| Drilling Capacity in Cast Iron | 2” (50mm) | 2” (50mm) | 2” (50mm) | 2.2” (55mm) | 2.2” (55mm) | 2.2” (55mm) | 2.4” (60mm) | 2.4” (60mm) | 2.75″ (70mm) | 2.8″ (70mm) | 3.94 ” (100mm) |

| Tapping in Steel | 1” (25mm) | 1” (25mm) | 1” (25mm) | 1” (25mm) | 1” (25mm) | 1” (25mm) | 1.57″ (40mm) | 1.6” (40mm) | 2″ (50mm) | 2″ (50mm) | 2.56″ (65mm) |

| Tapping in Cast Iron | 1.25” (32mm) | 1.25” (32mm) | 1.25” (32mm) | 1.5” (38mm) | 1.5” (38mm) | 1.5” (38mm) | 1.97″ (50mm) | 2” (50mm) | 2.36″ (60mm) | 2.4″ (60mm) | 2.95″ (75mm) |

| Boring in Steel | 2.75” (70mm) | 2.75” (70mm) | 2.75” (70mm) | 3.35” (85mm) | 3.35” (85mm) | 3.35” (85mm) | 4.3” (110mm) | 4.3” (109mm) | 5″ (126mm) | 5″ (126mm) | 7.91″ (201mm) |

| Boring in Cast Iron | 4” (105mm) | 4” (105mm) | 4” (105mm) | 4.75” (120mm) | 4.75” (120mm) | 4.75” (120mm) | 6.5” (165mm) | 6.5” (165mm) | 7.3″ (186mm) | 7.3″ (186mm) | 12.20″ (310mm) |

| Motors | |||||||||||

| Main motor, direct drive | 2 HP | 2 HP | 2 HP | 3 HP (2 Speed) | 3 HP (2 Speed) | 3 HP (2 Speed) | 5 HP | 5 HP, two speed motor | 7.5 HP | 7.5 HP | 10 HP |

| Arm Elevating motor | 1 HP | 1 HP | 1 HP | 1 HP | 1 HP | 1 HP | 1 HP | 2 HP | 2 HP | 3 HP | 5 HP |

| Clamping Motor | Manual | Manual | Manual | Manual | Electric | Hydraulic | 1 HP | 1 HP | Hydraulic | 1 HP | Hydraulic |

| Coolant pump motor | 1/8 HP | 1/8 HP | 1/8 HP | 1/8 HP | 1/8 HP | 1/8 HP | 1/8 HP | 1/8 HP | 1/8 HP | 1/8 HP | 1/4 HP |

| Weights | |||||||||||

| Approx. Net Weight | 2,469 lbs (1,120 Kgs) | 2,645 lbs (1,200 Kgs) | 2,755 lbs (1,250 Kgs) | 3,968 lbs (1,800 Kgs) | 4,630 lbs (2,100 Kgs) | 4,630 lbs (2,100 Kgs) | 5,070 lbs (2,300 Kgs) | 7,275 lbs (3,300 Kgs) | 10,141 lbs (4,600 Kgs) | 12,346 lbs. (5600 Kgs) | 24,251 lbs (11,000 Kgs) |

| Approx. Gross Weight | 2,755 lbs (1,250 Kgs) | 2,945 lbs (1,340 Kgs) | 3,086 lbs (1,400 Kgs) | 4,299 lbs (1,950 Kgs) | 5,070 lbs (2,300 Kgs) | 5,070 lbs (2,300 Kgs) | 5,512 lbs (2,500 Kgs) | 8,378 lbs (3,800 Kgs) | 11,244 lbs (5,100 Kgs) | 14,551 lbs. (6600 Kgs) | 27,558 lbs (12,500 Kgs) |

Hide

* All Product Specs are Subject to Change at Any Time

One year or 2,000 hours from date of installation, (single shifting) whichever occurs first. For parts and service contact our support team at:

or call

800.421.2105

*Applies to domestic sales only.