Machine Spotlight: Gianna's Deep Hole Boring GGB

Machine Spotlight: Gianna's Deep Hole Boring GGB

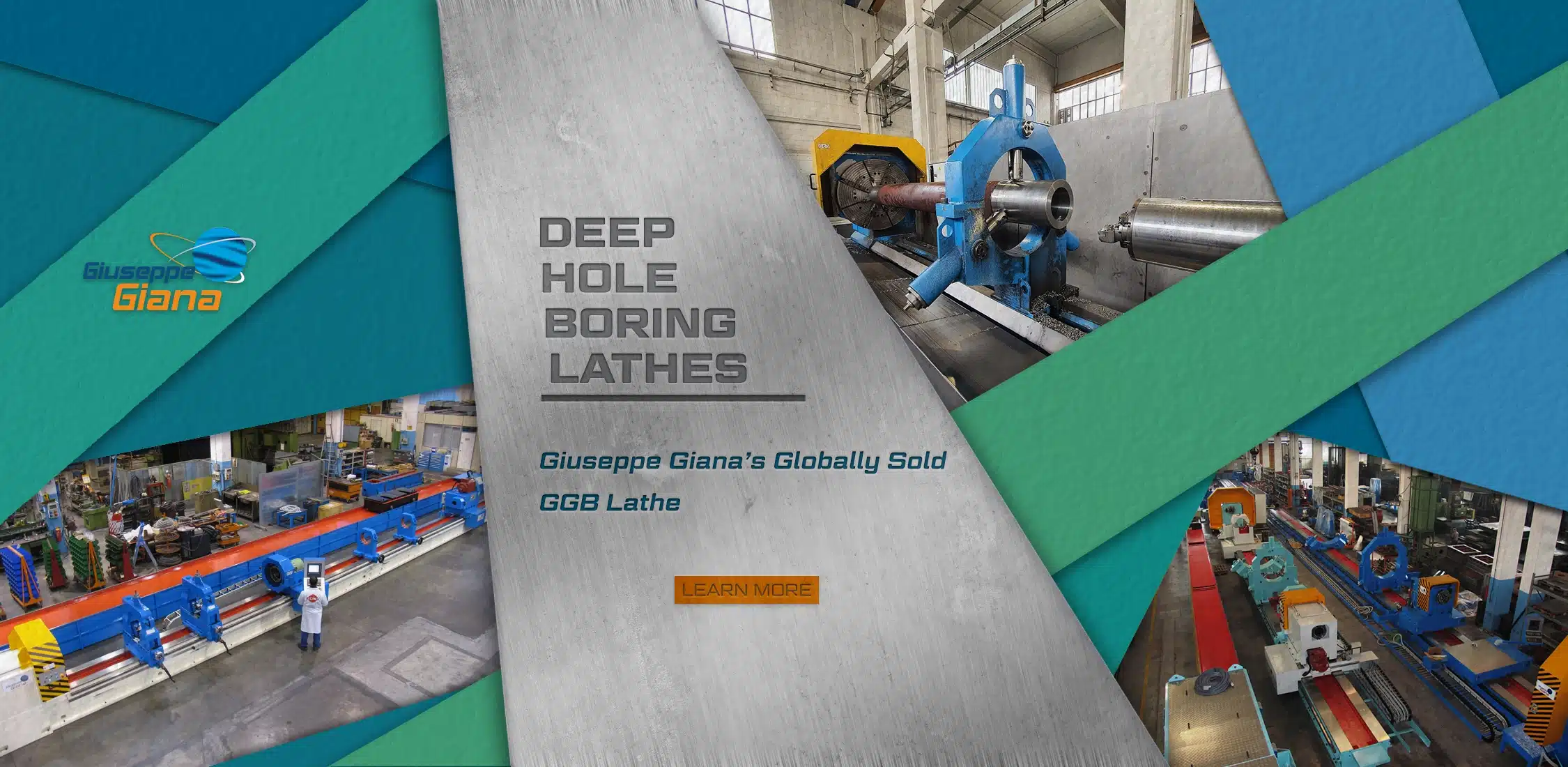

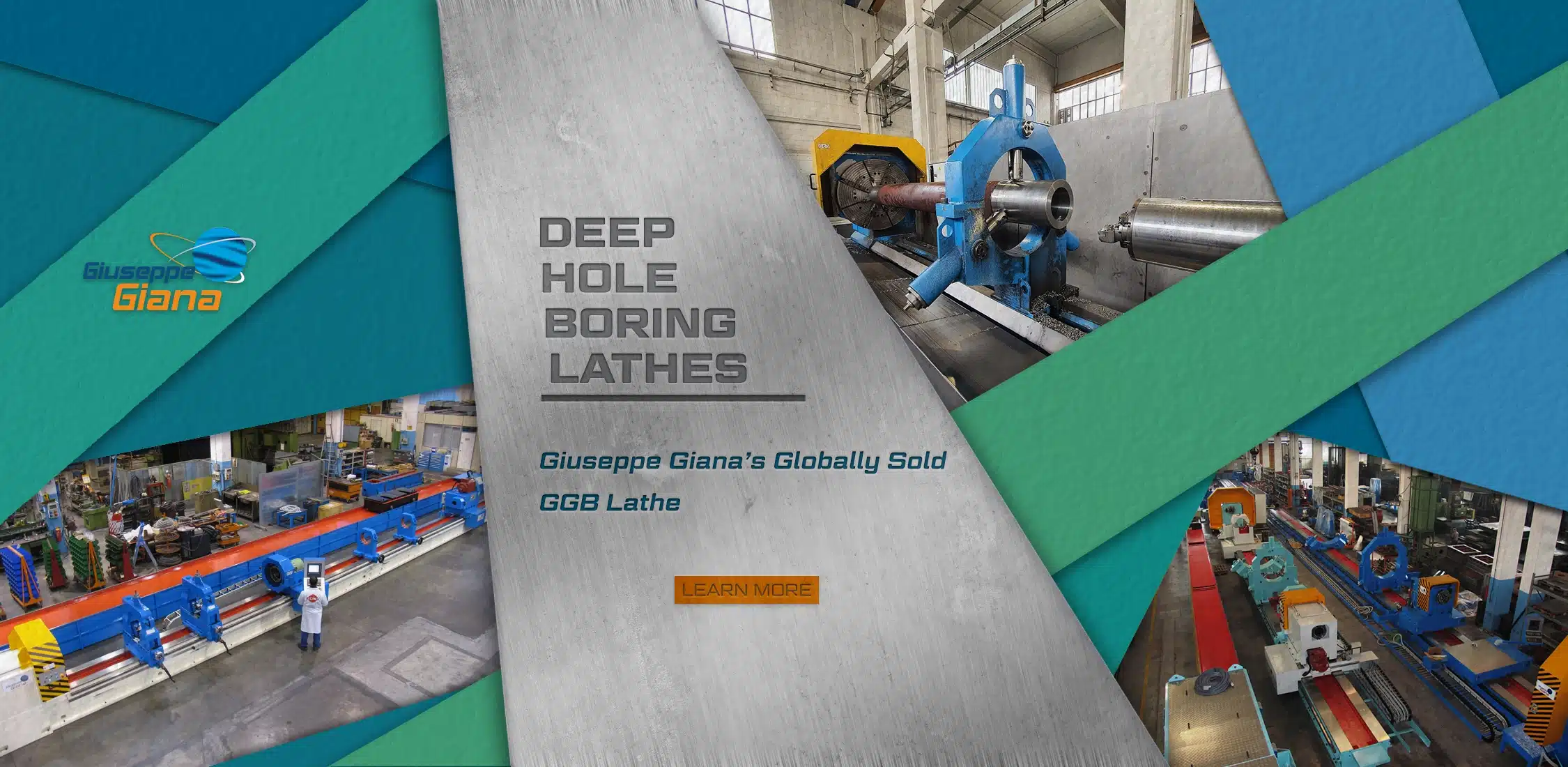

Giana's Deep Hole Boring Lathes

Today we’re diving back into our machine spotlight series by shining the light on another of our exclusive Giuseppe Giana products. Previously we’ve explored Giana’s GG-Tronic multi-tasking lathes. In this edition we’ll look at their global leading deep hole boring lathes, the GGB. This machine, which comes in several sizes and configurations, boasts an ultra-rigid body that maintains precision no matter the size or heft of the project. This CNC model lathe is particularly matched for bottle boring, a process typically used on aerospace landing gear and actuator applications. The GGB’s unique features and design make it perfectly suited for the Aerospace, Power, Oil, and Naval sectors.

The GGB’s Innovative Design

Giana’s decades in the machine tool industry have led them to develop a unique bed way configuration which ultimately inhibits any vibration on the carriage or tool bed. Giana has equipped their GGB with 2 separated beds, each with multiple anchoring/fixing points. This ensures an increase in the machine’s stability and accuracy throughout the entirety of the machine’s life. The lathes cross-slides are placed lower than the rear-side ways. Because of this there is no hindrance of the cross slides full turning capacity/swing over bed dimension. Therefore, you can achieve the same results as a larger swing lathe.

The lathes high quality X and Z axes roller guides ensure extremely fluid axes movements. The flat guides are configured to be only on the tailstock’s bed. The distribution of force is therefore not affected because it’s made on the high load capacity front bed guides of the carriage. Furthermore, future maintenance becomes easier because this deign enables the user to conveniently change a part of the guide without demounting the complete carriage, eliminating the need to re-adjust the conical gibs.

The Ergonomic GGB

The structure of the GGB’s bed ways translates to a more convenient design that easily accommodates the operator’s tasks of measuring, loading and/or unloading the workpiece. Due to the separation of the front and rear ways, the operator’s normal position (atop the carriage) is a more comfortable, ergonomically designed space. This results in the operator being closer to the part, requiring less reach for random tasks, resulting in less fatigue for the operator.

Options For The GGB

At Lagun we like to make sure you leave with a machine perfectly matched for your every need. Our team of machine tool experts are happy to work with you to add any available options to any machine you’re interested in. One option included with the GGB is the addition of a vacuum system to the enclosure, which allows for a cleaner and healthier workspace for operator safety. Contact us today to learn more about this sophisticated machines and all it’s optional features and accessories.

About Giuseppe Giana

With Guiseppe Giana’s 30 plus years of knowledge, and constantly evolving facilities, workflow and technology, it’s easy to understand why they are considered artisans of their craft. Founded in 1964, Giuseppe Giana SPA specializes in constructing CNC turning machines with 4-bed guideways and CNC deep hole drilling and boring machines. The company uses its large pool of advanced machine tools for contract machining and the production of components new machines. Giuseppe Giana Spa makes grinding machines, boring machines, milling machines, and milling and planing machines, including one of Europe’s largest grinder for flat surfaces. The passion and precision Giana brings to every machine has allowed them to grow their company from their homeland in Italy to countries like India, USA, Brazil, Denmark, France, Russia, Germany, Israel, Turkey, exc.