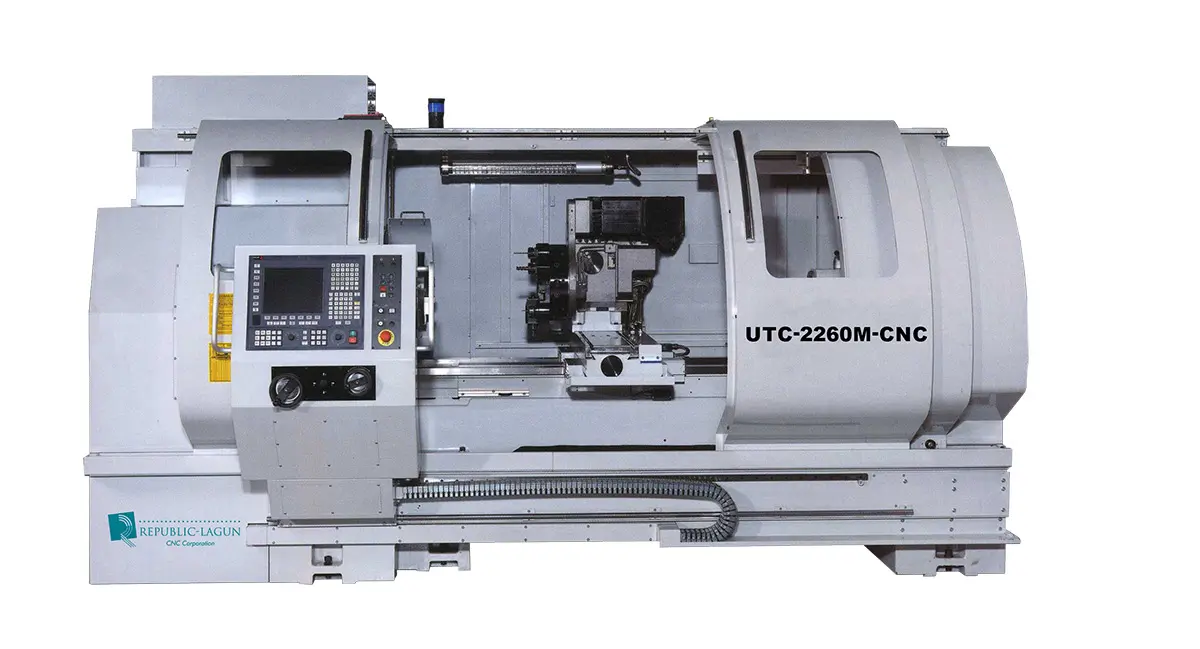

Republic Lagun CNC UTC-2260 Universal Turning Center

OUTSTANDING FEATURES

- Meehanite casting – Machine frame is cast of rugged Meehanite with heavy ribbing for superior rigidity and vibration dampening. The rigidity contributes to durability of machine and tooling, as well as precision of actual machining performance.

- Induction hardened and precision-ground bed ways – Bed design with 2 “V” and 2 flat ways which are induction hardened to provide maximum life and then ground to allow for precision carriage movement along the Z axis.

- Unique spindle design – supported by single cylinder bearing housing equipped with SP level precision double row cylindrical roller bearings, angular contact thrust bearings and lubricated with high-class grease.

- Spindle power – Broad range of programmable spindle speeds with constant surface speed (CSS).

- Headstock – The headstock is enclosed and well-ribbed for maximum heat dissipation. This construction prevents any thermal distortion after long periods of turning, ensuring accurate cutting.

- Laser Verification – All UTC’s are laser verified ±0.0005” (±0.01 mm) positioning accuracy over the full X and Y axes travel before being shipped.

- Z-axis with the 2” (or 2.5” on 120” b/c machine) precision ground ball screw is the largest in class and aligns the tool in the cut for rigid and smooth operation.

- X axis is supported with a heavy-duty full length slide riding on Turcite stick-slip, anti-friction surfaces.

DESCRIPTION

Lagun Engineering’s UTC-2260 Universal Turning Center, one of the most versatile machines on the market today. This outstanding machine comes equipped with an extra-large 3.58” (91 mm) spindle bore with A2-8 spindle mount, and a pressure pump located in its base to lubricate the head by cool, clean oil. These machines also feature ultra-rigid bed casting mounted on cast iron pedestal. This ultra rigid body along with its induction hardened and precision ground four ways (two-V’s / two-flat ways) result in more accurate job results. The UTC-2260 Universal Turning Center is the ideal machine for for tool rooms, job shop, and prototype shops, chucking or long shaft applications.

*Note: Interested in more Universal Turning Center lathes? Please take a look at our UTC-2240/60/80/120 and UTC-1740 models. Or feel free to browse all our CNC Lathes here.

Check us out on Instagram for more posts and videos!

SPECIFICATIONS

| MODEL: | UTC-1440 | UTC-1640 | UTC-1660 | UTC-1740 | UTC-1760 | UTC-1840 | UTC-1860 | UTC 2240 | UTC 2260 | UTC 2280 | UTC 22120 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of control axis | 2 AXIS | 2 AXIS | 2 AXIS | 2 AXIS | |||||||

| Swing over the bed | 14.17” (360 mm) | 16.14” (410 mm) | 16.14” (410 mm) | Ø 17.12" (435mm) | Ø 17.12" (435mm) | Ø 18.11" (460mm) | Ø 18.11" (460mm) | Ø 22” (550 mm) | Ø 22” (550 mm) | Ø 22” (550 mm) | Ø 22” (550 mm) |

| Swing over the cross slide | 7.08” (180 mm) | 9.05” (230 mm) | 9.05” (230 mm) | ||||||||

| Distance between centers | 35” (880 mm) | 35” (880 mm) | 55” (1400 mm) | 37.40” (950mm) | 57.08” (1450mm) | 35.43” (900mm) | 55.11” (1400mm) | 34.25” (870 mm) | 53.93” (1370 mm) | 73.62” (1870 mm) | 113” (2870 mm) |

| Working length Max (4 way tool post / Hyd. P8 turret) | 29.52”(750mm)/ 24.8”(630mm) | 29.52”(750mm)/ 24.8”(630mm) | 49.61”(1260mm)/ 44.88”(1140mm) | 31.50” (800mm)/ 25.59” (650mm) | 51.18” (1300mm)/ 45.27” (1150mm) | 29.52” (750mm)/ 23.62” (600mm) | 49.21” (1250mm)/ 43.3” (1100mm) | 26.77” (680 mm) | 46.45” (1180 mm) | 66.14” (1680 mm) | 105.5” (2680 mm) |

| Working Dia. Max (4 way tool post / Hyd. P8 turret) | 6.7”(170mm)/ 6.29”(160mm) | 8.66”(220mm)/ 8.27”(210mm) | 8.66”(220mm)/ 8.27”(210mm) | 9.0” (230mm)8.66” (220mm) | 9.0” (230mm)8.66” (220mm) | 10.2” (260mm)/ 9.84” (250mm) | 10.2” (260mm)/ 9.84” (250mm) | Ø 12.8” (325 mm) | Ø 12.8” (325 mm) | Ø 12.8” (325 mm) | Ø 12.8” (325 mm) |

| Bed Width | 10.236” (260 mm) | 10.236” (260 mm) | 10.236” (260 mm) | 12” (305mm) | 12” (305mm) | 12” (305mm) | 12” (305mm) | 13.58” (345 mm) | 13.58” (345 mm) | 13.58” (345 mm) | 13.58” (345 mm) |

| Bed Ways (induction hardened & ground) | 3 “V”, 3 flat | 3 “V”, 3 flat | 3 “V”, 3 flat | 2 “V”, 2 flat | 2 “V”, 2 flat | 2 “V”, 2 flat | 2 “V”, 2 flat | ||||

| Cross slide (X) travel | 8.07” (205 mm) | 8.5” (216 mm) | 9.05” (230mm) | 9.05” (230mm) | 9.05” (230mm) | 9.05” (230mm) | 11.8” (300 mm) | 11.8” (300 mm) | 11.8” (300 mm) | 11.8” (300 mm) | |

| Longitudinal (Z) travel | 32.08” (815 mm) | 32.08” (815 mm) | 52.16” (1325 mm) | 35.43” (900mm) | 55.11” (1400mm) | 33.46” (850mm) | 53.15” (1350mm) | 30.7” (780 mm) | 50.4” (1280 mm) | 70.1” (1780 mm) | 109.4” (2780 mm) |

| Spindle nose, Standard | Camlock D1-6 or Optional ASA A1-6 | Camlock D1-6 or Optional ASA A1-7 | Camlock D1-6 or Optional ASA A1-8 | D1-6 MT (OPT. A1-6) | D1-6 MT (OPT. A1-6) | A2-6, Ø69 mm | A2-6, Ø69 mm | ASA A2-8, Ø 3.8” (97 mm) | ASA A2-8, Ø 3.8” (97 mm) | ASA A2-8, Ø 3.8” (97 mm) | ASA A2-8, Ø 3.8” (97 mm) |

| Spindle bore | 2.066” (52.5 mm) | 2.066” (52.5 mm) | 2.066” (52.5 mm) | Ø 2.06” (52.5mm), OPT. Ø 2” (51mm) | Ø 2.06” (52.5mm), OPT. Ø 2” (51mm) | Ø 2.56" (65mm) | Ø 2.56" (65mm) | Ø 3.5” (91 mm) / Ø 3.07” (78 mm) | Ø 3.5” (91 mm) / Ø 3.07” (78 mm) | Ø 3.5” (91 mm) / Ø 3.07” (78 mm) | Ø 3.5” (91 mm) / Ø 3.07” (78 mm) |

| Spindle taper | No. 6 MT | No. 6 MT | No. 6 MT | No. 6 MT | No. 6 MT | Taper 1/20 | Taper 1/20 | Taper 1/20 | Taper 1/20 | Taper 1/20 | Taper 1/20 |

| Spindle speeds | 25~3000 RPM (Pneumatic Auto-Shift) | 25~3000 RPM (Pneumatic Auto-Shift) | 25~3000 RPM (Pneumatic Auto-Shift) | Infinitely variable | Infinitely variable | Infinitely variable | Infinitely variable | Infinitely variable | Infinitely variable | Infinitely variable | Infinitely variable |

| Range | L: 25~480 RPM (Infinitely Variable)H: 481~3000 RPM (Infinitely Variable) | L: 25~480 RPM (Infinitely Variable)H: 481~3000 RPM (Infinitely Variable) | L: 25~480 RPM (Infinitely Variable)H: 481~3000 RPM (Infinitely Variable) | L: 30 ~ 450 RPMH: 451 ~ 2800 RPM | L: 30 ~ 450 RPMH: 451 ~ 2800 RPM | L: 270 ~ 830 RPM H: 831 ~ 2500 RPM | L: 270 ~ 830 RPM H: 831 ~ 2500 RPM | 35-3,500 rpm | 35-3,500 rpm | 35-3,500 rpm | 35-3,500 rpm |

| Gear steps | Pneumatic change 2 steps | Pneumatic change 2 steps | Pneumatic change 2 steps | Pneumatic change 2 steps | |||||||

| Main spindle motor | 10 HP (7.5 Kw) / 30 min rated 15HP (11Kw) | 11 HP (7.5 Kw) / 30 min rated 15HP (11Kw) | 12 HP (7.5 Kw) / 30 min rated 15HP (11Kw) | AC 7.5 HP (5.5 kW) | AC 7.5 HP (5.5 kW) | STD AC 11HP (7.5 kW)/ STD AC 15 HP (11 kW) | STD AC 11HP (7.5 kW)/ STD AC 15 HP (11 kW) | AC 12 HP (9 kW) wide range heavy duty Fanuc AC spindle motor | AC 12 HP (9 kW) wide range heavy duty Fanuc AC spindle motor | AC 12 HP (9 kW) wide range heavy duty Fanuc AC spindle motor | AC 12 HP (9 kW) wide range heavy duty Fanuc AC spindle motor |

| Tool station: | STD. Manual 4 way tool post; Optional: Elec. H4 or Hydraulic P8 turret | STD. Manual 4 way tool post; Optional: Elec. H4 or Hydraulic P8 turret | STD. Manual 4 way tool post; Optional: Elec. H4 or Hydraulic P8 turret | Manual 4-way tool post (STD) | Manual 4-way tool post (STD) | Manual 4-way tool post (STD) | Manual 4-way tool post (STD) | ||||

| Size of external turning tool | Tool section 0.78” (20mm). | Tool section 0.78” (20mm). | Tool section 0.78” (20mm). | 1” (25 mm) | 1” (25 mm) | 1” (25 mm) | 1” (25 mm) | ||||

| Boring Bar diameter | 0.78” (20mm). | 0.78” (20mm). | 0.78” (20mm). | Manual 4 way tool post / Ø 0.79” (20mm) | Manual 4 way tool post / Ø 0.98” (25mm) | Manual 4 way tool post / Ø 0.98” (25mm) | |||||

| Quill diameter | 2.283” (58 mm) | 2.283” (58 mm) | 2.283” (58 mm) | Ø 2.67” (68mm) | Ø 2.67” (68mm) | Ø 2.67” (68mm) | Ø 2.67” (68mm) | Ø 3.35” (85 mm) | Ø 3.35” (85 mm) | Ø 3.35” (85 mm) | Ø 3.35” (85 mm) |

| Quill taper | # 4 MT | # 4 MT | # 4 MT | MT No. 4 | MT No. 5 | #5 MT | #5 MT | #5 MT | #5 MT | ||

| Quill travel | 5.5” (140 mm) | 5.5” (140 mm) | 5.5” (140 mm) | 6” (153mm) | 6” (153mm) | 6” (153mm) | 6” (153mm) | 7” (178 mm) | 7” (178 mm) | 7” (178 mm) | 7” (178 mm) |

| AC servo motor ( X-axis / Z-axis ) | 0.85 kW 5.39 N.m/ 1.3 kW 8.34 N.m | 0.85 kW 5.39 N.m/ 1.3 kW 8.34 N.m | 7.0N.m ~ FANUC ß8 / 3000is | 7.0N.m ~ FANUC ß8 / 3000is | |||||||

| Servo drive motors (X / Z) | 1 HP (0.75 kW, 3.5 Nm)/ 1.61 HP (1.2 kW, 7 Nm) | 1 HP (0.75 kW, 3.5 Nm)/ 1.61 HP (1.2 kW, 7 Nm) | 1 HP (0.75 kW, 3.5 Nm)/ 1.61 HP (1.2 kW, 7 Nm) | ||||||||

| Ball screw Dia. (X / Z) | 0.787” (20 mm) (P5, C5)/ 1.260” (32 mm) (P10, C5) | 0.787” (20 mm) (P5, C5)/ 1.260” (32 mm) (P10, C5) | 0.787” (20 mm) (P5, C5)/ 1.260” (32 mm) (P10, C5) | Ø 0.787” (20 mm) P5 C5/ Ø 1.57” (40 mm) P10 C5 | Ø 0.787” (20 mm) P5 C5/ Ø 1.57” (40 mm) P10 C5 | Ø 1.57" (20mm) P10 C5/ Ø 0.787" (40mm) P5 C5 | Ø 1.57" (20mm) P10 C5/ Ø 0.787" (40mm) P5 C5 | Ø 0.98”(25 mm) P5 C5/ Ø 1.97” (50 mm) P10 C5 | Ø 0.98”(25 mm) P5 C5/ Ø 1.97” (50 mm) P10 C5 | Ø 0.98”(25 mm) P5 C5/ Ø 1.97” (50 mm) P10 C5 | Ø 0.98”(25 mm) P5 C5/ Ø 2.48” (63 mm) P10 C5 |

| Rapid traverse (X / Z) | 295 IPM (7.5MPM)/ 394 IPM (10MPM) | 295 IPM (7.5MPM)/ 394 IPM (10MPM) | 295 IPM (7.5MPM)/ 394 IPM (10MPM) | 196.8 ipm (5 m/min) / 295.3 ipm (7.5 m/min) | 196.8 ipm (5 m/min) / 295.3 ipm (7.5 m/min) | 295 ipm (7.5 m/min) / 394 ipm (10 m/min) | 295 ipm (7.5 m/min) / 394 ipm (10 m/min) | X = 295 ipm (7.5 mpm)Z = 394 ipm (10mpm) | X = 295 ipm (7.5 mpm)Z = 394 ipm (10mpm) | X = 295 ipm (7.5 mpm)Z = 394 ipm (10mpm) | X = 295 ipm (7.5 mpm)Z = 394 ipm (10mpm) |

| Positioning accuracy | ±0.0002” (±0.005 mm) | ±0.0002” (±0.005 mm) | ±0.0002” (±0.005 mm) | ± 0.0005” (0.01 mm) | ± 0.0005” (0.01 mm) | ± 0.0005” (0.01 mm) | ± 0.0005” (0.01 mm) | ||||

| Repeatability | ±0.0002” (±0.005 mm) | ±0.0002” (±0.005 mm) | ±0.0002” (±0.005 mm) | ± 0.0002” (0.005 mm) | ± 0.0002” (0.005 mm) | ± 0.0002” (0.005 mm) | ± 0.0002” (0.005 mm) | ||||

| Resolution | ±0.0001” (±0.00254 mm) | ±0.0001” (±0.00254 mm) | ±0.0001” (±0.00254 mm) | ± 0.0001” (0.002 mm) | ± 0.0001” (0.002 mm) | ± 0.0001” (0.002 mm) | ± 0.0001” (0.002 mm) | ||||

| Hydraulic tank | STD 5.5 gal (25 L), OPT 8.8 gal (40 L) | STD 5.5 gal (25 L), OPT 8.8 gal (40 L) | STD 5.5 gal (25 L), OPT 8.8 gal (40 L) | STD 5.5 gal (25 L), OPT 8.8 gal (40 L) | 6.6 gal. (25 liters) – STD , 10.5 gal. (40 liters) – Optional | 6.6 gal. (25 liters) – STD , 10.5 gal. (40 liters) – Optional | 6.6 gal. (25 liters) – STD , 10.5 gal. (40 liters) – Optional | 6.6 gal. (25 liters) – STD , 10.5 gal. (40 liters) – Optional | |||

| Coolant tank | 50L (11gl) | 50L (11gl) | 70L (15.4gl) | 13.2 gal (60 L) | 19.7 gal (85 L) | 13.2 gal (60 L) | 19.7 gal (85 L) | 15.85 gal. (60 liters) | 31.70 gal. (120 liters) | 47.5 gal. (180 liters) | 63.40 gal. (240 liters) |

| Hydraulic oil pump | OPT. 1HP (0.75kw) | OPT. 1HP (0.75kw) | OPT. 2HP (1.5kw) | OPT. 1 HP (0.75 kW), OPT. 2 HP (1.5kW) | OPT. 1 HP (0.75 kW), OPT. 2 HP (1.5kW) | OPT. 1HP (0.75 kW), OPT. 2HP (1.5kW) | |||||

| Forced lubrication for headstock | ¼ HP(0.18KW) | ¼ HP(0.18KW) | ¼ HP(0.18KW) | ¼ HP | ¼ HP | ¼ HP | ¼ HP | ||||

| Coolant pump | 70L (15.4gl) | 70L (15.4gl) | 70L (15.4gl) | 1/6 HP | 1/6 HP | 1/6 HP | 1/6 HP | ||||

| Weight (Net/Gross) Approx. | 4629 lbs (2100 Kgs.)/ 5732 lbs (2600 Kgs.) | 4739 lbs (2150 Kgs.)/ 5842 lbs (2650 Kgs.) | 4960lbs (2250 Kgs.)/ 6062 lbs (2750Kgs.) | 4739 lbs / 5842 lbs 2150 kgs / 2650 kgs) | 5291 lbs / 6393 lbs (2400 kgs/2900 kgs) | 5170 lbs / 6270 lbs (2350 kgs / 2850 kgs) | 5720 lbs / 6820 lbs (2600 kgs/3100 kgs) | 4050 kg/4450 kg | 4400 kg/4900 kg | 4800 kg/5400 kg | 5300 kg/6000 kg |

| Packing Sizes (L x W x H) | 97.24”(2470mm) x 80”(2030mm) x 87”(2200mm) | 97.24”(2470mm) x 80”(2030mm) x 87”(2200mm) | 117”(2980mm) x 80”(2030mm) x 87”(2200mm) | 104.72” (2660m) x 79.33” x 88.2” (2015mm x 2240mm) | 124.4” (3160mm) x 79.33” x 88.2” (2015mm x 2240mm) | 112.6” (2860mm) x 83.3” x 92.1” (2115mm x 2340mm) | 12.3” (3360mm) x 83.3” x 92.1” (2115mm x 2340mm) | 126”x90.6”x87.8” (3200 mm x 2300 mm x 2230 mm) | 145.7”x90.6”x87.8” (3700 mm x 2300 mm x 2230 mm) | 165.4”x90.6”x87.8” (4200 mmx 2300 mm x 2230 mm) | 204.7”x90.6”x87.8” (5200 mm x 2300 mm x 2230 mm) |

| MODEL: | UTC-1440 | UTC-1640 | UTC-1660 | UTC-1740 | UTC-1760 | UTC-1840 | UTC-1860 | UTC 2240 | UTC 2260 | UTC 2280 | UTC 22120 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of control axis | 2 AXIS | 2 AXIS | 2 AXIS | 2 AXIS | |||||||

| Swing over the bed | 14.17” (360 mm) | 16.14” (410 mm) | 16.14” (410 mm) | Ø 17.12″ (435mm) | Ø 17.12″ (435mm) | Ø 18.11″ (460mm) | Ø 18.11″ (460mm) | Ø 22” (550 mm) | Ø 22” (550 mm) | Ø 22” (550 mm) | Ø 22” (550 mm) |

| Swing over the cross slide | 7.08” (180 mm) | 9.05” (230 mm) | 9.05” (230 mm) | ||||||||

| Distance between centers | 35” (880 mm) | 35” (880 mm) | 55” (1400 mm) | 37.40” (950mm) | 57.08” (1450mm) | 35.43” (900mm) | 55.11” (1400mm) | 34.25” (870 mm) | 53.93” (1370 mm) | 73.62” (1870 mm) | 113” (2870 mm) |

| Working length Max (4 way tool post / Hyd. P8 turret) | 29.52”(750mm)/ 24.8”(630mm) | 29.52”(750mm)/ 24.8”(630mm) | 49.61”(1260mm)/ 44.88”(1140mm) | 31.50” (800mm)/ 25.59” (650mm) | 51.18” (1300mm)/ 45.27” (1150mm) | 29.52” (750mm)/ 23.62” (600mm) | 49.21” (1250mm)/ 43.3” (1100mm) | 26.77” (680 mm) | 46.45” (1180 mm) | 66.14” (1680 mm) | 105.5” (2680 mm) |

| Working Dia. Max (4 way tool post / Hyd. P8 turret) | 6.7”(170mm)/ 6.29”(160mm) | 8.66”(220mm)/ 8.27”(210mm) | 8.66”(220mm)/ 8.27”(210mm) | 9.0” (230mm)8.66” (220mm) | 9.0” (230mm)8.66” (220mm) | 10.2” (260mm)/ 9.84” (250mm) | 10.2” (260mm)/ 9.84” (250mm) | Ø 12.8” (325 mm) | Ø 12.8” (325 mm) | Ø 12.8” (325 mm) | Ø 12.8” (325 mm) |

| Bed Width | 10.236” (260 mm) | 10.236” (260 mm) | 10.236” (260 mm) | 12” (305mm) | 12” (305mm) | 12” (305mm) | 12” (305mm) | 13.58” (345 mm) | 13.58” (345 mm) | 13.58” (345 mm) | 13.58” (345 mm) |

| Bed Ways (induction hardened & ground) | 3 “V”, 3 flat | 3 “V”, 3 flat | 3 “V”, 3 flat | 2 “V”, 2 flat | 2 “V”, 2 flat | 2 “V”, 2 flat | 2 “V”, 2 flat | ||||

| Cross slide (X) travel | 8.07” (205 mm) | 8.5” (216 mm) | 9.05” (230mm) | 9.05” (230mm) | 9.05” (230mm) | 9.05” (230mm) | 11.8” (300 mm) | 11.8” (300 mm) | 11.8” (300 mm) | 11.8” (300 mm) | |

| Longitudinal (Z) travel | 32.08” (815 mm) | 32.08” (815 mm) | 52.16” (1325 mm) | 35.43” (900mm) | 55.11” (1400mm) | 33.46” (850mm) | 53.15” (1350mm) | 30.7” (780 mm) | 50.4” (1280 mm) | 70.1” (1780 mm) | 109.4” (2780 mm) |

| Spindle nose, Standard | Camlock D1-6 or Optional ASA A1-6 | Camlock D1-6 or Optional ASA A1-7 | Camlock D1-6 or Optional ASA A1-8 | D1-6 MT (OPT. A1-6) | D1-6 MT (OPT. A1-6) | A2-6, Ø69 mm | A2-6, Ø69 mm | ASA A2-8, Ø 3.8” (97 mm) | ASA A2-8, Ø 3.8” (97 mm) | ASA A2-8, Ø 3.8” (97 mm) | ASA A2-8, Ø 3.8” (97 mm) |

| Spindle bore | 2.066” (52.5 mm) | 2.066” (52.5 mm) | 2.066” (52.5 mm) | Ø 2.06” (52.5mm), OPT. Ø 2” (51mm) | Ø 2.06” (52.5mm), OPT. Ø 2” (51mm) | Ø 2.56″ (65mm) | Ø 2.56″ (65mm) | Ø 3.5” (91 mm) / Ø 3.07” (78 mm) | Ø 3.5” (91 mm) / Ø 3.07” (78 mm) | Ø 3.5” (91 mm) / Ø 3.07” (78 mm) | Ø 3.5” (91 mm) / Ø 3.07” (78 mm) |

| Spindle taper | No. 6 MT | No. 6 MT | No. 6 MT | No. 6 MT | No. 6 MT | Taper 1/20 | Taper 1/20 | Taper 1/20 | Taper 1/20 | Taper 1/20 | Taper 1/20 |

| Spindle speeds | 25~3000 RPM (Pneumatic Auto-Shift) | 25~3000 RPM (Pneumatic Auto-Shift) | 25~3000 RPM (Pneumatic Auto-Shift) | Infinitely variable | Infinitely variable | Infinitely variable | Infinitely variable | Infinitely variable | Infinitely variable | Infinitely variable | Infinitely variable |

| Range | L: 25~480 RPM (Infinitely Variable)H: 481~3000 RPM (Infinitely Variable) | L: 25~480 RPM (Infinitely Variable)H: 481~3000 RPM (Infinitely Variable) | L: 25~480 RPM (Infinitely Variable)H: 481~3000 RPM (Infinitely Variable) | L: 30 ~ 450 RPMH: 451 ~ 2800 RPM | L: 30 ~ 450 RPMH: 451 ~ 2800 RPM | L: 270 ~ 830 RPM H: 831 ~ 2500 RPM | L: 270 ~ 830 RPM H: 831 ~ 2500 RPM | 35-3,500 rpm | 35-3,500 rpm | 35-3,500 rpm | 35-3,500 rpm |

| Gear steps | Pneumatic change 2 steps | Pneumatic change 2 steps | Pneumatic change 2 steps | Pneumatic change 2 steps | |||||||

| Main spindle motor | 10 HP (7.5 Kw) / 30 min rated 15HP (11Kw) | 11 HP (7.5 Kw) / 30 min rated 15HP (11Kw) | 12 HP (7.5 Kw) / 30 min rated 15HP (11Kw) | AC 7.5 HP (5.5 kW) | AC 7.5 HP (5.5 kW) | STD AC 11HP (7.5 kW)/ STD AC 15 HP (11 kW) | STD AC 11HP (7.5 kW)/ STD AC 15 HP (11 kW) | AC 12 HP (9 kW) wide range heavy duty Fanuc AC spindle motor | AC 12 HP (9 kW) wide range heavy duty Fanuc AC spindle motor | AC 12 HP (9 kW) wide range heavy duty Fanuc AC spindle motor | AC 12 HP (9 kW) wide range heavy duty Fanuc AC spindle motor |

| Tool station: | STD. Manual 4 way tool post; Optional: Elec. H4 or Hydraulic P8 turret | STD. Manual 4 way tool post; Optional: Elec. H4 or Hydraulic P8 turret | STD. Manual 4 way tool post; Optional: Elec. H4 or Hydraulic P8 turret | Manual 4-way tool post (STD) | Manual 4-way tool post (STD) | Manual 4-way tool post (STD) | Manual 4-way tool post (STD) | ||||

| Size of external turning tool | Tool section 0.78” (20mm). | Tool section 0.78” (20mm). | Tool section 0.78” (20mm). | 1” (25 mm) | 1” (25 mm) | 1” (25 mm) | 1” (25 mm) | ||||

| Boring Bar diameter | 0.78” (20mm). | 0.78” (20mm). | 0.78” (20mm). | Manual 4 way tool post / Ø 0.79” (20mm) | Manual 4 way tool post / Ø 0.98” (25mm) | Manual 4 way tool post / Ø 0.98” (25mm) | |||||

| Quill diameter | 2.283” (58 mm) | 2.283” (58 mm) | 2.283” (58 mm) | Ø 2.67” (68mm) | Ø 2.67” (68mm) | Ø 2.67” (68mm) | Ø 2.67” (68mm) | Ø 3.35” (85 mm) | Ø 3.35” (85 mm) | Ø 3.35” (85 mm) | Ø 3.35” (85 mm) |

| Quill taper | # 4 MT | # 4 MT | # 4 MT | MT No. 4 | MT No. 5 | #5 MT | #5 MT | #5 MT | #5 MT | ||

| Quill travel | 5.5” (140 mm) | 5.5” (140 mm) | 5.5” (140 mm) | 6” (153mm) | 6” (153mm) | 6” (153mm) | 6” (153mm) | 7” (178 mm) | 7” (178 mm) | 7” (178 mm) | 7” (178 mm) |

| AC servo motor ( X-axis / Z-axis ) | 0.85 kW 5.39 N.m/ 1.3 kW 8.34 N.m | 0.85 kW 5.39 N.m/ 1.3 kW 8.34 N.m | 7.0N.m ~ FANUC ß8 / 3000is | 7.0N.m ~ FANUC ß8 / 3000is | |||||||

| Servo drive motors (X / Z) | 1 HP (0.75 kW, 3.5 Nm)/ 1.61 HP (1.2 kW, 7 Nm) | 1 HP (0.75 kW, 3.5 Nm)/ 1.61 HP (1.2 kW, 7 Nm) | 1 HP (0.75 kW, 3.5 Nm)/ 1.61 HP (1.2 kW, 7 Nm) | ||||||||

| Ball screw Dia. (X / Z) | 0.787” (20 mm) (P5, C5)/ 1.260” (32 mm) (P10, C5) | 0.787” (20 mm) (P5, C5)/ 1.260” (32 mm) (P10, C5) | 0.787” (20 mm) (P5, C5)/ 1.260” (32 mm) (P10, C5) | Ø 0.787” (20 mm) P5 C5/ Ø 1.57” (40 mm) P10 C5 | Ø 0.787” (20 mm) P5 C5/ Ø 1.57” (40 mm) P10 C5 | Ø 1.57″ (20mm) P10 C5/ Ø 0.787″ (40mm) P5 C5 | Ø 1.57″ (20mm) P10 C5/ Ø 0.787″ (40mm) P5 C5 | Ø 0.98”(25 mm) P5 C5/ Ø 1.97” (50 mm) P10 C5 | Ø 0.98”(25 mm) P5 C5/ Ø 1.97” (50 mm) P10 C5 | Ø 0.98”(25 mm) P5 C5/ Ø 1.97” (50 mm) P10 C5 | Ø 0.98”(25 mm) P5 C5/ Ø 2.48” (63 mm) P10 C5 |

| Rapid traverse (X / Z) | 295 IPM (7.5MPM)/ 394 IPM (10MPM) | 295 IPM (7.5MPM)/ 394 IPM (10MPM) | 295 IPM (7.5MPM)/ 394 IPM (10MPM) | 196.8 ipm (5 m/min) / 295.3 ipm (7.5 m/min) | 196.8 ipm (5 m/min) / 295.3 ipm (7.5 m/min) | 295 ipm (7.5 m/min) / 394 ipm (10 m/min) | 295 ipm (7.5 m/min) / 394 ipm (10 m/min) | X = 295 ipm (7.5 mpm)Z = 394 ipm (10mpm) | X = 295 ipm (7.5 mpm)Z = 394 ipm (10mpm) | X = 295 ipm (7.5 mpm)Z = 394 ipm (10mpm) | X = 295 ipm (7.5 mpm)Z = 394 ipm (10mpm) |

| Positioning accuracy | ±0.0002” (±0.005 mm) | ±0.0002” (±0.005 mm) | ±0.0002” (±0.005 mm) | ± 0.0005” (0.01 mm) | ± 0.0005” (0.01 mm) | ± 0.0005” (0.01 mm) | ± 0.0005” (0.01 mm) | ||||

| Repeatability | ±0.0002” (±0.005 mm) | ±0.0002” (±0.005 mm) | ±0.0002” (±0.005 mm) | ± 0.0002” (0.005 mm) | ± 0.0002” (0.005 mm) | ± 0.0002” (0.005 mm) | ± 0.0002” (0.005 mm) | ||||

| Resolution | ±0.0001” (±0.00254 mm) | ±0.0001” (±0.00254 mm) | ±0.0001” (±0.00254 mm) | ± 0.0001” (0.002 mm) | ± 0.0001” (0.002 mm) | ± 0.0001” (0.002 mm) | ± 0.0001” (0.002 mm) | ||||

| Hydraulic tank | STD 5.5 gal (25 L), OPT 8.8 gal (40 L) | STD 5.5 gal (25 L), OPT 8.8 gal (40 L) | STD 5.5 gal (25 L), OPT 8.8 gal (40 L) | STD 5.5 gal (25 L), OPT 8.8 gal (40 L) | 6.6 gal. (25 liters) – STD , 10.5 gal. (40 liters) – Optional | 6.6 gal. (25 liters) – STD , 10.5 gal. (40 liters) – Optional | 6.6 gal. (25 liters) – STD , 10.5 gal. (40 liters) – Optional | 6.6 gal. (25 liters) – STD , 10.5 gal. (40 liters) – Optional | |||

| Coolant tank | 50L (11gl) | 50L (11gl) | 70L (15.4gl) | 13.2 gal (60 L) | 19.7 gal (85 L) | 13.2 gal (60 L) | 19.7 gal (85 L) | 15.85 gal. (60 liters) | 31.70 gal. (120 liters) | 47.5 gal. (180 liters) | 63.40 gal. (240 liters) |

| Hydraulic oil pump | OPT. 1HP (0.75kw) | OPT. 1HP (0.75kw) | OPT. 2HP (1.5kw) | OPT. 1 HP (0.75 kW), OPT. 2 HP (1.5kW) | OPT. 1 HP (0.75 kW), OPT. 2 HP (1.5kW) | OPT. 1HP (0.75 kW), OPT. 2HP (1.5kW) | |||||

| Forced lubrication for headstock | ¼ HP(0.18KW) | ¼ HP(0.18KW) | ¼ HP(0.18KW) | ¼ HP | ¼ HP | ¼ HP | ¼ HP | ||||

| Coolant pump | 70L (15.4gl) | 70L (15.4gl) | 70L (15.4gl) | 1/6 HP | 1/6 HP | 1/6 HP | 1/6 HP | ||||

| Weight (Net/Gross) Approx. | 4629 lbs (2100 Kgs.)/ 5732 lbs (2600 Kgs.) | 4739 lbs (2150 Kgs.)/ 5842 lbs (2650 Kgs.) | 4960lbs (2250 Kgs.)/ 6062 lbs (2750Kgs.) | 4739 lbs / 5842 lbs 2150 kgs / 2650 kgs) | 5291 lbs / 6393 lbs (2400 kgs/2900 kgs) | 5170 lbs / 6270 lbs (2350 kgs / 2850 kgs) | 5720 lbs / 6820 lbs (2600 kgs/3100 kgs) | 4050 kg/4450 kg | 4400 kg/4900 kg | 4800 kg/5400 kg | 5300 kg/6000 kg |

| Packing Sizes (L x W x H) | 97.24”(2470mm) x 80”(2030mm) x 87”(2200mm) | 97.24”(2470mm) x 80”(2030mm) x 87”(2200mm) | 117”(2980mm) x 80”(2030mm) x 87”(2200mm) | 104.72” (2660m) x 79.33” x 88.2” (2015mm x 2240mm) | 124.4” (3160mm) x 79.33” x 88.2” (2015mm x 2240mm) | 112.6” (2860mm) x 83.3” x 92.1” (2115mm x 2340mm) | 12.3” (3360mm) x 83.3” x 92.1” (2115mm x 2340mm) | 126”x90.6”x87.8” (3200 mm x 2300 mm x 2230 mm) | 145.7”x90.6”x87.8” (3700 mm x 2300 mm x 2230 mm) | 165.4”x90.6”x87.8” (4200 mmx 2300 mm x 2230 mm) | 204.7”x90.6”x87.8” (5200 mm x 2300 mm x 2230 mm) |

| MODEL: | UTC-1440 | UTC-1640 | UTC-1660 | UTC-1740 | UTC-1760 | UTC-1840 | UTC-1860 | UTC 2240 | UTC 2260 | UTC 2280 | UTC 22120 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of control axis | 2 AXIS | 2 AXIS | 2 AXIS | 2 AXIS | |||||||

| Swing over the bed | 14.17” (360 mm) | 16.14” (410 mm) | 16.14” (410 mm) | Ø 17.12″ (435mm) | Ø 17.12″ (435mm) | Ø 18.11″ (460mm) | Ø 18.11″ (460mm) | Ø 22” (550 mm) | Ø 22” (550 mm) | Ø 22” (550 mm) | Ø 22” (550 mm) |

| Swing over the cross slide | 7.08” (180 mm) | 9.05” (230 mm) | 9.05” (230 mm) | ||||||||

| Distance between centers | 35” (880 mm) | 35” (880 mm) | 55” (1400 mm) | 37.40” (950mm) | 57.08” (1450mm) | 35.43” (900mm) | 55.11” (1400mm) | 34.25” (870 mm) | 53.93” (1370 mm) | 73.62” (1870 mm) | 113” (2870 mm) |

| Working length Max (4 way tool post / Hyd. P8 turret) | 29.52”(750mm)/ 24.8”(630mm) | 29.52”(750mm)/ 24.8”(630mm) | 49.61”(1260mm)/ 44.88”(1140mm) | 31.50” (800mm)/ 25.59” (650mm) | 51.18” (1300mm)/ 45.27” (1150mm) | 29.52” (750mm)/ 23.62” (600mm) | 49.21” (1250mm)/ 43.3” (1100mm) | 26.77” (680 mm) | 46.45” (1180 mm) | 66.14” (1680 mm) | 105.5” (2680 mm) |

| Working Dia. Max (4 way tool post / Hyd. P8 turret) | 6.7”(170mm)/ 6.29”(160mm) | 8.66”(220mm)/ 8.27”(210mm) | 8.66”(220mm)/ 8.27”(210mm) | 9.0” (230mm)8.66” (220mm) | 9.0” (230mm)8.66” (220mm) | 10.2” (260mm)/ 9.84” (250mm) | 10.2” (260mm)/ 9.84” (250mm) | Ø 12.8” (325 mm) | Ø 12.8” (325 mm) | Ø 12.8” (325 mm) | Ø 12.8” (325 mm) |

| Bed Width | 10.236” (260 mm) | 10.236” (260 mm) | 10.236” (260 mm) | 12” (305mm) | 12” (305mm) | 12” (305mm) | 12” (305mm) | 13.58” (345 mm) | 13.58” (345 mm) | 13.58” (345 mm) | 13.58” (345 mm) |

| Bed Ways (induction hardened & ground) | 3 “V”, 3 flat | 3 “V”, 3 flat | 3 “V”, 3 flat | 2 “V”, 2 flat | 2 “V”, 2 flat | 2 “V”, 2 flat | 2 “V”, 2 flat | ||||

| Cross slide (X) travel | 8.07” (205 mm) | 8.5” (216 mm) | 9.05” (230mm) | 9.05” (230mm) | 9.05” (230mm) | 9.05” (230mm) | 11.8” (300 mm) | 11.8” (300 mm) | 11.8” (300 mm) | 11.8” (300 mm) | |

| Longitudinal (Z) travel | 32.08” (815 mm) | 32.08” (815 mm) | 52.16” (1325 mm) | 35.43” (900mm) | 55.11” (1400mm) | 33.46” (850mm) | 53.15” (1350mm) | 30.7” (780 mm) | 50.4” (1280 mm) | 70.1” (1780 mm) | 109.4” (2780 mm) |

| Spindle nose, Standard | Camlock D1-6 or Optional ASA A1-6 | Camlock D1-6 or Optional ASA A1-7 | Camlock D1-6 or Optional ASA A1-8 | D1-6 MT (OPT. A1-6) | D1-6 MT (OPT. A1-6) | A2-6, Ø69 mm | A2-6, Ø69 mm | ASA A2-8, Ø 3.8” (97 mm) | ASA A2-8, Ø 3.8” (97 mm) | ASA A2-8, Ø 3.8” (97 mm) | ASA A2-8, Ø 3.8” (97 mm) |

| Spindle bore | 2.066” (52.5 mm) | 2.066” (52.5 mm) | 2.066” (52.5 mm) | Ø 2.06” (52.5mm), OPT. Ø 2” (51mm) | Ø 2.06” (52.5mm), OPT. Ø 2” (51mm) | Ø 2.56″ (65mm) | Ø 2.56″ (65mm) | Ø 3.5” (91 mm) / Ø 3.07” (78 mm) | Ø 3.5” (91 mm) / Ø 3.07” (78 mm) | Ø 3.5” (91 mm) / Ø 3.07” (78 mm) | Ø 3.5” (91 mm) / Ø 3.07” (78 mm) |

| Spindle taper | No. 6 MT | No. 6 MT | No. 6 MT | No. 6 MT | No. 6 MT | Taper 1/20 | Taper 1/20 | Taper 1/20 | Taper 1/20 | Taper 1/20 | Taper 1/20 |

| Spindle speeds | 25~3000 RPM (Pneumatic Auto-Shift) | 25~3000 RPM (Pneumatic Auto-Shift) | 25~3000 RPM (Pneumatic Auto-Shift) | Infinitely variable | Infinitely variable | Infinitely variable | Infinitely variable | Infinitely variable | Infinitely variable | Infinitely variable | Infinitely variable |

| Range | L: 25~480 RPM (Infinitely Variable)H: 481~3000 RPM (Infinitely Variable) | L: 25~480 RPM (Infinitely Variable)H: 481~3000 RPM (Infinitely Variable) | L: 25~480 RPM (Infinitely Variable)H: 481~3000 RPM (Infinitely Variable) | L: 30 ~ 450 RPMH: 451 ~ 2800 RPM | L: 30 ~ 450 RPMH: 451 ~ 2800 RPM | L: 270 ~ 830 RPM H: 831 ~ 2500 RPM | L: 270 ~ 830 RPM H: 831 ~ 2500 RPM | 35-3,500 rpm | 35-3,500 rpm | 35-3,500 rpm | 35-3,500 rpm |

| Gear steps | Pneumatic change 2 steps | Pneumatic change 2 steps | Pneumatic change 2 steps | Pneumatic change 2 steps | |||||||

| Main spindle motor | 10 HP (7.5 Kw) / 30 min rated 15HP (11Kw) | 11 HP (7.5 Kw) / 30 min rated 15HP (11Kw) | 12 HP (7.5 Kw) / 30 min rated 15HP (11Kw) | AC 7.5 HP (5.5 kW) | AC 7.5 HP (5.5 kW) | STD AC 11HP (7.5 kW)/ STD AC 15 HP (11 kW) | STD AC 11HP (7.5 kW)/ STD AC 15 HP (11 kW) | AC 12 HP (9 kW) wide range heavy duty Fanuc AC spindle motor | AC 12 HP (9 kW) wide range heavy duty Fanuc AC spindle motor | AC 12 HP (9 kW) wide range heavy duty Fanuc AC spindle motor | AC 12 HP (9 kW) wide range heavy duty Fanuc AC spindle motor |

| Tool station: | STD. Manual 4 way tool post; Optional: Elec. H4 or Hydraulic P8 turret | STD. Manual 4 way tool post; Optional: Elec. H4 or Hydraulic P8 turret | STD. Manual 4 way tool post; Optional: Elec. H4 or Hydraulic P8 turret | Manual 4-way tool post (STD) | Manual 4-way tool post (STD) | Manual 4-way tool post (STD) | Manual 4-way tool post (STD) | ||||

| Size of external turning tool | Tool section 0.78” (20mm). | Tool section 0.78” (20mm). | Tool section 0.78” (20mm). | 1” (25 mm) | 1” (25 mm) | 1” (25 mm) | 1” (25 mm) | ||||

| Boring Bar diameter | 0.78” (20mm). | 0.78” (20mm). | 0.78” (20mm). | Manual 4 way tool post / Ø 0.79” (20mm) | Manual 4 way tool post / Ø 0.98” (25mm) | Manual 4 way tool post / Ø 0.98” (25mm) | |||||

| Quill diameter | 2.283” (58 mm) | 2.283” (58 mm) | 2.283” (58 mm) | Ø 2.67” (68mm) | Ø 2.67” (68mm) | Ø 2.67” (68mm) | Ø 2.67” (68mm) | Ø 3.35” (85 mm) | Ø 3.35” (85 mm) | Ø 3.35” (85 mm) | Ø 3.35” (85 mm) |

| Quill taper | # 4 MT | # 4 MT | # 4 MT | MT No. 4 | MT No. 5 | #5 MT | #5 MT | #5 MT | #5 MT | ||

| Quill travel | 5.5” (140 mm) | 5.5” (140 mm) | 5.5” (140 mm) | 6” (153mm) | 6” (153mm) | 6” (153mm) | 6” (153mm) | 7” (178 mm) | 7” (178 mm) | 7” (178 mm) | 7” (178 mm) |

| AC servo motor ( X-axis / Z-axis ) | 0.85 kW 5.39 N.m/ 1.3 kW 8.34 N.m | 0.85 kW 5.39 N.m/ 1.3 kW 8.34 N.m | 7.0N.m ~ FANUC ß8 / 3000is | 7.0N.m ~ FANUC ß8 / 3000is | |||||||

| Servo drive motors (X / Z) | 1 HP (0.75 kW, 3.5 Nm)/ 1.61 HP (1.2 kW, 7 Nm) | 1 HP (0.75 kW, 3.5 Nm)/ 1.61 HP (1.2 kW, 7 Nm) | 1 HP (0.75 kW, 3.5 Nm)/ 1.61 HP (1.2 kW, 7 Nm) | ||||||||

| Ball screw Dia. (X / Z) | 0.787” (20 mm) (P5, C5)/ 1.260” (32 mm) (P10, C5) | 0.787” (20 mm) (P5, C5)/ 1.260” (32 mm) (P10, C5) | 0.787” (20 mm) (P5, C5)/ 1.260” (32 mm) (P10, C5) | Ø 0.787” (20 mm) P5 C5/ Ø 1.57” (40 mm) P10 C5 | Ø 0.787” (20 mm) P5 C5/ Ø 1.57” (40 mm) P10 C5 | Ø 1.57″ (20mm) P10 C5/ Ø 0.787″ (40mm) P5 C5 | Ø 1.57″ (20mm) P10 C5/ Ø 0.787″ (40mm) P5 C5 | Ø 0.98”(25 mm) P5 C5/ Ø 1.97” (50 mm) P10 C5 | Ø 0.98”(25 mm) P5 C5/ Ø 1.97” (50 mm) P10 C5 | Ø 0.98”(25 mm) P5 C5/ Ø 1.97” (50 mm) P10 C5 | Ø 0.98”(25 mm) P5 C5/ Ø 2.48” (63 mm) P10 C5 |

| Rapid traverse (X / Z) | 295 IPM (7.5MPM)/ 394 IPM (10MPM) | 295 IPM (7.5MPM)/ 394 IPM (10MPM) | 295 IPM (7.5MPM)/ 394 IPM (10MPM) | 196.8 ipm (5 m/min) / 295.3 ipm (7.5 m/min) | 196.8 ipm (5 m/min) / 295.3 ipm (7.5 m/min) | 295 ipm (7.5 m/min) / 394 ipm (10 m/min) | 295 ipm (7.5 m/min) / 394 ipm (10 m/min) | X = 295 ipm (7.5 mpm)Z = 394 ipm (10mpm) | X = 295 ipm (7.5 mpm)Z = 394 ipm (10mpm) | X = 295 ipm (7.5 mpm)Z = 394 ipm (10mpm) | X = 295 ipm (7.5 mpm)Z = 394 ipm (10mpm) |

| Positioning accuracy | ±0.0002” (±0.005 mm) | ±0.0002” (±0.005 mm) | ±0.0002” (±0.005 mm) | ± 0.0005” (0.01 mm) | ± 0.0005” (0.01 mm) | ± 0.0005” (0.01 mm) | ± 0.0005” (0.01 mm) | ||||

| Repeatability | ±0.0002” (±0.005 mm) | ±0.0002” (±0.005 mm) | ±0.0002” (±0.005 mm) | ± 0.0002” (0.005 mm) | ± 0.0002” (0.005 mm) | ± 0.0002” (0.005 mm) | ± 0.0002” (0.005 mm) | ||||

| Resolution | ±0.0001” (±0.00254 mm) | ±0.0001” (±0.00254 mm) | ±0.0001” (±0.00254 mm) | ± 0.0001” (0.002 mm) | ± 0.0001” (0.002 mm) | ± 0.0001” (0.002 mm) | ± 0.0001” (0.002 mm) | ||||

| Hydraulic tank | STD 5.5 gal (25 L), OPT 8.8 gal (40 L) | STD 5.5 gal (25 L), OPT 8.8 gal (40 L) | STD 5.5 gal (25 L), OPT 8.8 gal (40 L) | STD 5.5 gal (25 L), OPT 8.8 gal (40 L) | 6.6 gal. (25 liters) – STD , 10.5 gal. (40 liters) – Optional | 6.6 gal. (25 liters) – STD , 10.5 gal. (40 liters) – Optional | 6.6 gal. (25 liters) – STD , 10.5 gal. (40 liters) – Optional | 6.6 gal. (25 liters) – STD , 10.5 gal. (40 liters) – Optional | |||

| Coolant tank | 50L (11gl) | 50L (11gl) | 70L (15.4gl) | 13.2 gal (60 L) | 19.7 gal (85 L) | 13.2 gal (60 L) | 19.7 gal (85 L) | 15.85 gal. (60 liters) | 31.70 gal. (120 liters) | 47.5 gal. (180 liters) | 63.40 gal. (240 liters) |

| Hydraulic oil pump | OPT. 1HP (0.75kw) | OPT. 1HP (0.75kw) | OPT. 2HP (1.5kw) | OPT. 1 HP (0.75 kW), OPT. 2 HP (1.5kW) | OPT. 1 HP (0.75 kW), OPT. 2 HP (1.5kW) | OPT. 1HP (0.75 kW), OPT. 2HP (1.5kW) | |||||

| Forced lubrication for headstock | ¼ HP(0.18KW) | ¼ HP(0.18KW) | ¼ HP(0.18KW) | ¼ HP | ¼ HP | ¼ HP | ¼ HP | ||||

| Coolant pump | 70L (15.4gl) | 70L (15.4gl) | 70L (15.4gl) | 1/6 HP | 1/6 HP | 1/6 HP | 1/6 HP | ||||

| Weight (Net/Gross) Approx. | 4629 lbs (2100 Kgs.)/ 5732 lbs (2600 Kgs.) | 4739 lbs (2150 Kgs.)/ 5842 lbs (2650 Kgs.) | 4960lbs (2250 Kgs.)/ 6062 lbs (2750Kgs.) | 4739 lbs / 5842 lbs 2150 kgs / 2650 kgs) | 5291 lbs / 6393 lbs (2400 kgs/2900 kgs) | 5170 lbs / 6270 lbs (2350 kgs / 2850 kgs) | 5720 lbs / 6820 lbs (2600 kgs/3100 kgs) | 4050 kg/4450 kg | 4400 kg/4900 kg | 4800 kg/5400 kg | 5300 kg/6000 kg |

| Packing Sizes (L x W x H) | 97.24”(2470mm) x 80”(2030mm) x 87”(2200mm) | 97.24”(2470mm) x 80”(2030mm) x 87”(2200mm) | 117”(2980mm) x 80”(2030mm) x 87”(2200mm) | 104.72” (2660m) x 79.33” x 88.2” (2015mm x 2240mm) | 124.4” (3160mm) x 79.33” x 88.2” (2015mm x 2240mm) | 112.6” (2860mm) x 83.3” x 92.1” (2115mm x 2340mm) | 12.3” (3360mm) x 83.3” x 92.1” (2115mm x 2340mm) | 126”x90.6”x87.8” (3200 mm x 2300 mm x 2230 mm) | 145.7”x90.6”x87.8” (3700 mm x 2300 mm x 2230 mm) | 165.4”x90.6”x87.8” (4200 mmx 2300 mm x 2230 mm) | 204.7”x90.6”x87.8” (5200 mm x 2300 mm x 2230 mm) |

* All Product Specs are Subject to Change at Any Time

One year or 2,000 hours from date of installation, (single shifting) whichever occurs first.

For parts and service contact our support team at:

or call

800.421.2105

*Applies to domestic sales only.