Bermaq Viscom Router Type Machining Center

OUTSTANDING FEATURES

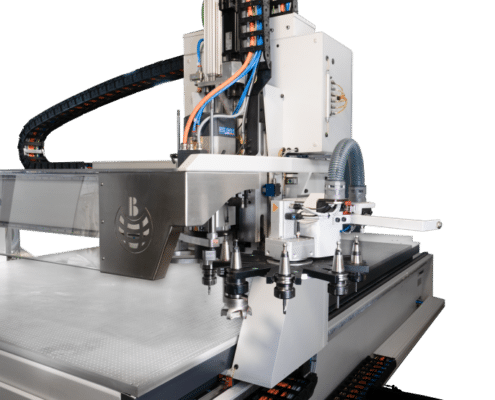

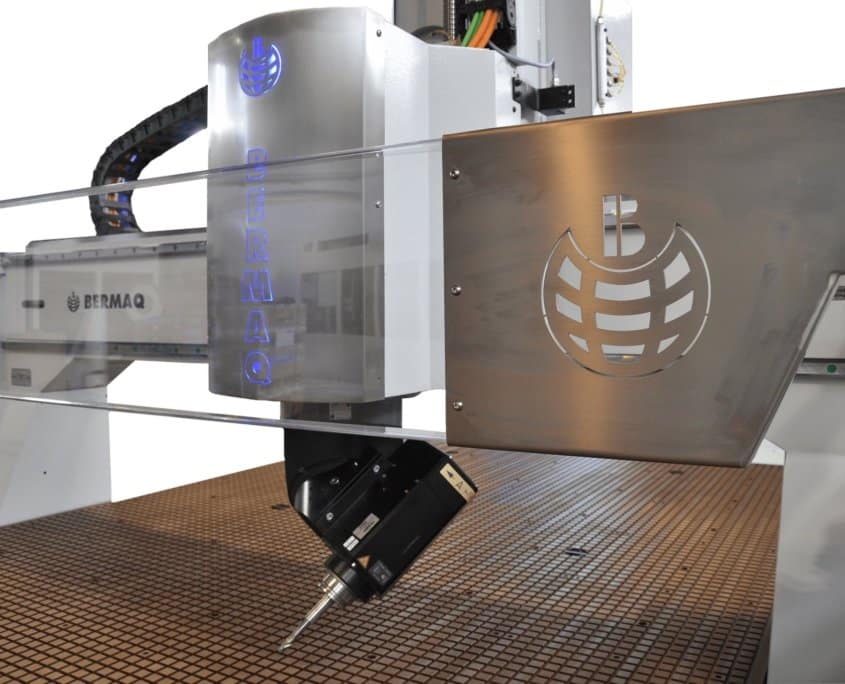

The numerical control milling machine VISCOM has been designed, fundamentally, to work at high speed a wide variety of materials (plastics, woods, aluminium, resins, composites, etc.) and applications. This industrial CNC machine stands out for its robustness, versatility and quality, offering a guarantee of unbeatable productivity.

Its equipment with recirculating ball screws allows high precision in the machining and ensures a high-quality finish. At the same time, its strong structure guarantees greater resistance to continuous work and high machining requirements.

Its compact design makes it a robust and modular CNC milling machine. Its structure allows easy customization of the machine with optimal solutions according to the production requirements of each client. This model has a wide range of custom-made solutions to suit the needs of each project.

The VISCOM CNC milling machine model has become one of the most popular thanks to its easy operation, reliability, speed and, above all, the quality and precision of the finishes.

It is an ideal machine for the sector of signage, machining and scenography, among others.

DESCRIPTION

Presenting Bermaq’s Viscom Router Type Machining Center. Viscom’s compact design turns it into a robust and modular CNC milling machine. Its structure enables an easier personalisation of the machine offering excellent solutions to the customers demands and production requirements. The Viscom model stands out for its easy utilization, reliability, high robustness and high speed.

*Note: Interested in more router type machining centers? Take a look at our SG L / XL / XXL and Viscom 5X bed mills. Or browse all machining centers offered by Lagun Engineering here.

Check us out on Instagram for more posts and videos!

SPECIFICATIONS

| Machine Model: | VISCOM | VISCOM 5X |

|---|---|---|

| Working Area: | ||

| X: | 61” (1550 mm) | 1,550 mm to 10,000 mm |

| Y: | 61” (1550 mm) | 1,000 mm up to 3,000 mm |

| Z: | 25.59” (650 mm) | 500 mm. |

| C: | Endless | Endless |

| A: | Endless | Endless |

| No. Working Areas: | 2 | 2 |

| Positioning speeds: | ||

| X: | 80 m / min | 55 m/min |

| Y: | 80 m / min | 55 m/min |

| Z: | 30 m / min | 20 m/min |

| C: | 75º/sec. | |

| A: | 75º/sec. | |

| Number Of Axes: | 3 | 5 |

| Milling Head: | 8kW to 15kW – ISO30 or HSK-F63; liquid or air cooling system | HSK-F63 11kW, liquid cooling system |

| HSD ES929 Motor: | ||

| Motor power (S1) | 14.75 HP (11 kW) | |

| Nominal speed | 12,000 RPM | 12,000 rpm. |

| Maximum speed | 24,000 RPM | 20,000 rpm. |

| Cooling System Type | Liquid | Air/liquid tool cooling |

| Tool: | ||

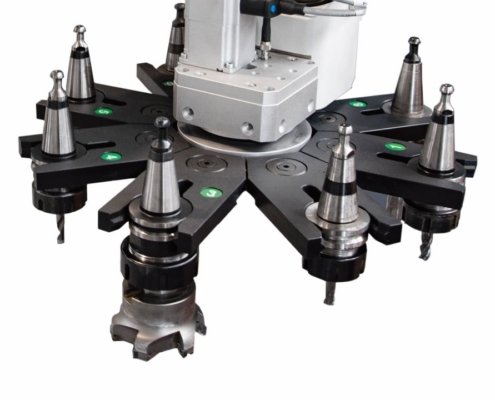

| Revolver type tool changer: | bridge 8 positions revolver, or bench 10 positions linear | double turret with 16 positions capacity located on the bridge |

| Probe for workpiece/tool calibration | BERMAQ | |

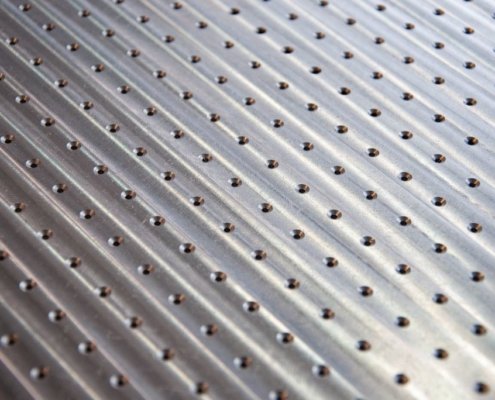

| Phenolic resin vacuum table | T-slotted | |

| Numerical Control | Fanuc 30iB | OSAI, SIEMENS or HEIDENHAIN |

| Remote fault diagnosis system | Included | |

| PROFIBUS Tech | Included |

| Machine Model: | VISCOM | VISCOM 5X |

|---|---|---|

| Working Area: | ||

| X: | 61” (1550 mm) | 1,550 mm to 10,000 mm |

| Y: | 61” (1550 mm) | 1,000 mm up to 3,000 mm |

| Z: | 25.59” (650 mm) | 500 mm. |

| C: | Endless | Endless |

| A: | Endless | Endless |

| No. Working Areas: | 2 | 2 |

| Positioning speeds: | ||

| X: | 80 m / min | 55 m/min |

| Y: | 80 m / min | 55 m/min |

| Z: | 30 m / min | 20 m/min |

| C: | 75º/sec. | |

| A: | 75º/sec. | |

| Number Of Axes: | 3 | 5 |

| Milling Head: | 8kW to 15kW – ISO30 or HSK-F63; liquid or air cooling system | HSK-F63 11kW, liquid cooling system |

| HSD ES929 Motor: | ||

| Motor power (S1) | 14.75 HP (11 kW) | |

| Nominal speed | 12,000 RPM | 12,000 rpm. |

| Maximum speed | 24,000 RPM | 20,000 rpm. |

| Cooling System Type | Liquid | Air/liquid tool cooling |

| Tool: | ||

| Revolver type tool changer: | bridge 8 positions revolver, or bench 10 positions linear | double turret with 16 positions capacity located on the bridge |

| Probe for workpiece/tool calibration | BERMAQ | |

| Phenolic resin vacuum table | T-slotted | |

| Numerical Control | Fanuc 30iB | OSAI, SIEMENS or HEIDENHAIN |

| Remote fault diagnosis system | Included | |

| PROFIBUS Tech | Included |

| Machine Model: | VISCOM | VISCOM 5X |

|---|---|---|

| Working Area: | ||

| X: | 61” (1550 mm) | 1,550 mm to 10,000 mm |

| Y: | 61” (1550 mm) | 1,000 mm up to 3,000 mm |

| Z: | 25.59” (650 mm) | 500 mm. |

| C: | Endless | Endless |

| A: | Endless | Endless |

| No. Working Areas: | 2 | 2 |

| Positioning speeds: | ||

| X: | 80 m / min | 55 m/min |

| Y: | 80 m / min | 55 m/min |

| Z: | 30 m / min | 20 m/min |

| C: | 75º/sec. | |

| A: | 75º/sec. | |

| Number Of Axes: | 3 | 5 |

| Milling Head: | 8kW to 15kW – ISO30 or HSK-F63; liquid or air cooling system | HSK-F63 11kW, liquid cooling system |

| HSD ES929 Motor: | ||

| Motor power (S1) | 14.75 HP (11 kW) | |

| Nominal speed | 12,000 RPM | 12,000 rpm. |

| Maximum speed | 24,000 RPM | 20,000 rpm. |

| Cooling System Type | Liquid | Air/liquid tool cooling |

| Tool: | ||

| Revolver type tool changer: | bridge 8 positions revolver, or bench 10 positions linear | double turret with 16 positions capacity located on the bridge |

| Probe for workpiece/tool calibration | BERMAQ | |

| Phenolic resin vacuum table | T-slotted | |

| Numerical Control | Fanuc 30iB | OSAI, SIEMENS or HEIDENHAIN |

| Remote fault diagnosis system | Included | |

| PROFIBUS Tech | Included |

* All Product Specs are Subject to Change at Any Time

One year or 2,000 hours from date of installation,(single shifting) whichever occurs first. For parts and service contact our support team at

PARTS@LAGUN.COM

or call

800.421.2105

*Applies to domestic sales only.