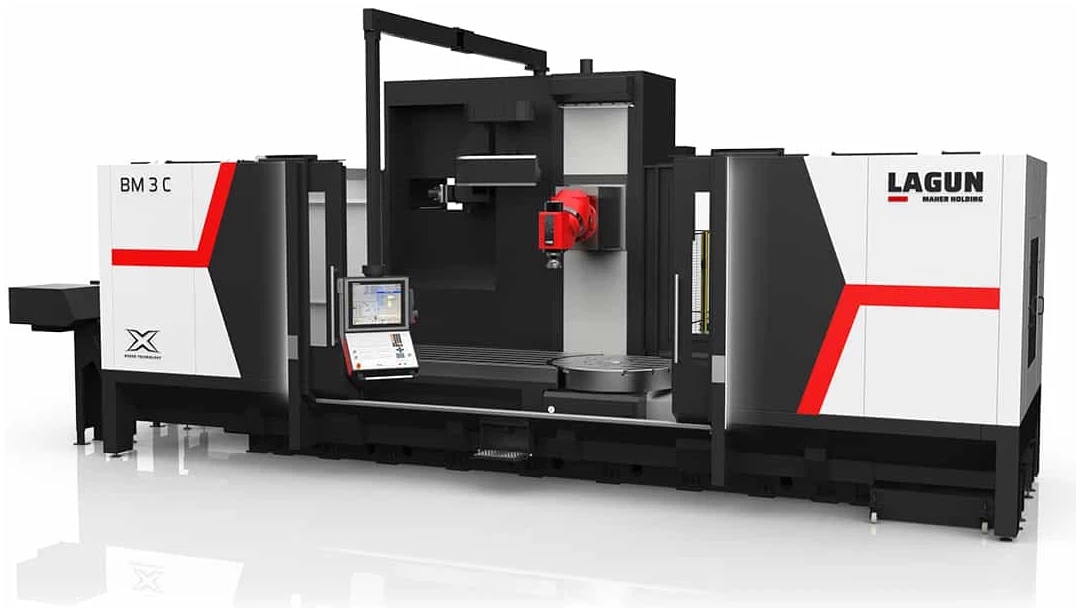

Lagun Maher Holding BM-C Bed Type Milling Machine with Integrated Rotary Table

OUTSTANDING FEATURES

Lagun Heavy Mill’s Bed Mill Model BM-C is very compact in its design but provides robust manufacturing capabilities and features the following key characteristics:

· Ø43.31” (Ø1100 mm) rotary table built in the table with a load capacity of 6 Tn.

· Complete table width 43.31” (1100mm).

· Tangential movement with hydraulically locked table 4425.37 ft-lb (6,000 Nm).

· Admissible torque during milling 7375.62 ft-lb (10,000 Nm).

In the LAGUN range of bed type milling machines, the BM C milling machine model is really a

BM C

combination of the usual BM bed type milling machine and a BM RT bed type milling machine with rotary table.

Flexibility: machine with a rotary table with a high load capacity and rectangular flat table also with good load capacity at the same

height. Workpiece machining is possible on both the complete table or on each one individually. With a longitudinal X-travel of 3, 4 or 5 meters.

Versatility: machine offering different milling possibilities, for long workpieces, workpieces requiring 5-sided milling, rotating workpieces, etc.

The milling machine is provided with an optimised working area and internal space for machining of different-shaped and sized workpieces, with excellent swarf and coolant removal.

The BM C design offers an ideal solution for machining a wide variety

DESCRIPTION

Lagun’s BM-C Bed Mill is a bed type mill with an integrated rotary table. With a compact and robust design, this milling machine offers application-oriented technological solutions while offering high profitability.

Lagun’s BM-C bed mill is built with a modular configuration, which means all models in this spectacular line have interchangeable slides, rams and columns. This design method endows each machine with enhanced rigidity, precision and ergonomic working comfort for the operator.

Benefits of this modular design system include:

–Increased versatility insures a speedy manufacturing process

–Easy customization with a greater degree of adaptability when configuring different structural elements

–Stronger machines as a result of design optimization, coupled with lean and simplified repetitive manufacturing

–Easy maintenance due to design – no superfluous elements

–Greater precision with the optimal configuration of slide/ram and roller/shoes

Additionally the sturdy, oversized mill bed comes with reinforced ribbing, fortifying its stability during heavy milling. The table, column, slide and ram systems have been studied and as a result designed with roller/shoes that exceed the manufacturing requirements. Designed to be as close to the column as possible, the mills ram placement ensures a sturdy column-slide-ram assembly. This results in a rigid and light slide for vertical movement. To correct any ram deflection during cross movement they come equipped with special wedges. With a load capacity of 6 ton (12,000 lbs), the mills hefty table is suited for heavy-duty and specific jobs.

*Note: Interested in more bed type milling machines? Take a look at our BM RT and BM-BL bed mills. Or browse all mill machining centers offered by Lagun Engineering here.

Check us out on Instagram for more posts and videos!

SPECIFICATIONS

| Model | BM 3 C | BM 4 C |

|---|---|---|

| Table surface | 78.74” + Ø 43.31” x 43.31” [ (2000mm + Ø 1100mm) x 1100mm] | (118.11”.+ Ø 43.31”) x 43.31” [(3000mm + Ø 1100mm) x 1100mm] |

| T slots | .28” x 0.87” x 6.30” (7mm x 22mm x 160mm) | .28” x 0.87” x 6.30” (7mm x 22mm x 160mm) |

| Longitudinal traverse= X | 118.11” (3000mm) | 157.48” (4000mm) |

| Cross traverse= Y | 51.18” (300mm) | 51.18” (300mm) |

| Vertical traverse= Z | 59.06”/ 78.74” (1500mm / 2000mm*) | 59.06”/ 78.74” (1500mm / 2000mm*) |

| Max. Weight on the table | 17.64lb + 13.23lb (80Kg + 60Kg) | 22.05lb + 13.23lb (10Kg + 60Kg) |

| Spindle taper | 50 DIN 69871/A + DIN 69872/A | 50 DIN 69871/A + DIN 69872/A |

| Speed range | 4000 / 6000* / 8000* RPM | 4000 / 6000* / 8000* RPM |

| Main motor power | 42HP-51HP/ 54HP-66 HP (31 – 38kW / 40 - 49* kW) | 42HP-51HP/ 54HP-66 HP (31 – 38kW / 40 - 49* kW) |

| Constant torque until 287 rpm | 758.21 ft-lb/ 1032.59 ft-lb (1028Nm / 1400* Nm) | 758.21 ft-lb/ 1032.59 ft-lb (1028Nm / 1400* Nm) |

| Rapid feed | 787.40 IPM / 1181.10 IPM (20 / 30* MPM) | 787.40 IPM / 1181.10 IPM (20 / 30* MPM) |

| Machine net weight | 48060.77lb (21800Kg) | 57320.18lb (26000Kg) |

| Model | BM 3 C | BM 4 C |

|---|---|---|

| Table surface | 78.74” + Ø 43.31” x 43.31” [ (2000mm + Ø 1100mm) x 1100mm] | (118.11”.+ Ø 43.31”) x 43.31” [(3000mm + Ø 1100mm) x 1100mm] |

| T slots | .28” x 0.87” x 6.30” (7mm x 22mm x 160mm) | .28” x 0.87” x 6.30” (7mm x 22mm x 160mm) |

| Longitudinal traverse= X | 118.11” (3000mm) | 157.48” (4000mm) |

| Cross traverse= Y | 51.18” (300mm) | 51.18” (300mm) |

| Vertical traverse= Z | 59.06”/ 78.74” (1500mm / 2000mm*) | 59.06”/ 78.74” (1500mm / 2000mm*) |

| Max. Weight on the table | 17.64lb + 13.23lb (80Kg + 60Kg) | 22.05lb + 13.23lb (10Kg + 60Kg) |

| Spindle taper | 50 DIN 69871/A + DIN 69872/A | 50 DIN 69871/A + DIN 69872/A |

| Speed range | 4000 / 6000* / 8000* RPM | 4000 / 6000* / 8000* RPM |

| Main motor power | 42HP-51HP/ 54HP-66 HP (31 – 38kW / 40 – 49* kW) | 42HP-51HP/ 54HP-66 HP (31 – 38kW / 40 – 49* kW) |

| Constant torque until 287 rpm | 758.21 ft-lb/ 1032.59 ft-lb (1028Nm / 1400* Nm) | 758.21 ft-lb/ 1032.59 ft-lb (1028Nm / 1400* Nm) |

| Rapid feed | 787.40 IPM / 1181.10 IPM (20 / 30* MPM) | 787.40 IPM / 1181.10 IPM (20 / 30* MPM) |

| Machine net weight | 48060.77lb (21800Kg) | 57320.18lb (26000Kg) |

| Model | BM 3 C | BM 4 C |

|---|---|---|

| Table surface | 78.74” + Ø 43.31” x 43.31” [ (2000mm + Ø 1100mm) x 1100mm] | (118.11”.+ Ø 43.31”) x 43.31” [(3000mm + Ø 1100mm) x 1100mm] |

| T slots | .28” x 0.87” x 6.30” (7mm x 22mm x 160mm) | .28” x 0.87” x 6.30” (7mm x 22mm x 160mm) |

| Longitudinal traverse= X | 118.11” (3000mm) | 157.48” (4000mm) |

| Cross traverse= Y | 51.18” (300mm) | 51.18” (300mm) |

| Vertical traverse= Z | 59.06”/ 78.74” (1500mm / 2000mm*) | 59.06”/ 78.74” (1500mm / 2000mm*) |

| Max. Weight on the table | 17.64lb + 13.23lb (80Kg + 60Kg) | 22.05lb + 13.23lb (10Kg + 60Kg) |

| Spindle taper | 50 DIN 69871/A + DIN 69872/A | 50 DIN 69871/A + DIN 69872/A |

| Speed range | 4000 / 6000* / 8000* RPM | 4000 / 6000* / 8000* RPM |

| Main motor power | 42HP-51HP/ 54HP-66 HP (31 – 38kW / 40 – 49* kW) | 42HP-51HP/ 54HP-66 HP (31 – 38kW / 40 – 49* kW) |

| Constant torque until 287 rpm | 758.21 ft-lb/ 1032.59 ft-lb (1028Nm / 1400* Nm) | 758.21 ft-lb/ 1032.59 ft-lb (1028Nm / 1400* Nm) |

| Rapid feed | 787.40 IPM / 1181.10 IPM (20 / 30* MPM) | 787.40 IPM / 1181.10 IPM (20 / 30* MPM) |

| Machine net weight | 48060.77lb (21800Kg) | 57320.18lb (26000Kg) |

* All Product Specs are Subject to Change at Any Time

One year or 2,000 hours from date of installation, (single shifting) whichever occurs first. For parts and service contact our support team at

or call

800.421.2105

*Applies to domestic sales only.